Moldtech supplied a hydraulic double mould for columns, a tilting table and other ancillary equipment to Iasi, Romania.

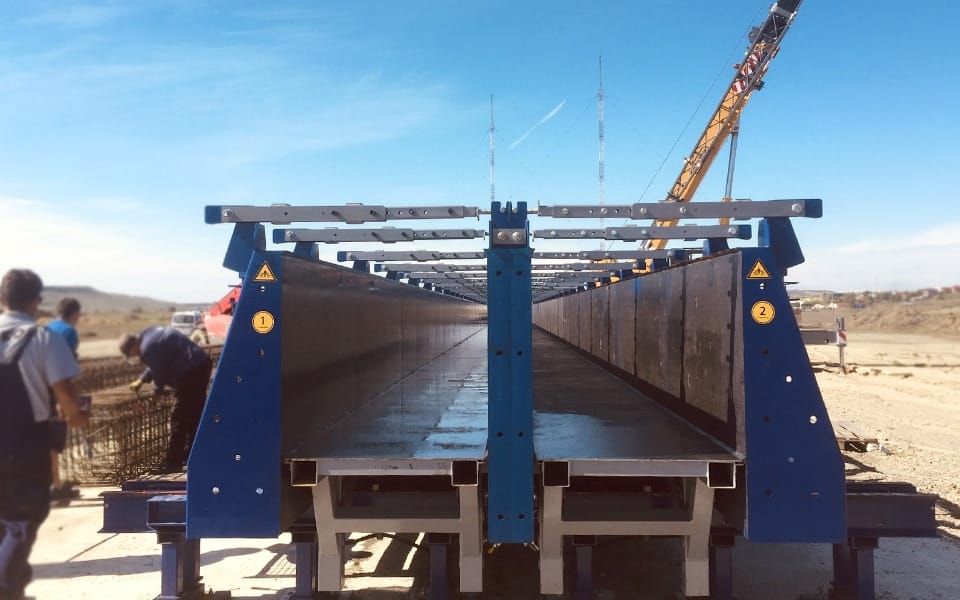

- Double hydraulic mould for columns of 33 m length, for the production of columns with variable section from 500 x 500 mm to 1000 x 1000 mm. The mould allows the corbels integration on 3 faces of each work line, as well as stoppers along the whole mould length. In addition, it features an electric vibration system. The mould has a hydraulic power station to carry out the opening and closing manoeuvres of the vertical mould sides hydraulically.

- Tilting table 12 m long and 4 m wide. The table is tilted by means of telescopic hydraulic cylinders, allowing a maximum tilt of 80°. Additionally, it incorporates a hydraulic power unit and an electric control panel to control the tilting operations of the table, an electric vibration system and, lastly, the longitudinal magnetic formwork for variation in height of the panels to be manufactured.

- 2 m3 concrete skip designed for the correct distribution of the concrete. This concrete skip features a hydraulic unit to activate the opening-closing mechanism of the discharge gate.