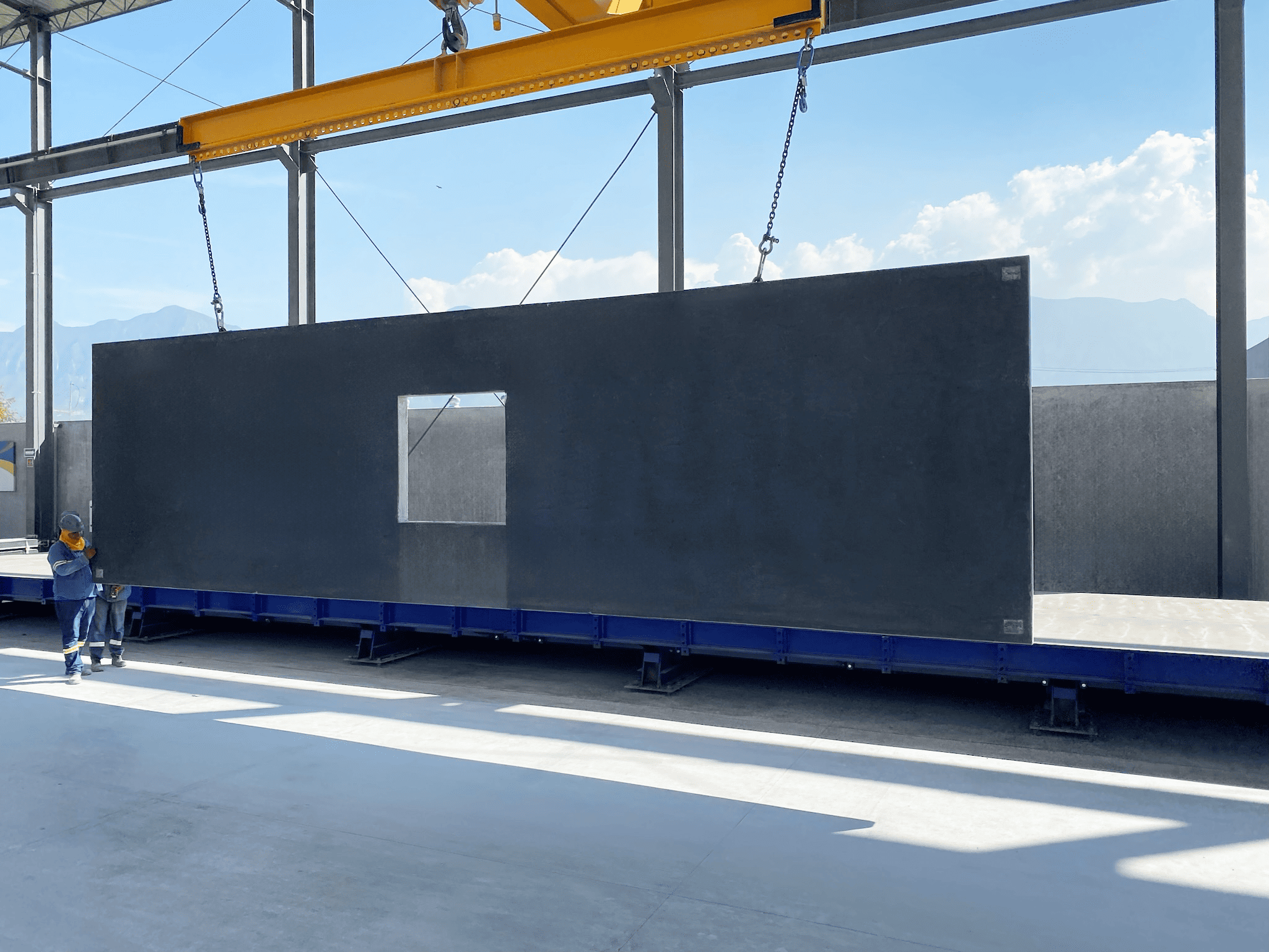

