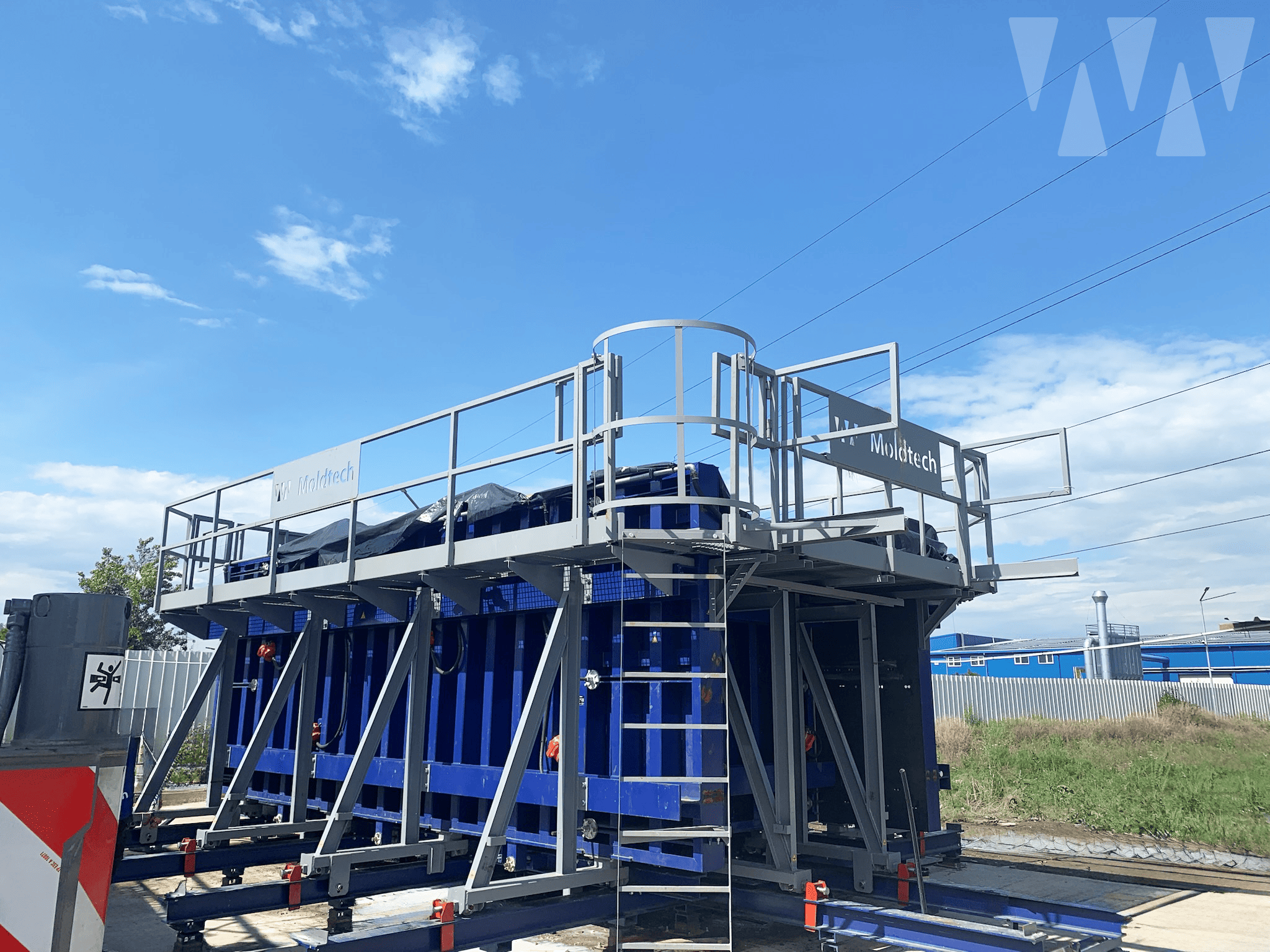

MOLDTECH STRENGTHENS ITS PRESENCE IN EASTERN EUROPE WITH A NEW 3D MOULD FOR TRANSFORMER SHEDS

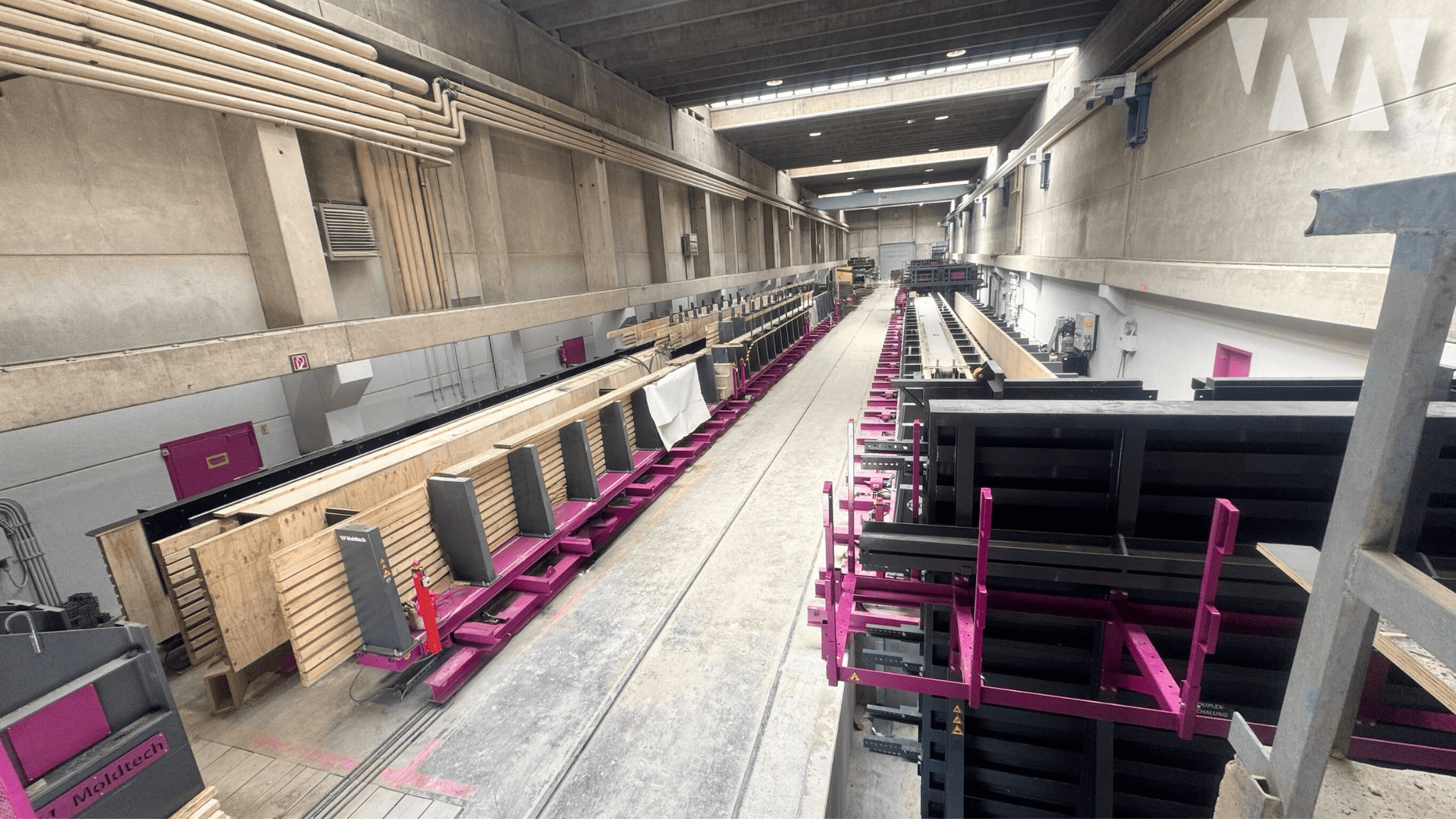

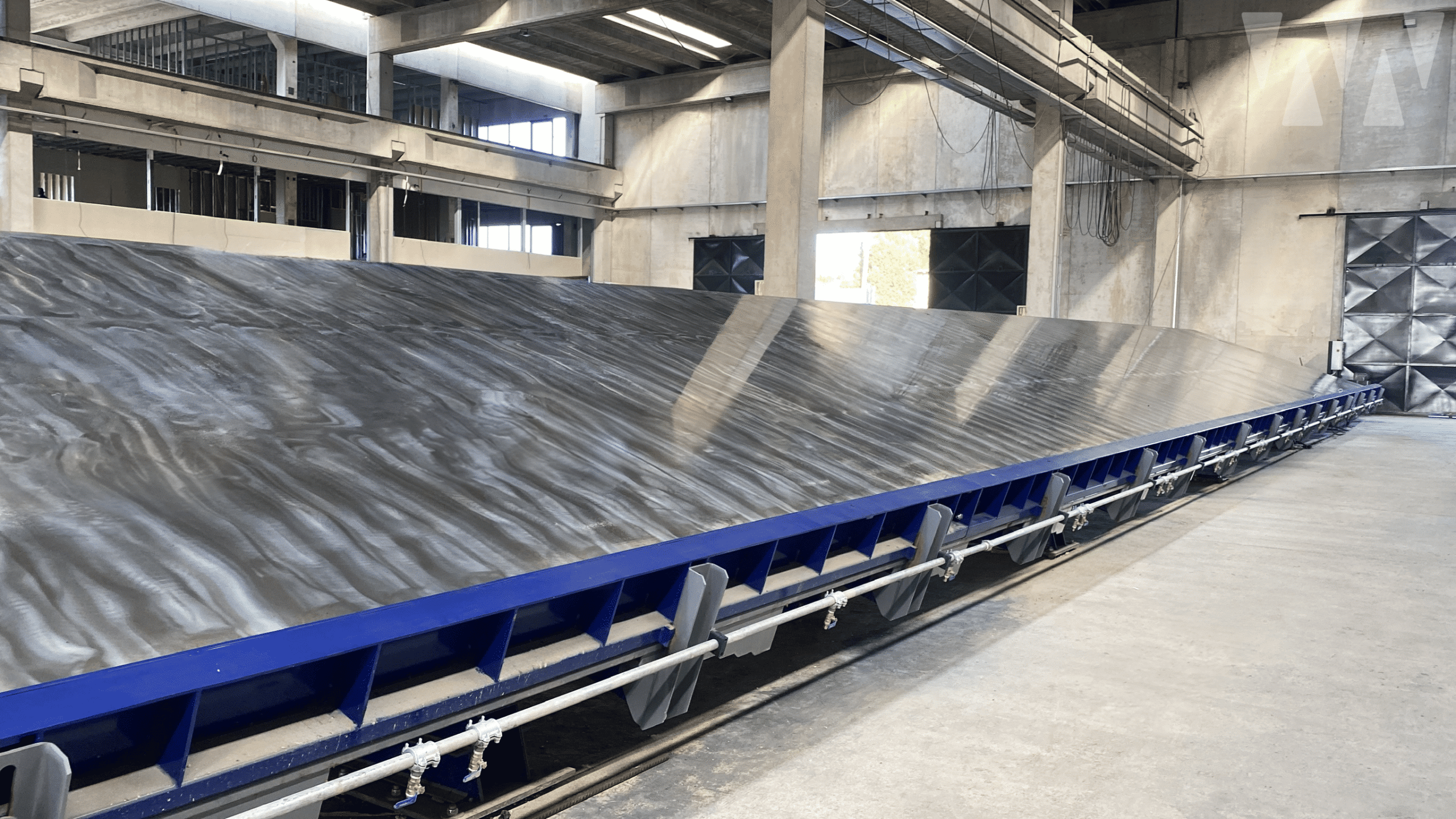

Moldtech has successfully completed the supply of a 3D mould for the production of precast concrete transformer sheds in Eastern Europe, consolidating the company’s presence in one of its most important strategic markets in the region. This mould, designed to manufacture single-piece, monobloc modules in non-prestressed concrete—including slabs and walls—responds to the client’s technical requirements […]