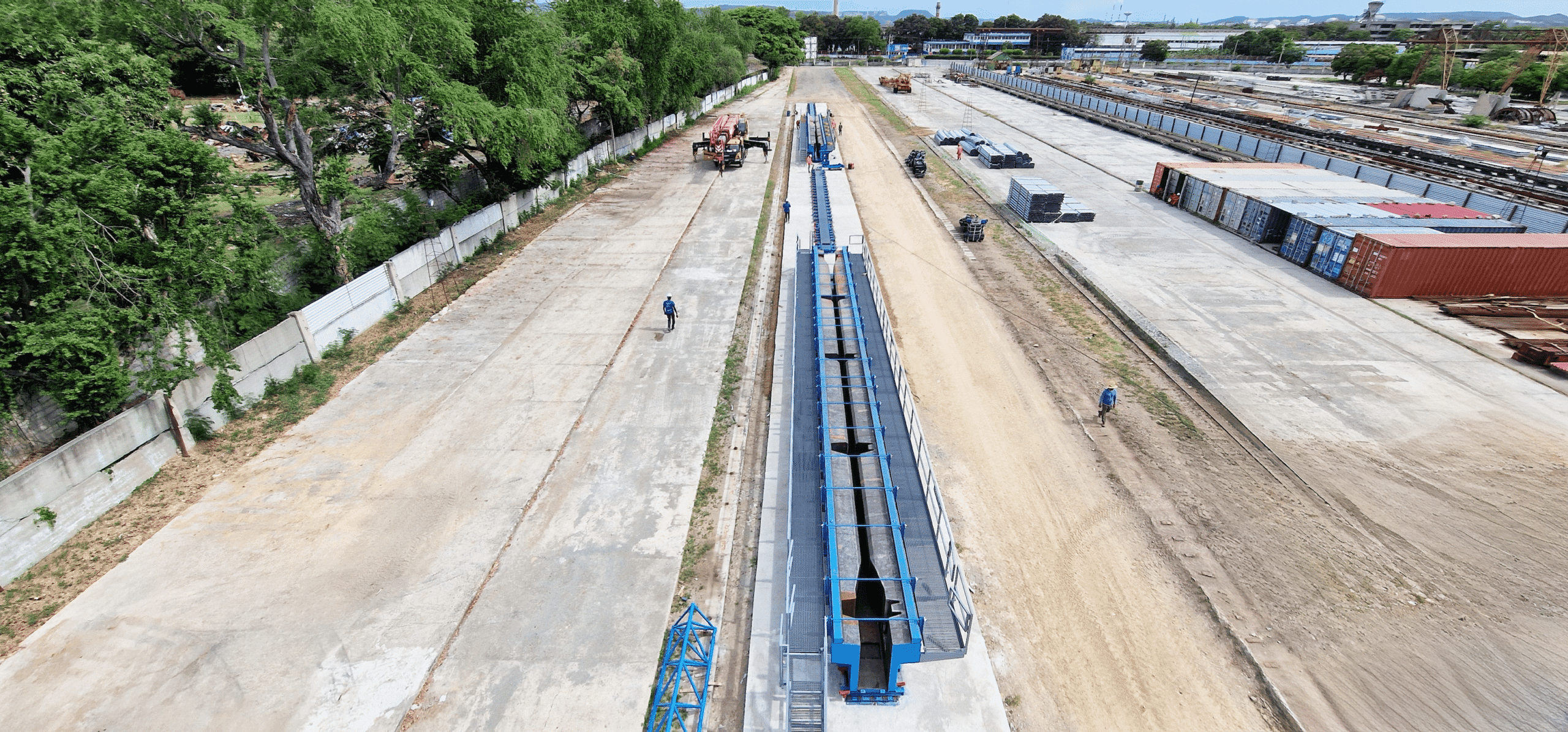

Moldtech has completed a new international order for the Caribbean, where we have developed a mould for post-tensioned precast beams up to 25 metres long and 1.6 metres high.

This equipment has been designed to produce beams 25 or 20 metres long, adapting to two different cross-sections, which offers the customer greater versatility in their structural projects.

