PROY22-041

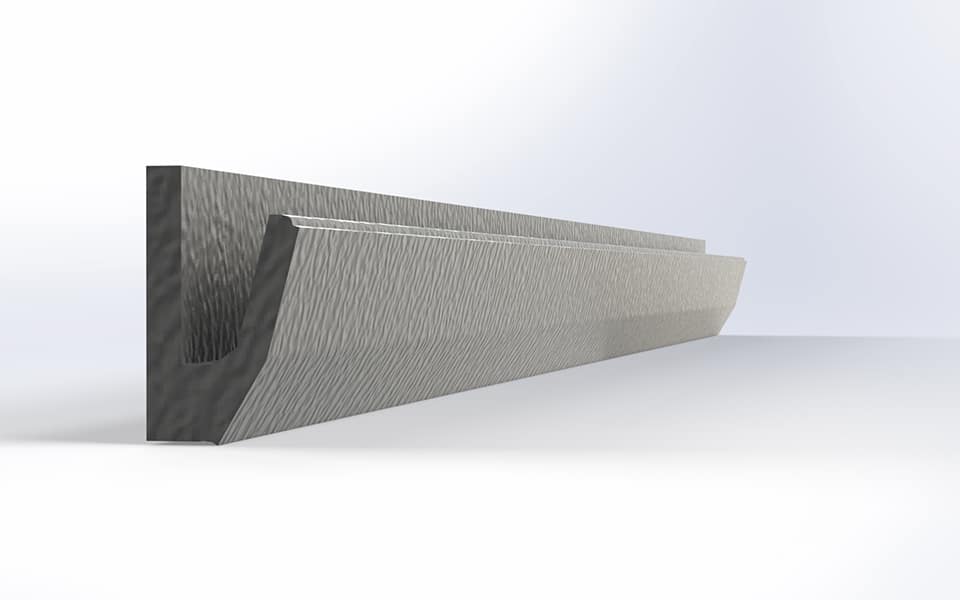

A planter mould is supplied, designed for the manufacture of non-prestressed precast concrete parts. The façade planter mould consists of a fixed central core, a fixed side and a hinged hinged side that facilitates the demoulding of the parts to be manufactured.

The mould consists of two 13-metre sections, which together form a 26-metre production line for the manufacture of different types of architectural concrete planters and 8 cover moulds.

Cutters are supplied which allow the length of the pieces to be adjusted, as well as the angle of the outer faces of the manufactured piece.

The clamping of the cutters is carried out by means of a magnet system. The magnet holders consist of a solid U-profile with integrated magnet fixing system and screw connections for fixing. The magnet holders are supplied with the disconnecting tool.