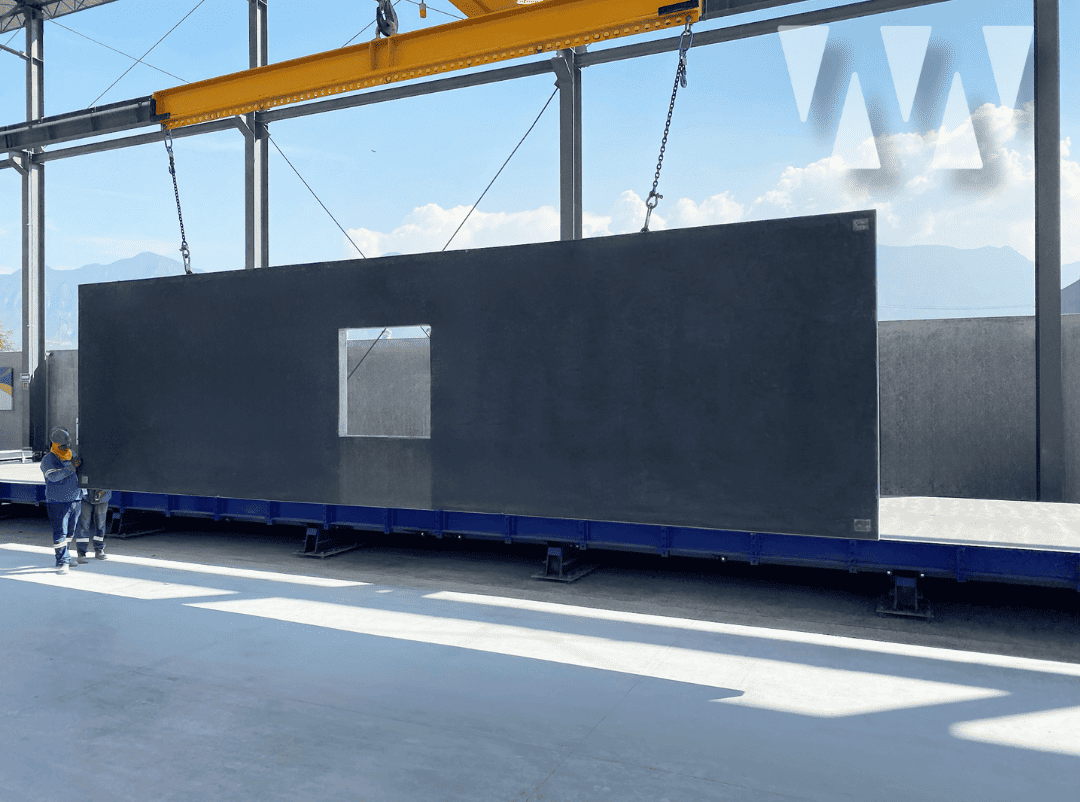

Hermanos Quijada and Moldtech drive the industrialization of residential facades through precast concrete

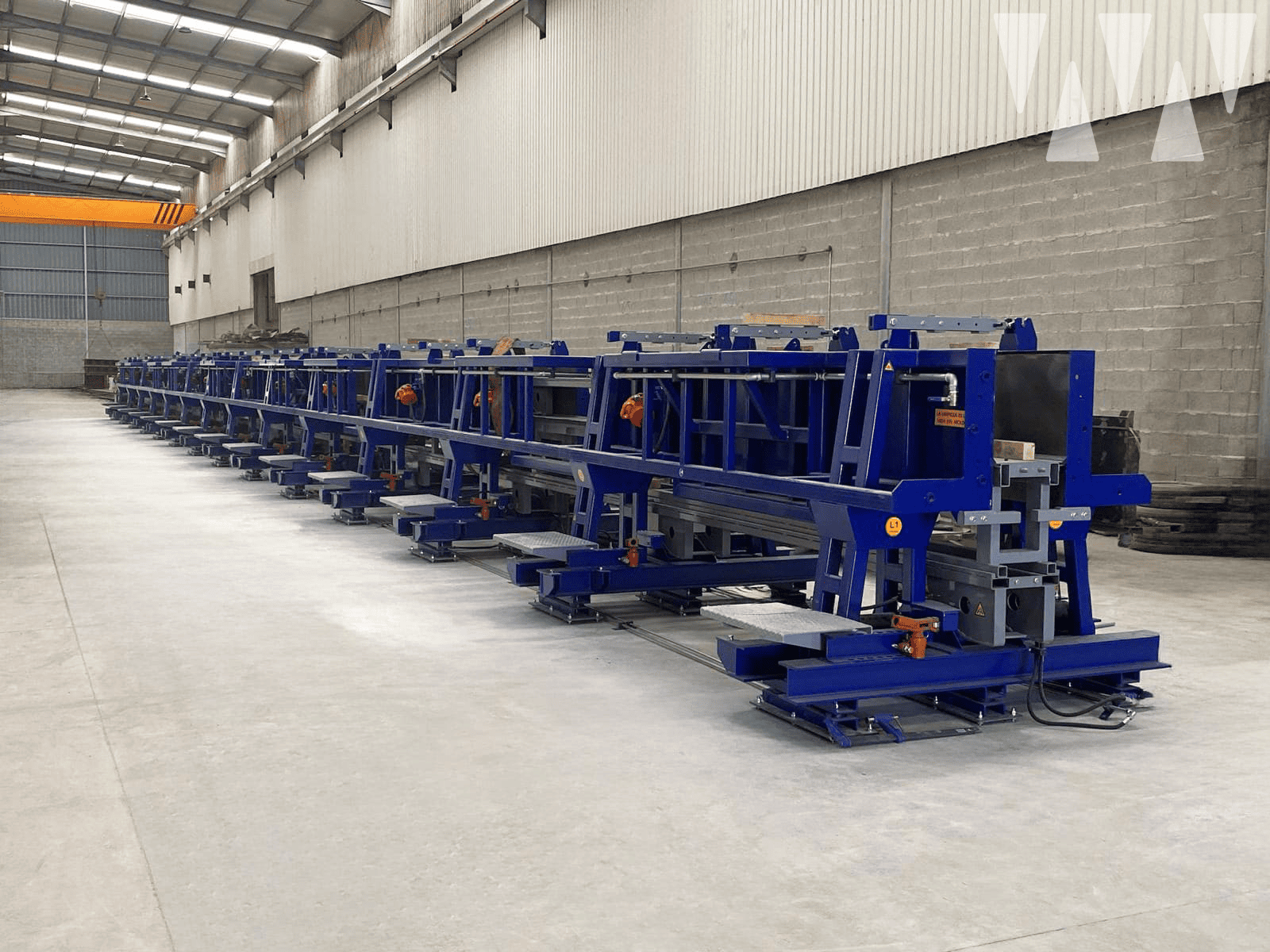

Residential construction in Spain is progressively moving toward more industrialized construction models, in which process control, final quality and reduced execution times are becoming key factors. Within this context, Hermanos Quijada has consolidated its position as one of the leading precast concrete manufacturers for residential façades in southern Spain, building on more than 20 years […]