Designed for the manufacturing of precast columns with two casting baseplates in parallel.

Do you want more information?

Contact an expert from our team now

- +34 955 444 190

- info@moldtechsl.es

Designed for the manufacturing of precast columns with two casting baseplates in parallel.

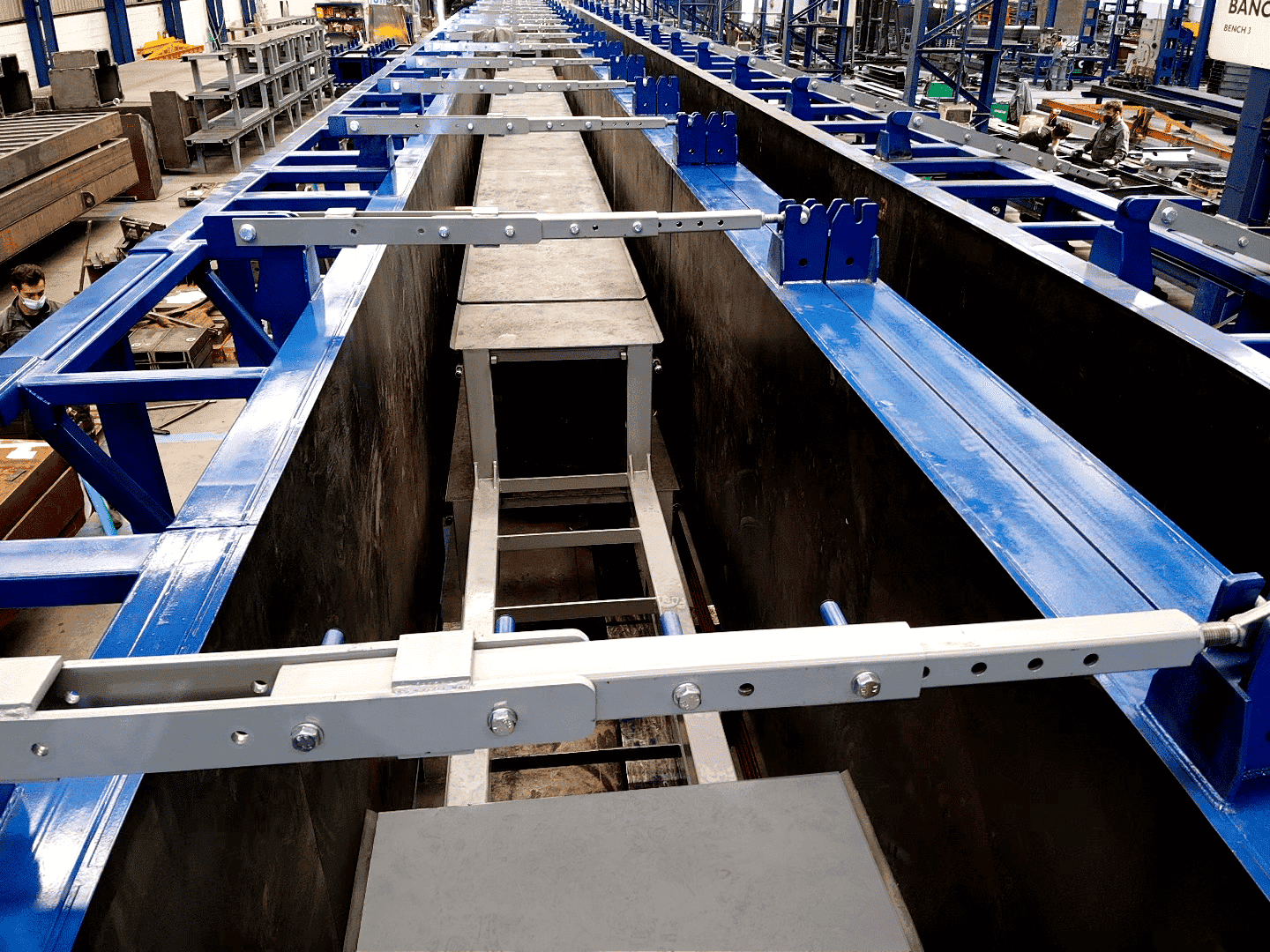

Double mould for columns produces precast columns with two casting baseplates in parallel with the capability of producing simultaneously two columns of different sections.

The most common version of this mold has two exterior sides and a central panel that is common for the two baseplates, allowing the production of columns with corbels on up to 3 faces. Another version of this mold has a double central panel, which allows the production of prefabricated columns with corbels on 4 sides.

Although the opening system of the mould may be mechanical, it is common to implement a hydraulic system with synchronized cylinders. These cylinders move the two bases and two vertical mould sides, while a third mould side remains fixed. This allows removing easily the precast columns.

With the mould opened, it is possible to remove the bases and put others with a different width, or even adjust the bases in height, when they are supplied with the suitable support. A more advanced option is the hydraulic adjustment in height of the bases. This allows the production of precast columns with different sections on the same machine.

As in the case of other moulds, it is possible to assemble several stretches in series in order to increase the production capacity, separating the columns with appropriate stoppers.

A usual system for the corbel production in these moulds is the composed by the corbel formworks and the boxes in where these formworks are installed. That allows a range of variation for the position and even the replacement of the corbel formworks for straight formworks to suppress the corbels.

As a complementary function, it is usual to incorporate to these moulds a vibration system with electric or pneumatic activation, which allows improving the surface finish of the precast columns as well as compacting the concrete when it is formulated with less water.

Another productivity improvement is that may be implemented by means of a heating system. For that purpose, a finned pipe circuit is integrated into the various elements of the mold for leading hot water or steam.