Off-Site Construction: Economic Advantages and Precast Concrete Solutions with Moldtech

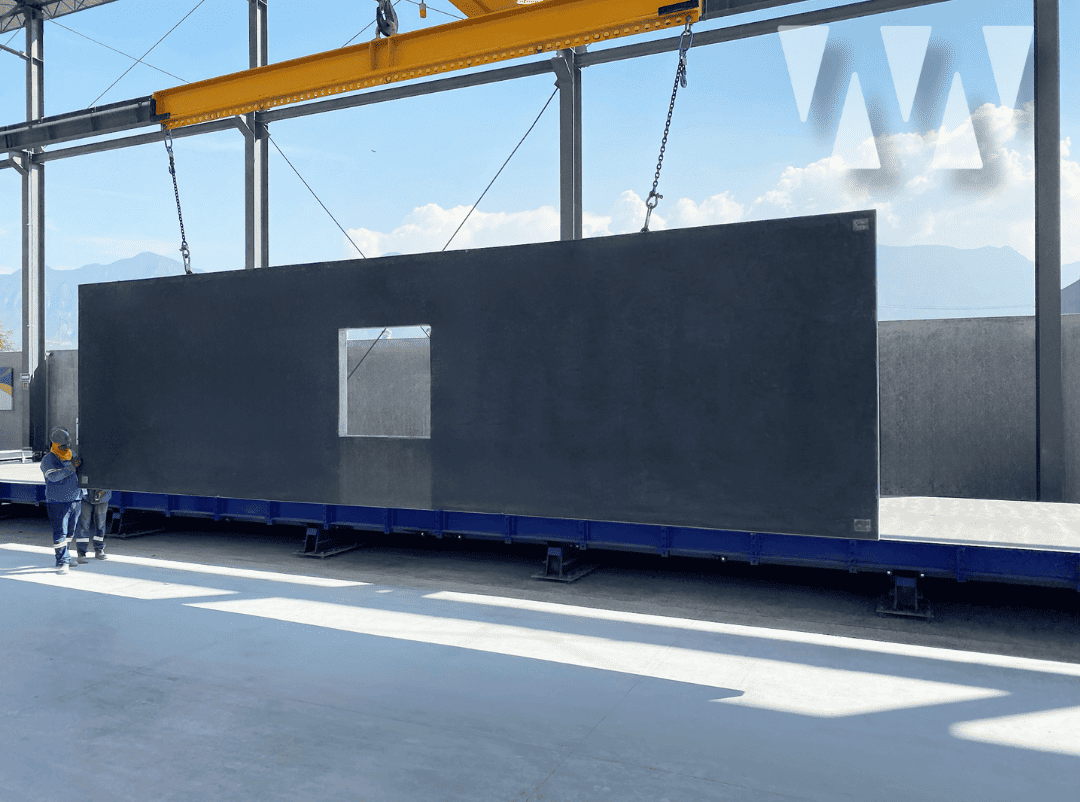

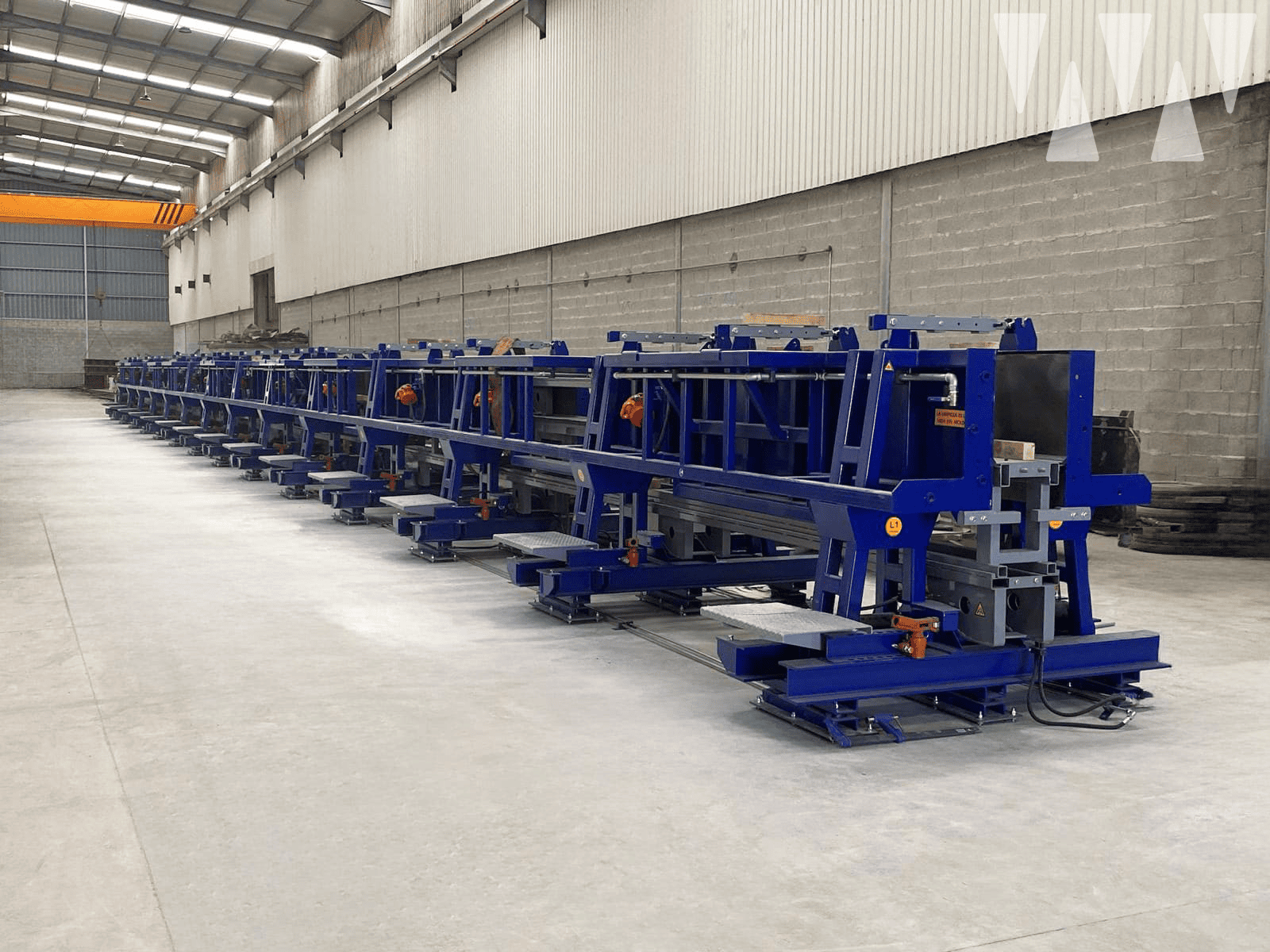

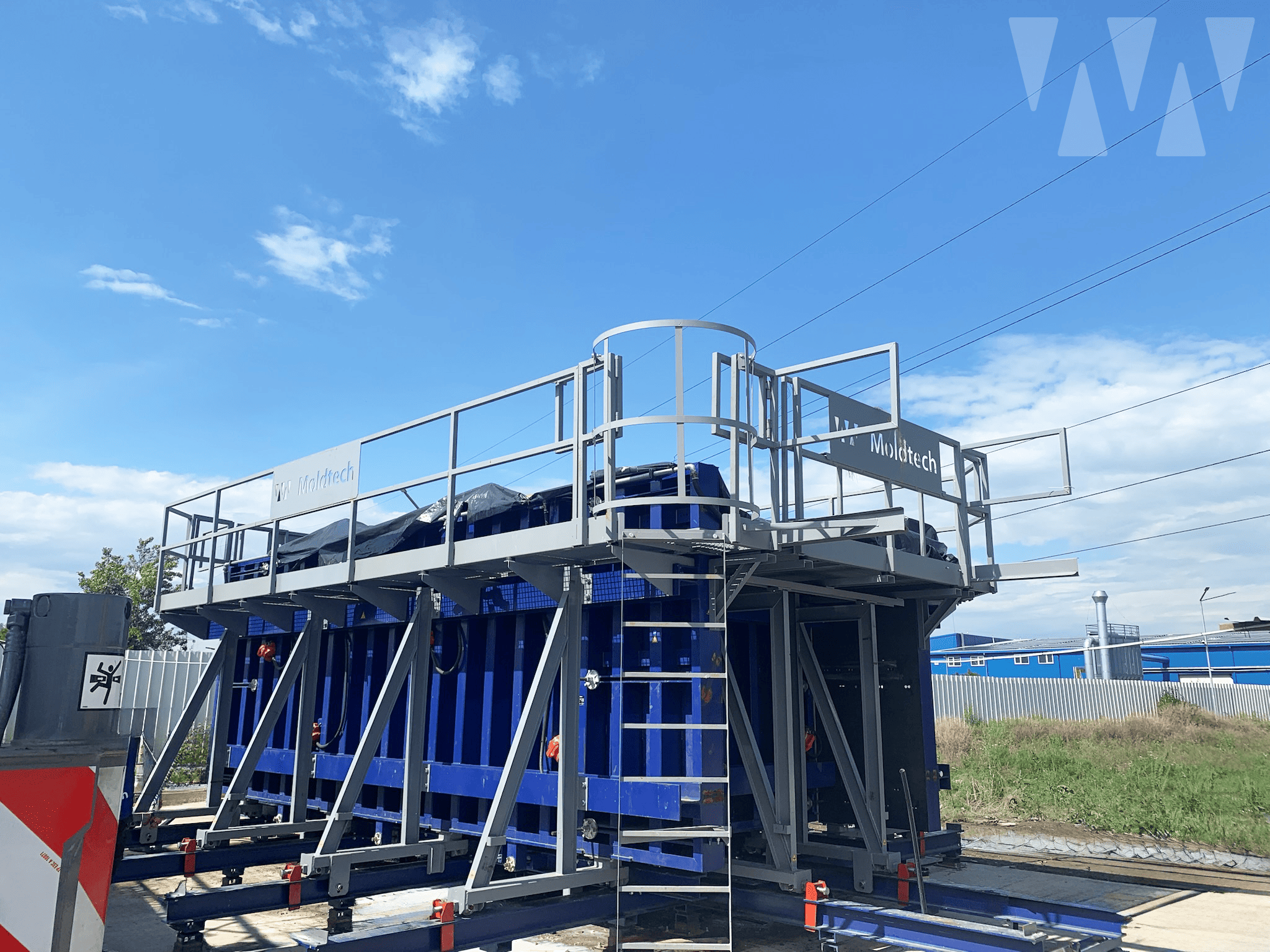

Off-Site construction: industrialising the way we build Off-Site construction is much more than moving part of the work from the jobsite to a factory. When we combine Off-Site construction, precast concrete and modular building, we are talking about a strategic shift in how projects are designed, costed and delivered. From our perspective at Moldtech, this […]

Off-Site Construction: Economic Advantages and Precast Concrete Solutions with Moldtech Read More »