Designed for high productivity of precast box culverts.

Do you want more information?

Contact an expert from our team now

- +34 955 444 190

- info@moldtechsl.es

Designed for high productivity of precast box culverts.

This equipment is designed for high productivity of precast box culverts, since it allows the use of dry cast method.

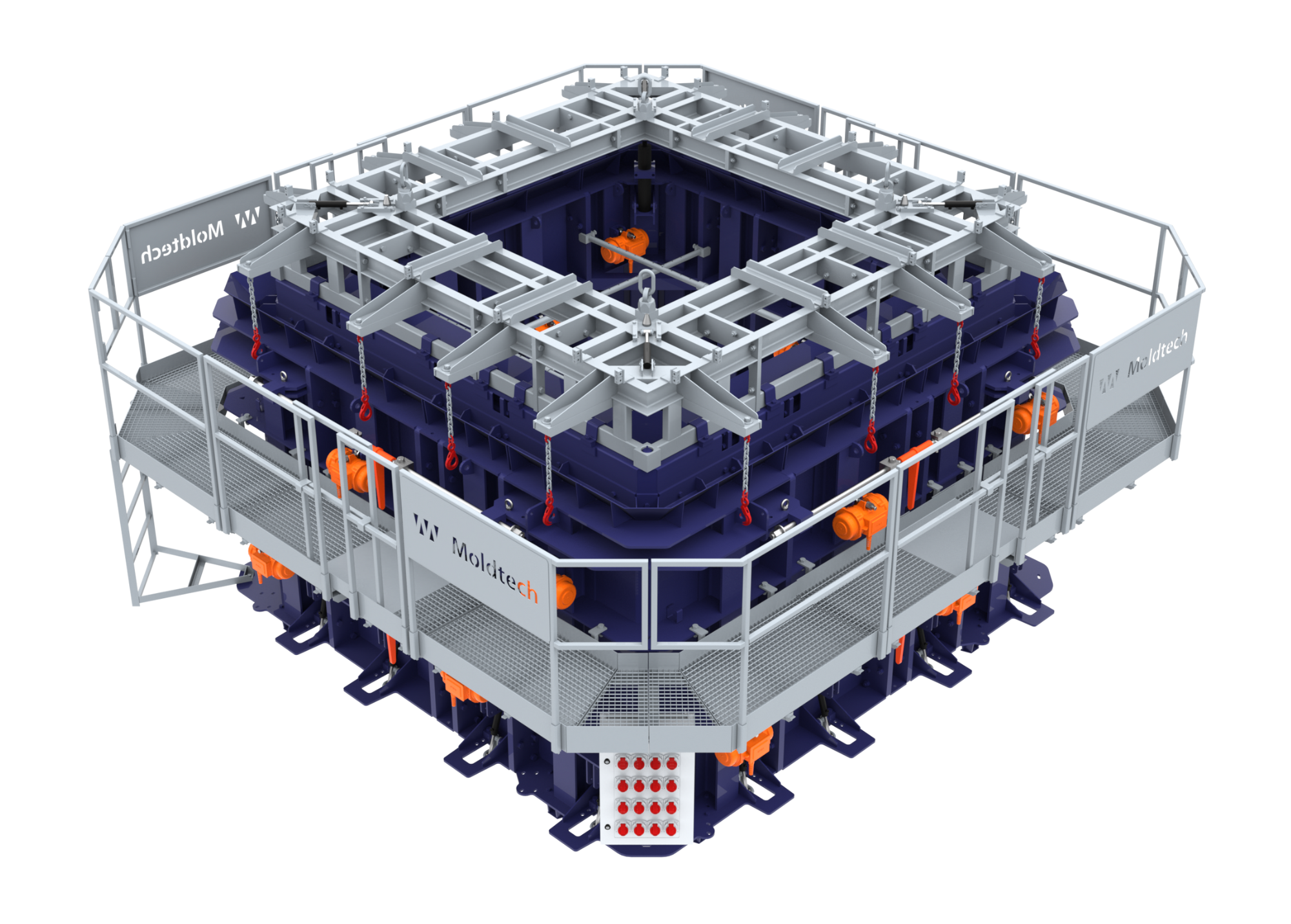

This equipment consists of the assembly of an inner and an outer formwork on the same base, with anchorage by a set of hydraulic clamps.

Both the base and the two formworks are made with a modular design, which allows the assembly of more or less elements to produce precast dry cast box culverts in different sizes, usually up to 3x3m. According to the elements assembled on the outer formwork, it is also possible to produce different thicknesses with the same system.

The assembly of the different formwork modules and the chassis is performed manually by screw-nut joints. The union flanks or brackets are machine-drilled, which ensures the tightness of the molding set.

At the same time, the mold has a chassis which is configurable in the same way that the elements already described. To this chassis, the pressing frame is attached and the inner and outer formworks are hooked.

As compacting system, the mold has a set of electric vibrators with variable frequency. By means of a movable control panel, this frequency can be varied and the most appropriate vibrators can be selected in each phase of the filling.

The production process begins after arranging a set of bases with the corresponding reinforcement and applying release agent to all the surfaces which will contact the concrete. The assembly of the pressing unit and the inner and outer formwork is placed on the first base and all the locking systems are activated from the electrical board of the hydraulic unit.

Then, the amount of concrete needed is gradually poured and electric vibrators are activated sequentially to apply the vibration with different frequencies. Once the pouring of the concrete is completed, the pressing operation is performed with the complement of vibration.

Finally, the hydraulic clamps are deactivated and the pressing frame is hoisted with the inner and outer formwork, obtaining the concrete piece finished on the basis. After some hours which will depend on the quality of the cement and the mixture used, the prefabricated concrete frame will harden and may already be manipulated for its storage.

The production process is repeated on the other basis. This system allows a continuous production and the user factories have succeeded in producing up to 10 units per 8-hour shift when using an optimized formulation of concrete and the force work is qualified.

C/ Polysol Uno, 40 Pol. Industrial Piedra Hincada 41500 Alcalá de Guadaíra Seville, Spain

Copyright © 2025 Moldtech. All Rights Reserved