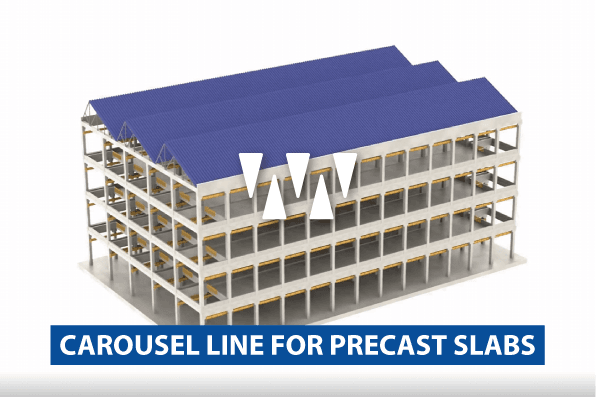

COMPLETE LINE FOR THE MANUFACTURE OF ELECTRICAL TRANSFORMER SUBSTATION

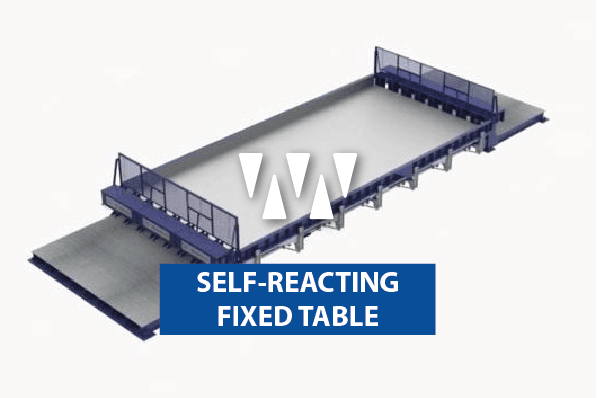

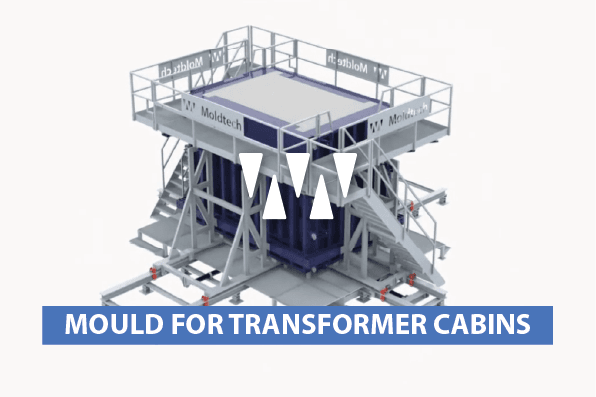

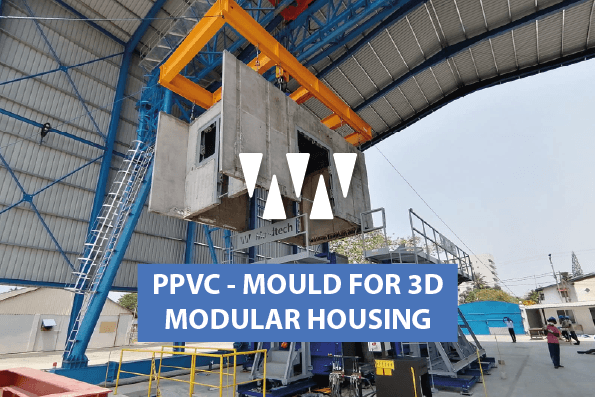

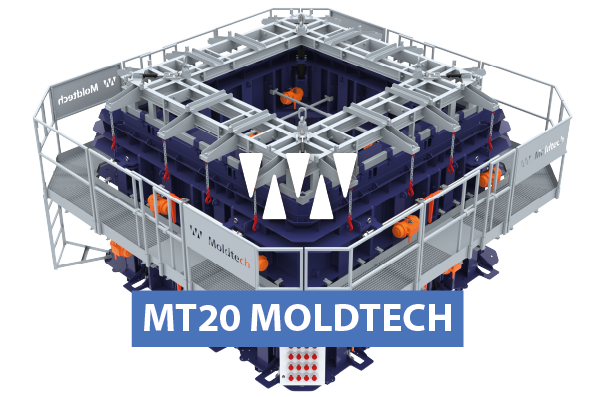

Moldtech presents a complete production line for the manufacture of reinforced concrete transformer substations in France, showcasing modular technology and tailor-made precast solutions designed for the European market. This automated plant integrates 3D moulds, fixed tables, hydraulic turning systems, and a carousel assembly line, enabling continuous, safe, and high-precision production of transformer substations. The project […]

COMPLETE LINE FOR THE MANUFACTURE OF ELECTRICAL TRANSFORMER SUBSTATION Read More »