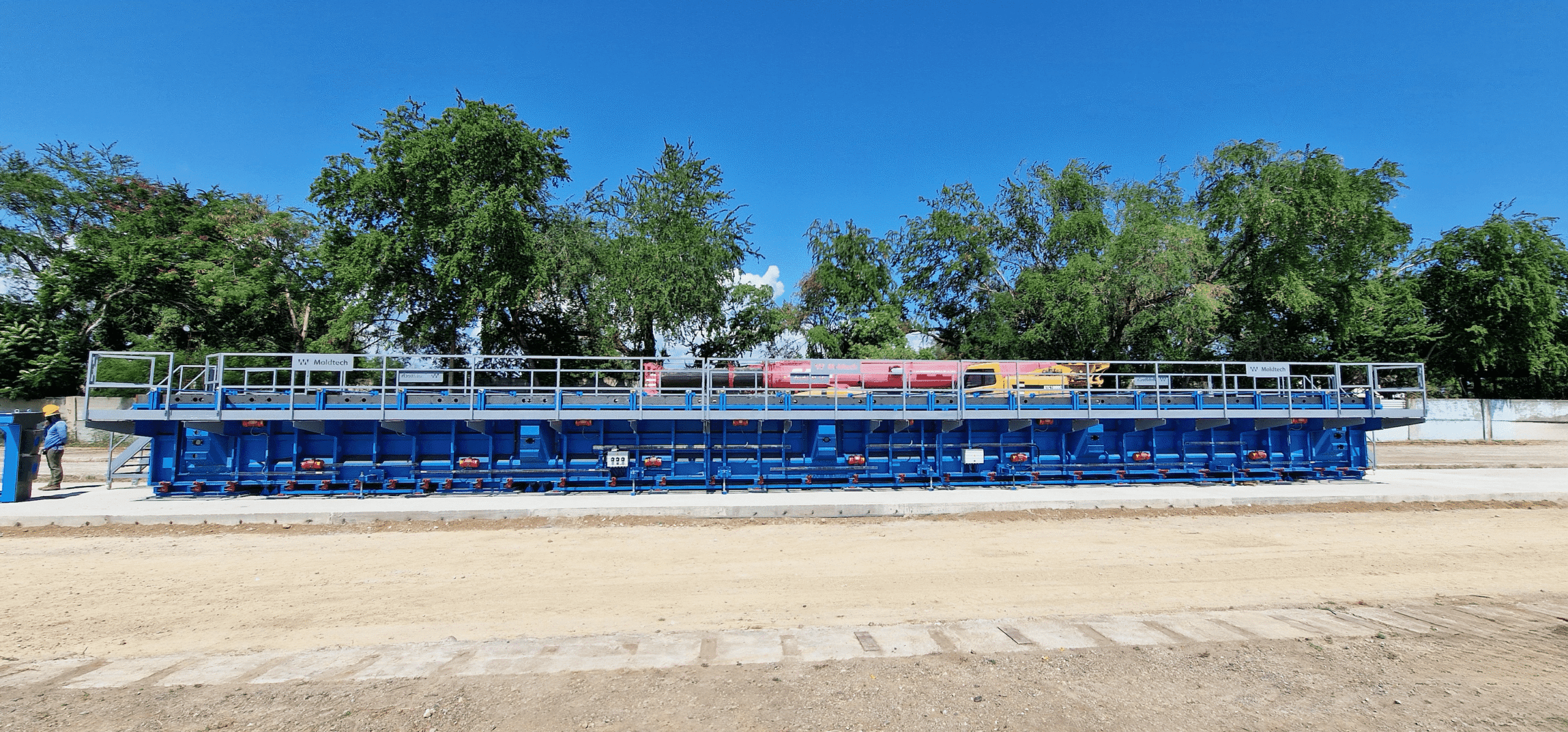

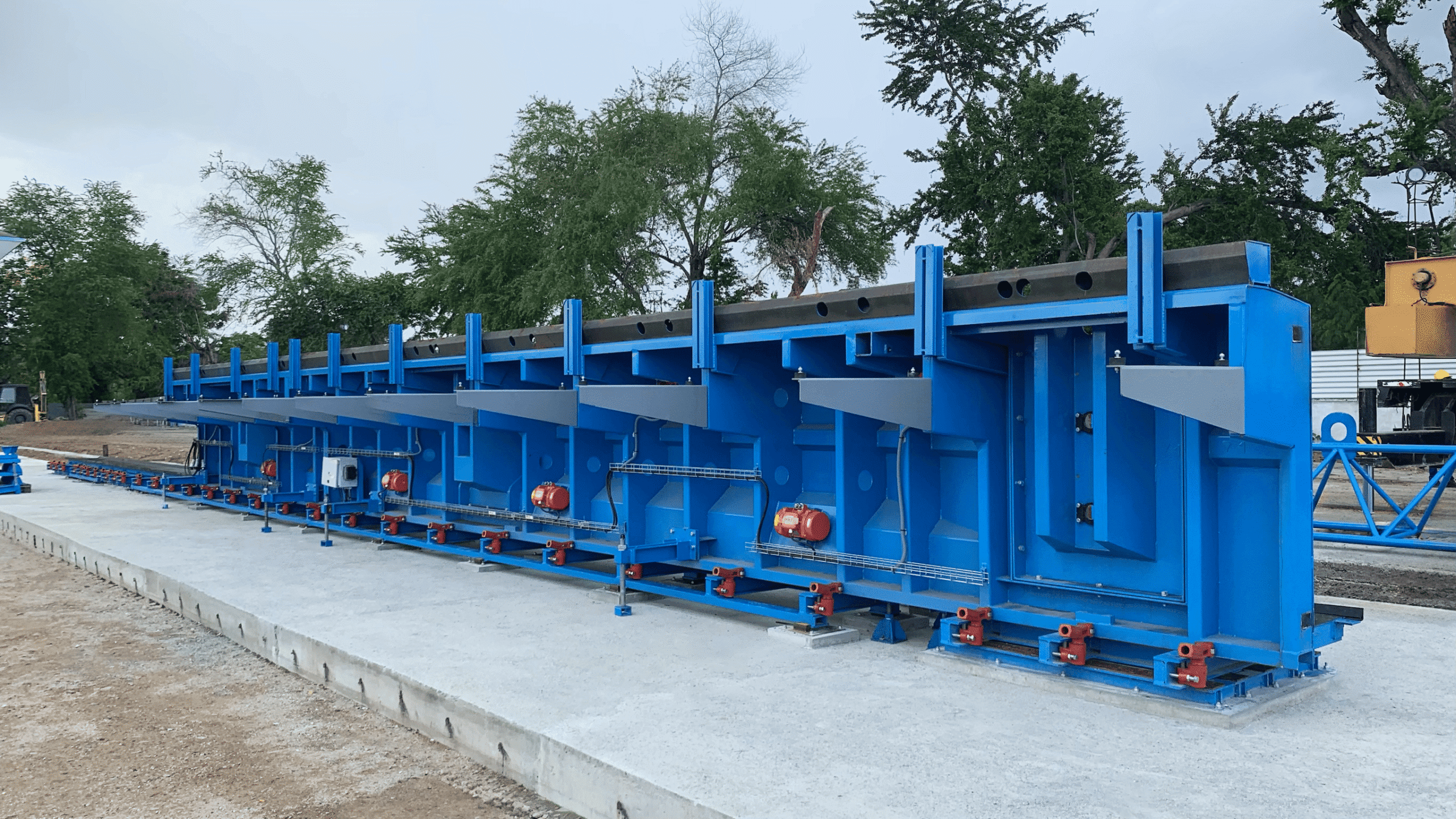

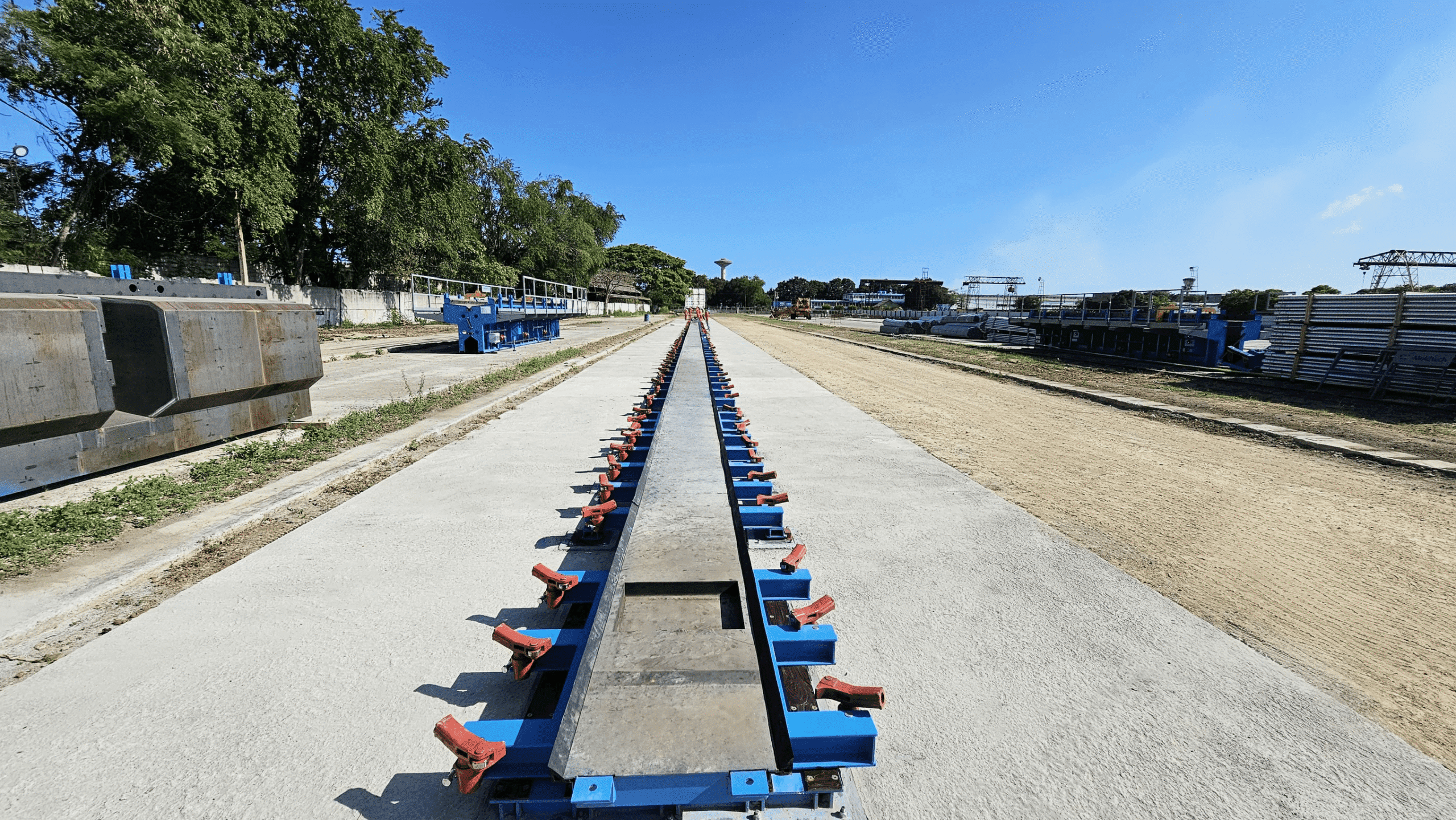

The mould consists of two side panels, two tie beams, a bottom panel and a bottom panel holder, which when assembled form the final volume of the beam to be prefabricated. It also incorporates an electric vibration system that ensures proper concrete compaction and a high-quality finish.

???? Scope of supply:

- Set of side panels for prefabricated beams

- Base plate L=25 m

- Bottom plates L=25 m, W=0.65 m

- Slab formers

- Electric vibration system

This new project once again reflects Moldtech‘s ability to offer customised, highly engineered solutions tailored to the specific needs of each customer and construction environment.

Manufactured in Spain. Building the future in the Caribbean.