Designed for the production of precast wetcast concrete frames and half-frames

Do you want more information?

Contact an expert from our team now

- +34 955 444 190

- info@moldtechsl.es

Designed for the production of precast wetcast concrete frames and half-frames

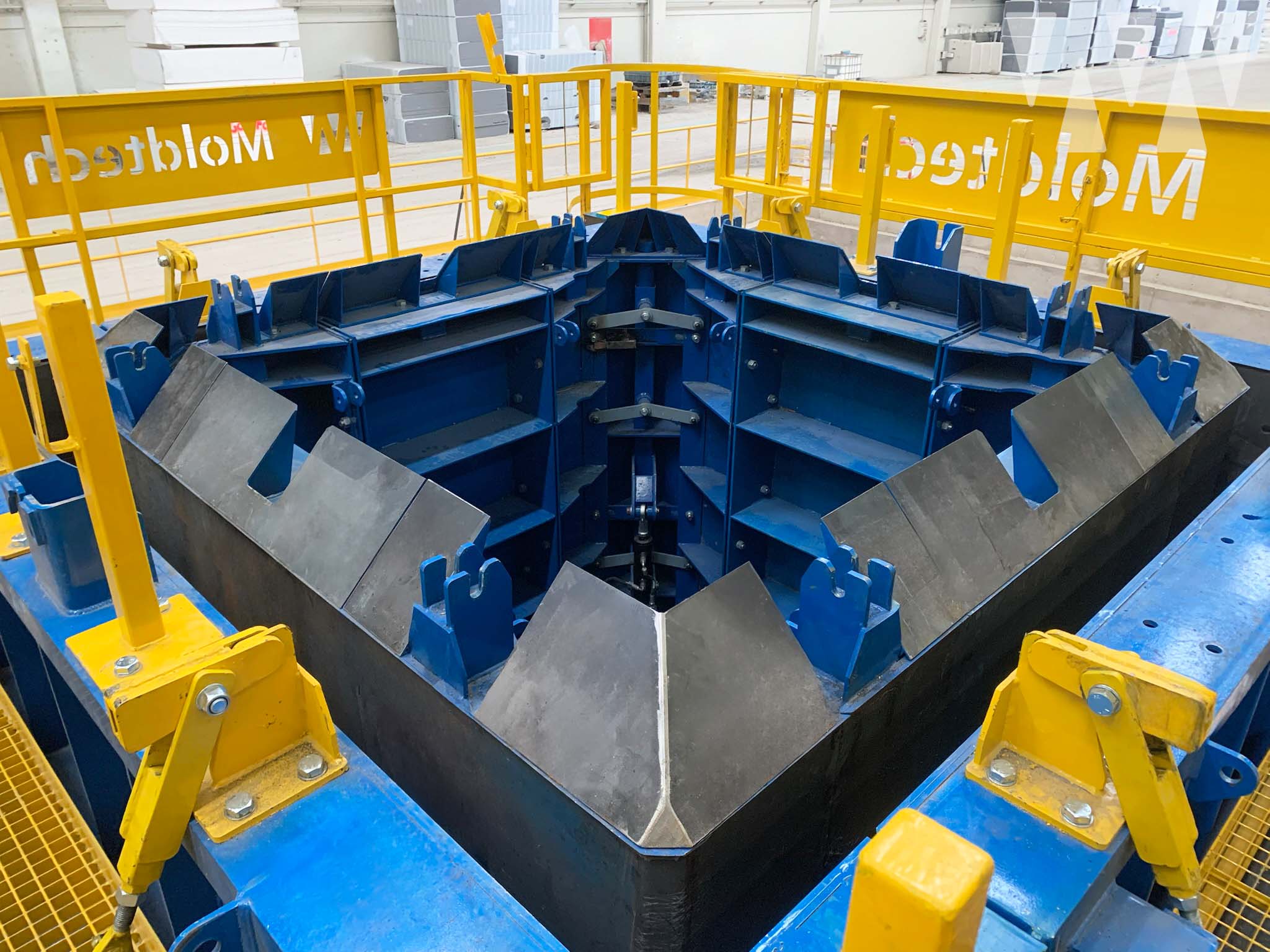

The modular mold for elevator shafts designed and manufactured by Moldtech is intended for the production of load-bearing reinforced precast concrete cores, conceived as the stabilizing structural element of the building and the main reference axis for the installation of slabs, structural panels or PPVC modules. The system enables the production of modular vertical segments ranging from 2.5 to 3.5 meters in height, which are assembled on site with total precision. During manufacturing, elevator guide rails, door openings, electrical conduits and anchoring points are integrated directly in the plant, delivering a fully finished element ready for immediate installation and significantly reducing work at height and overall construction time.

The mold features a versatile configuration through removable and bolted extensions, allowing the production of different dimensions and wall thicknesses of 160 mm and 200 mm, as well as telescopic supports for height adjustment according to project requirements. Its hydraulic opening and closing system ensures safe and precise demolding, while the integrated electric vibration system optimizes concrete compaction, improving surface finish and overall quality. The system provides high dimensional accuracy, excellent structural performance, reduced installation time — estimated between one and two days per core — and overall optimization of the construction process.