For the manufacturing of concrete slabs.

Do you want more information?

Contact an expert from our team now

- +34 955 444 190

- info@moldtechsl.es

For the manufacturing of concrete slabs.

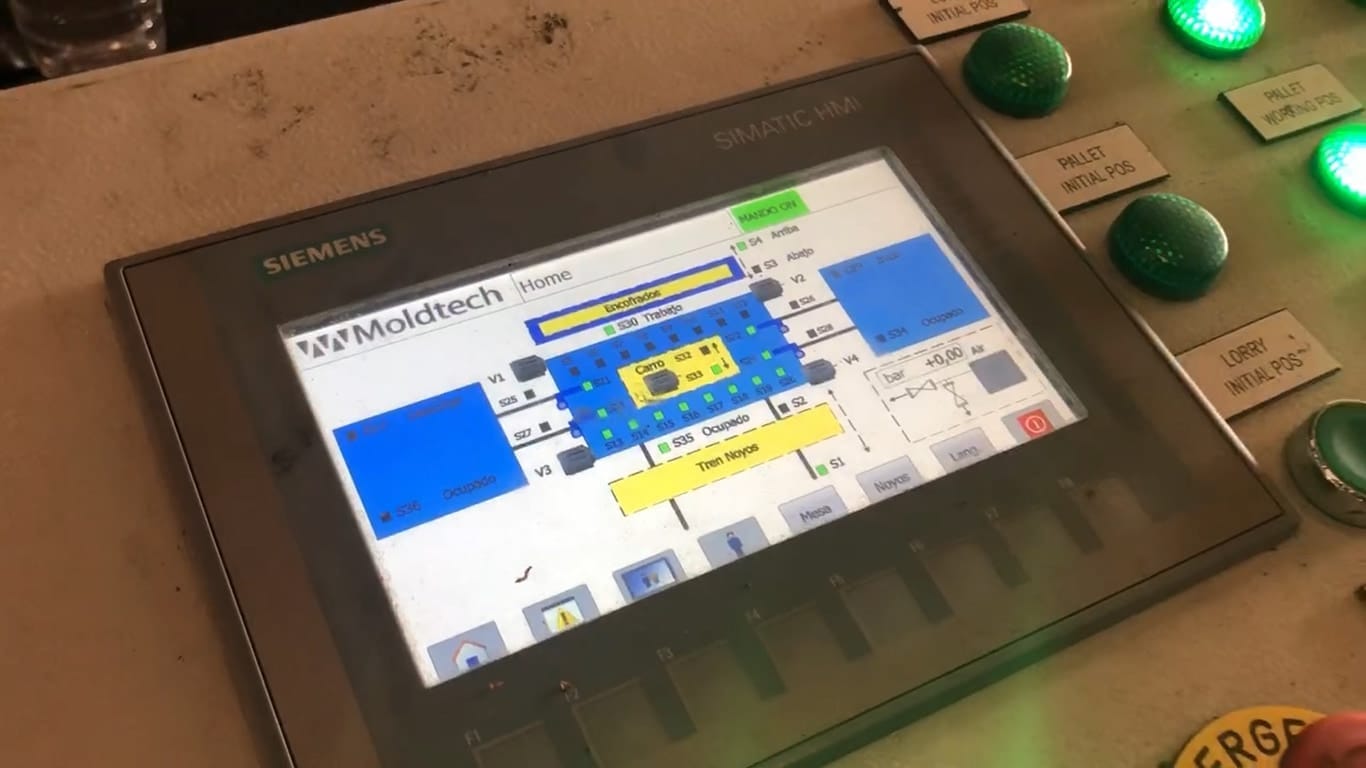

It is a fully automated circulation system for the production of slabs and walls with concrete double layer and interior space. By dividing the entire manufacturing process into independent work phases, the pallets move automatically between these phases to achieve optimal organization in manufacturing.

The stations are divided into different areas:

Cleaning and oiling station: The pallets are cleaned after the previous finished element has been removed and the surface is oiled.

Plotting: Once cleaned the pallets are placed in the plotting station where a plotter on a support structure is programmed to transfer the design of the panels to mark the places where the shutters have to be placed.

Preparation and shuttering zone: in these stations the shutters, lifting elements, inserts and any other elements are placed. Buffers are independent of the circulation lines, allowing longer stay of pallets without blocking the lines.

Reinforcement zone: in these stations the reinforcement is placed.

Transfer Wagon: in the middle of the circulation line the wagon features a pair of sideways shifters that move the pallets transversally to stations and buffers and across the different circulation lines moving in opposite ways, allowing for great flexibility.

Laser projection: Using laser technology the different measurements and dimensions of the precast elements are projected on the casting pallet to check all elements have been placed with accuracy before casting.

Concrete spreading and vibration: here the concrete is poured on the pallet with an automatic concrete distributor and then vibrated with an electric vibration installation.

Pallet lifter and curing chambers: with an automatic pallet lifter mounted on support structure that grabs the pallet from above to lift them and introduces the pallet for curing and retrieve them for demoulding once the concrete is set.

Flipping station for double walls: with a turning device mounted on support structure, the pallets are secured on the frame and lifted to be stacked for curing and turned 180º to cast the second layer of the double walls.

Tilting: here the pallets are hydraulically fastened to a tilting frame to tilt the pallet some 85º for stripping the finished panels.

The quantity of stations depends on the productivity one may need.