Used mainly in industrial buildings and public works.

Do you want more information?

Contact an expert from our team now

- +34 955 444 190

- info@moldtechsl.es

Used mainly in industrial buildings and public works.

At Moldtech we have extensive experience in infrastructure projects around the world, including projects for the construction of bridges, highways or viaducts. See the following example: MOBILE FACTORY FOR ROADS AND BRIDGES.

Our high capacity to adapt our services and equipment to the construction and engineering needs of each client stands out.

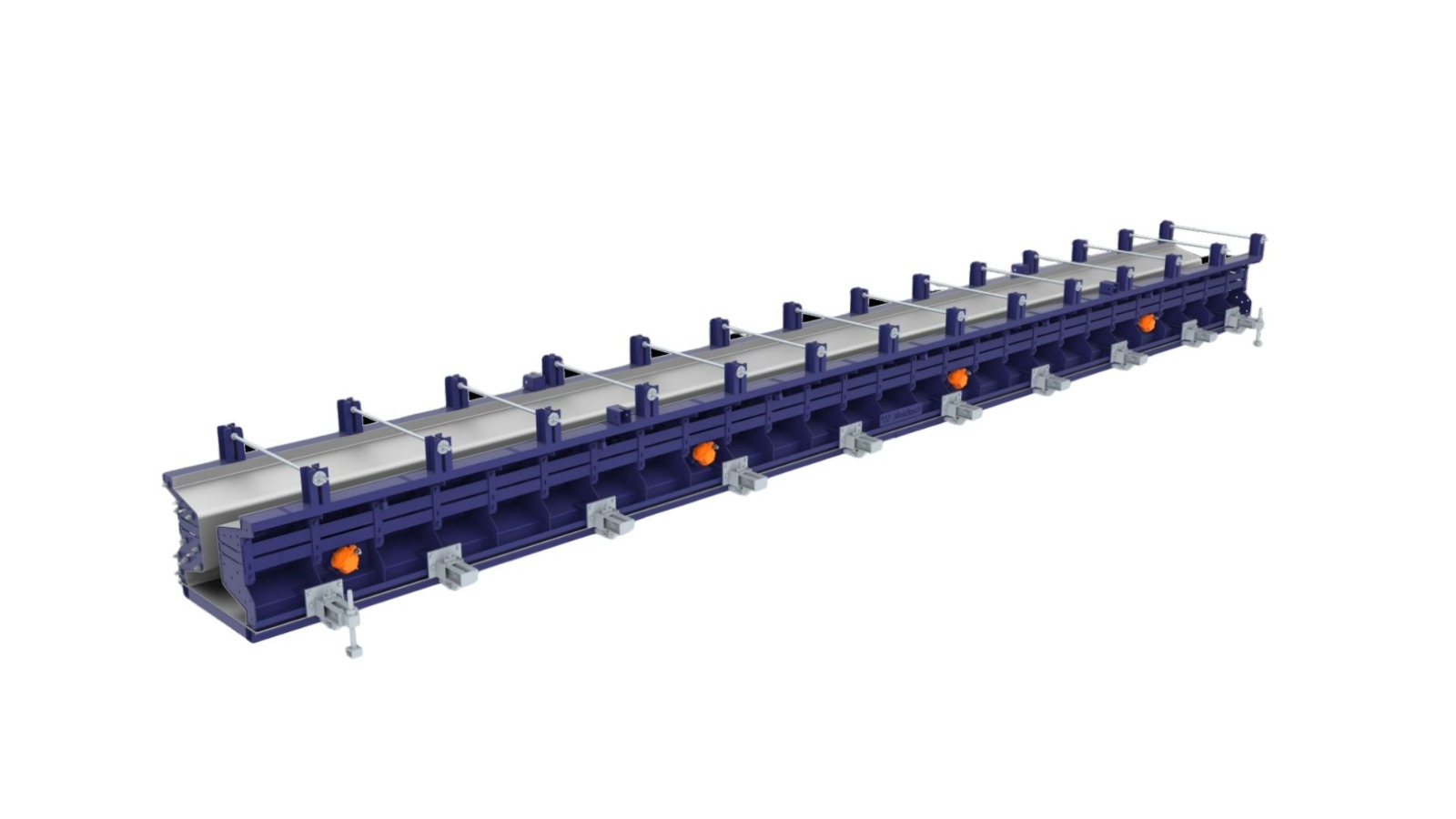

The mold to produce bridge beams is composed of a base (universal casting bed system, an existing concrete slab or other type of bottom) and two I-shaped side molds with a quick fixing system with different positions for adjusting the size of the bridge. beam to produce

The universal casting bed system provides the base on which different precast elements can be cast using molds that are placed along the track.

The structure is anchored to the ground and the sides of the mold are placed on top with an adjustable system to regulate the width of the track through a single base plate.

These side molds have manual or hydraulic opening/closing and are prepared to be placed on the support structure and fixed to the lower base plate by means of a quick locking system with different positions for size adjustment. The mold also has a superior quick release system to guarantee maximum rigidity.

These side molds are built with modular height adjustment to manufacture parts of different heights. The length of the pieces can be varied by placing the tapes.

The system can also be expanded by acquiring structure extensions, base plates and modular side molds to manufacture different reinforced or prestressed elements.

These side molds also have a pneumatic vibration system to help compact the concrete. Said pneumatic vibration system would be made up of independent action VSP vibrators, with a circuit of pipes and accessories, as well as a manifold to connect to the customer’s compressor.

We also offer a heating system that increases productivity by reducing waiting time. This system consists of finned tubes placed along the sides of the mould.

COMPLEMENTARY EQUIPMENT

The essential accessories for this type of mold for the production of prestressed beams are the hydraulic control units and the tensioning lances, the relaxation heads for the slackening.

If you wish to obtain more information about the characteristics of this equipment, do not hesitate to contact us.