For the production of precast concrete columns with corbels on 4 sides.

Do you want more information?

Contact an expert from our team now

- +34 955 444 190

- info@moldtechsl.es

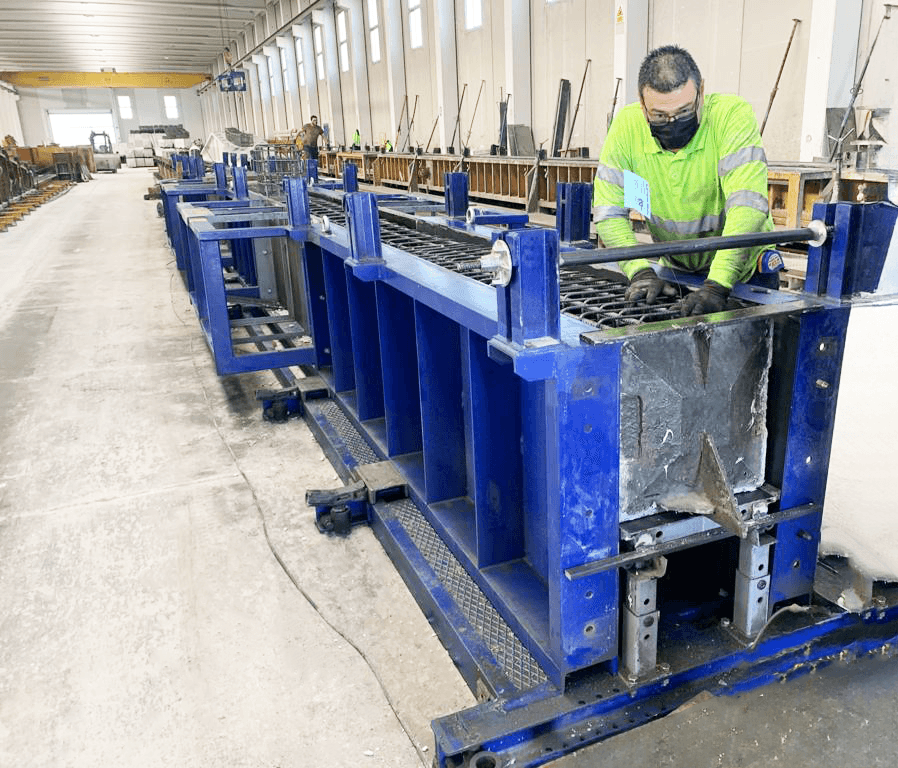

For the production of precast concrete columns with corbels on 4 sides.

Manual mould for columns produces precast concrete columns in a base-plate. The opening is normally done by overhead crane by means of one or both collapsible sides.

This mould enables the production of precast concrete columns with corbels on four sides, being possible to adjust the length of the pillar and the number and the position of the corbels. This feature gives to the mold the capability of undertaking the production of a large variety of small precast columns with a moderate investment.

The manual moulds for columns can be divided mainly in:

The mould is built with a support structure with transversal beams, on top of which two hinged mould sides can be fixed in different distance positions to adjust the columns width.

To make columns with a corbel at the bottom, it is necessary to make a pit, since the mould has no elevation. In case the client requires the mould can be elevated.

Under this system the Client would need different baseplates for each specific width. In addition, the baseplates can be positioned at different heights, thus, the mould can cast different sections. These different baseplates feature removable rubber chamfer assuring water tightness and preventing leakage.

The double (with 2 working lines) manual mould for columns is operated in the same way as the single mould. There are 2 configurations of the double mould:

With this configuration columns with corbels only on 3 sides can be produced.

The columns production can be accelerated in this mold by means of the application of vibration, which eliminates voids and improves the surface finish and the mechanical properties of the precast piece.

Another system to increase the productivity is the use of heating by steam or hot water, which increases the temperature of the concrete and accelerates hydration reaction of the cement limestone. To this effect, the mould can incorporate finned tubes and insulation tarpaulin.