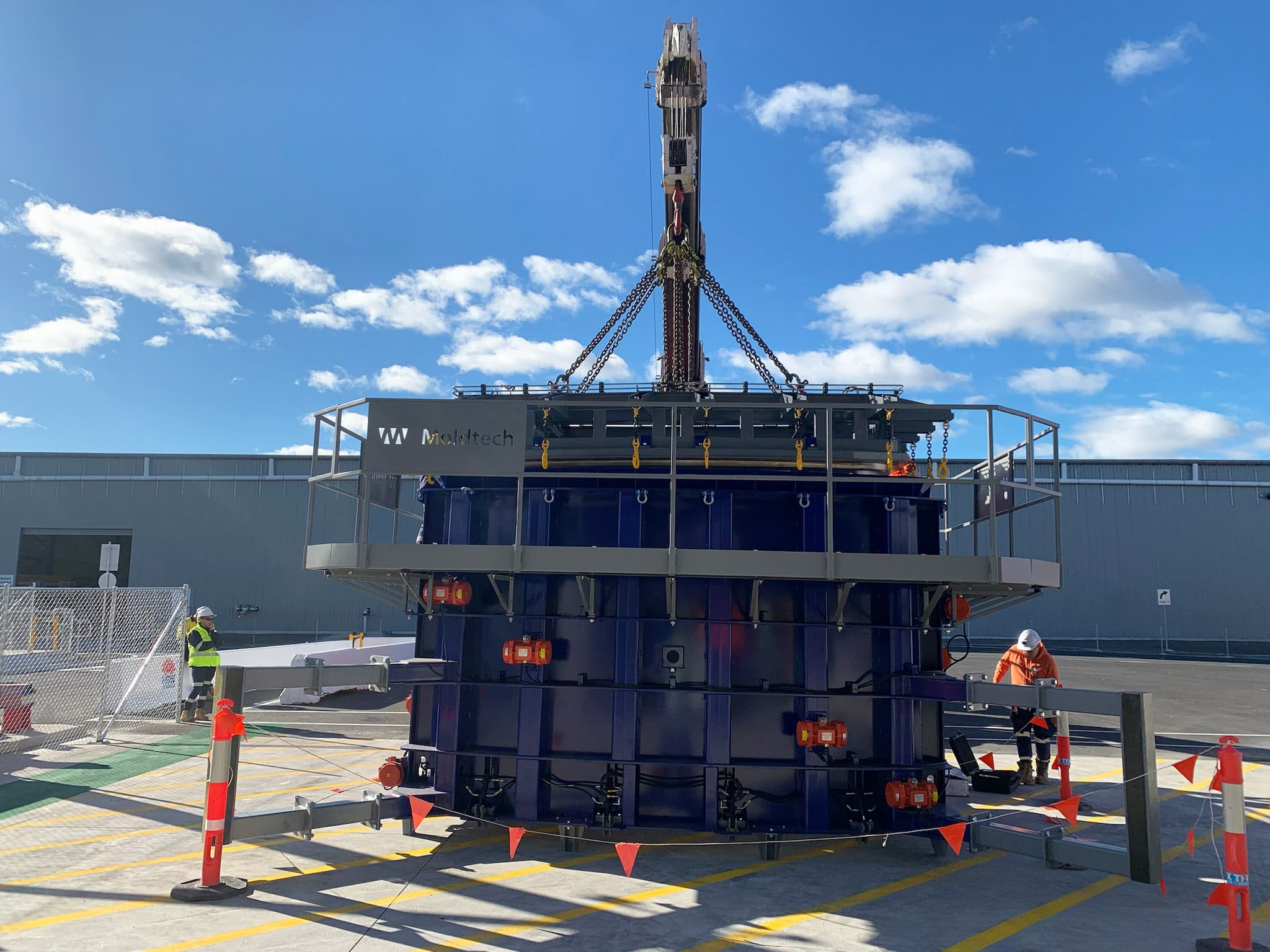

Moldtech has completed a new supply in Australia for a civil engineering project, reaffirming its international presence in the precast concrete sector. The solution includes an MT20 and a 90º – 30 T turner, both designed to optimise the manufacture and handling of parts for large-scale civil infrastructure projects.

