Boosting precast construction in Romania, our company, Moldtech, has closed a new contract with a prominent company in the construction sector in Romania.

The Romanian company, whose main focus is providing comprehensive services in the construction field, has acquired a diverse range of equipment supplied by Moldtech. Both companies share a philosophy of treating each project as unique, offering “turnkey” solutions tailored to the specific needs of their clients.

The supply includes equipment designed to optimize the precast construction process. Among them, a hydraulic mold for columns stands out, which speeds up and improves the production of essential structural elements. In addition, a mold for box culverts or pocket foundation was delivered along with two bases, a 2m³ concrete skip and a 12 m x 4 m tilting table. This equipment not only improve production performance, but also ensure quality and precision in every phase of the process.

Mold for precast concrete pocket foundation, it is a modular system of steel formwork designed for the production of precast pieces with a square or rectangular shape that serves as a support base for fixing columns in an industrial building. This mold is used also for the manufacture of box culverts or half-frames, allowing the client versatility for the manufacture of different pieces.

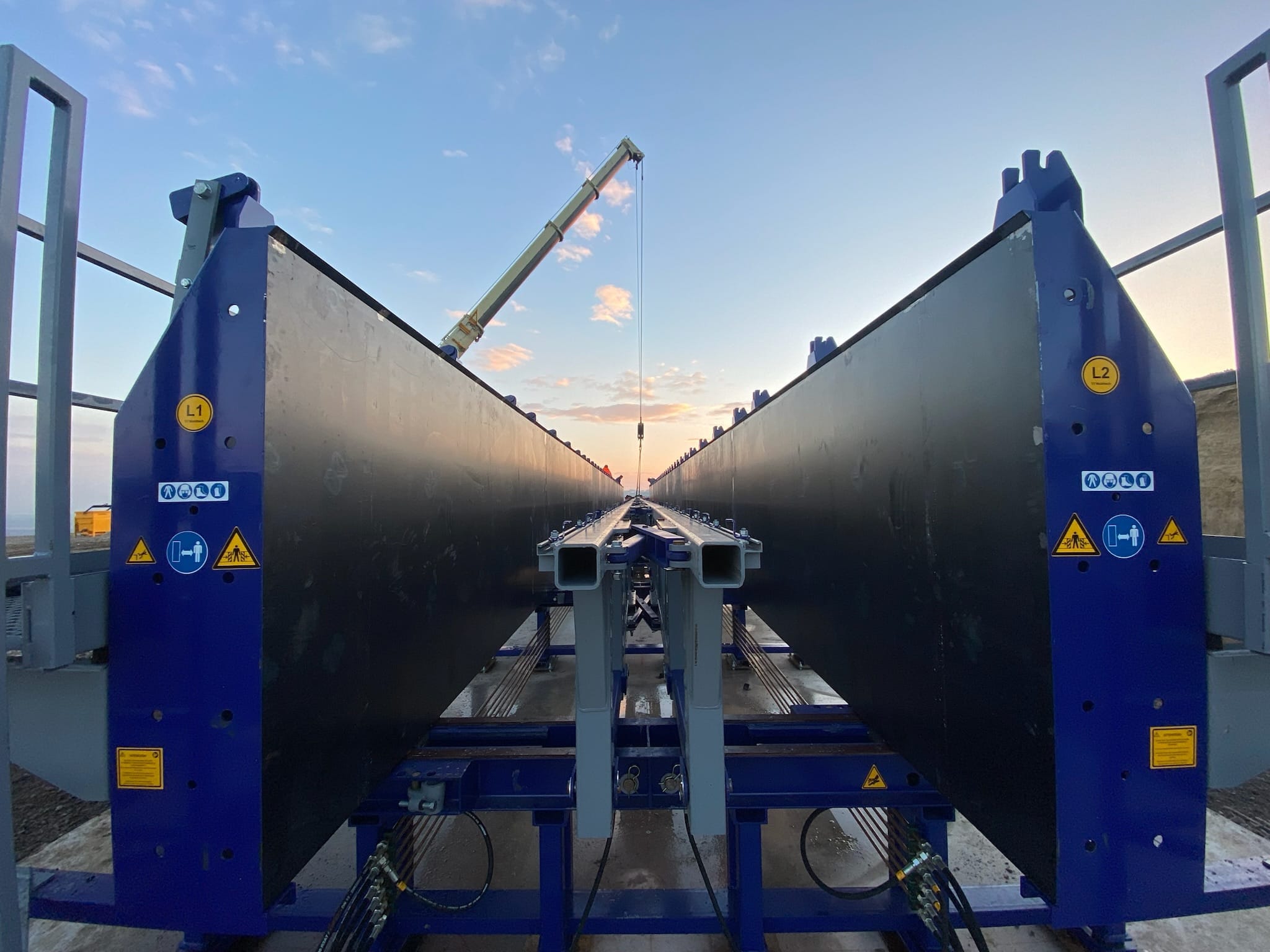

Hydraulic mold for columns and beams, with a length of 33 m, for the production of columns with a variable section from 500X500 mm to 1200×1200 mm. The mold features bottom support for different bottom dimensions, stoppers and removable corbel holders for changing the section of the column to be manufactured. The mold has a hydraulic power unit to perform opening, closing maneuvers.

2m³ concrete skip or bucket, designed for concrete distribution. The machine incorporates a hydraulic power unit to operate the opening-closing mechanism of the concrete pouring gate using a control button.

Tilting table, Moldtech tilting tables are designed to produce precast concrete panels in various thicknesses for residential, commercial and industrial construction. Its tilting mechanism allows the panels to be easily removed in the vertical position with less time for the concrete to harden.

Investment in precast construction technology is a clear indicator of Romania’s progressive vision to boost its infrastructural development. With ongoing projects ranging from improving roads to modernizing rail systems, demand for efficient and sustainable solutions in construction is increasing.

Recognized for its expertise and commitment to innovation, Moldtech is poised to play a pivotal role in the Romanian construction landscape. The company not only supplies high-quality equipment, but also offers specialized technical advice to ensure the effective implementation of its solutions.

This strategic step not only benefits both companies involved, but also contributes to the overall progress of the construction sector in Romania. The collaboration between Moldtech and the Romanian company is a testament to the growing importance of precast construction and the shared commitment of both parties to offer advanced solutions that drive the country’s sustainable development.