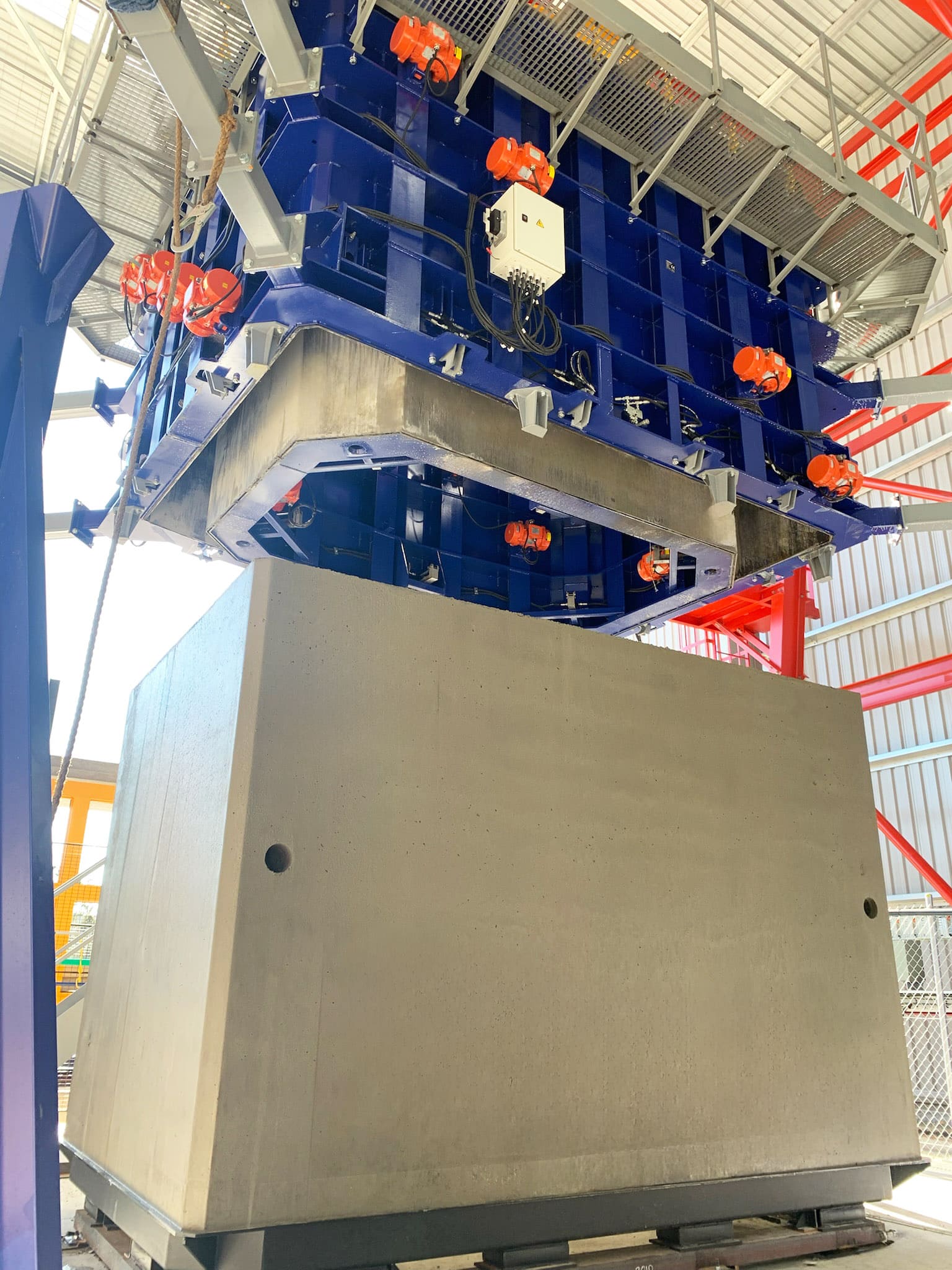

The MT20 is designed for the continuous production of non-prestressed precast concrete elements, with variable height and fully adapted to the customer’s technical requirements. Its main features include:

- Mould dimensions: L=3.7 m; W=2.4 m; H=2.4–1.7 m

- Electric vibration system managed by a vibration carriage

- Moulding and demoulding functions performed by hydraulic cylinders connected to a hydraulic power unit and a main control cabinet

As a complement, the project includes the supply of a 90º turner – 30 T, designed to turn precast elements from the moulding position to their final position on site. The equipment operates with a hydraulic system consisting of double-acting cylinders and a hydraulic power unit, controlled by a central panel.

This new project in Australia highlights Moldtech‘s ability to develop tailor-made engineering solutions that contribute to the modernisation of international civil engineering, offering reliable equipment that meets the highest quality standards.