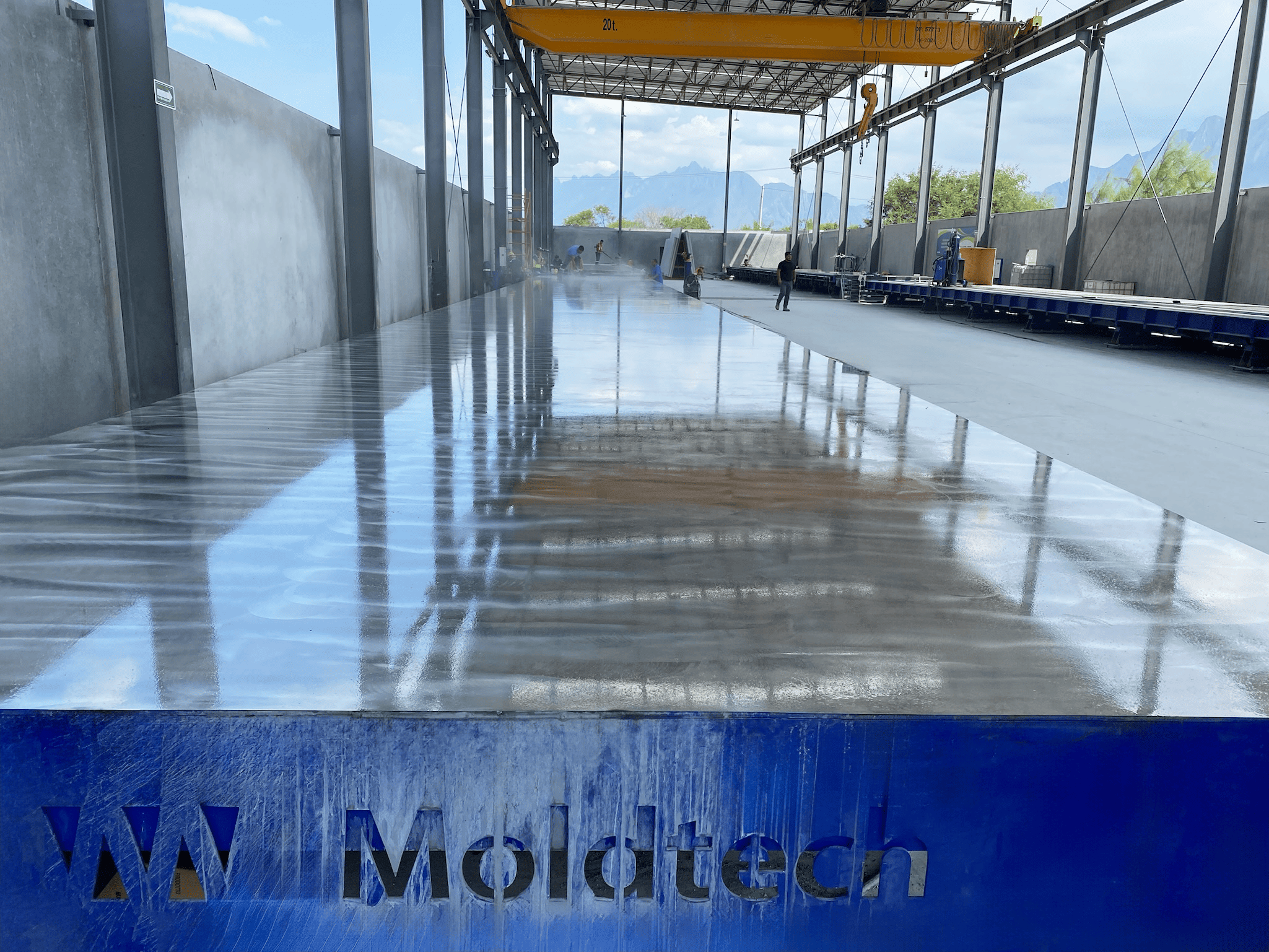

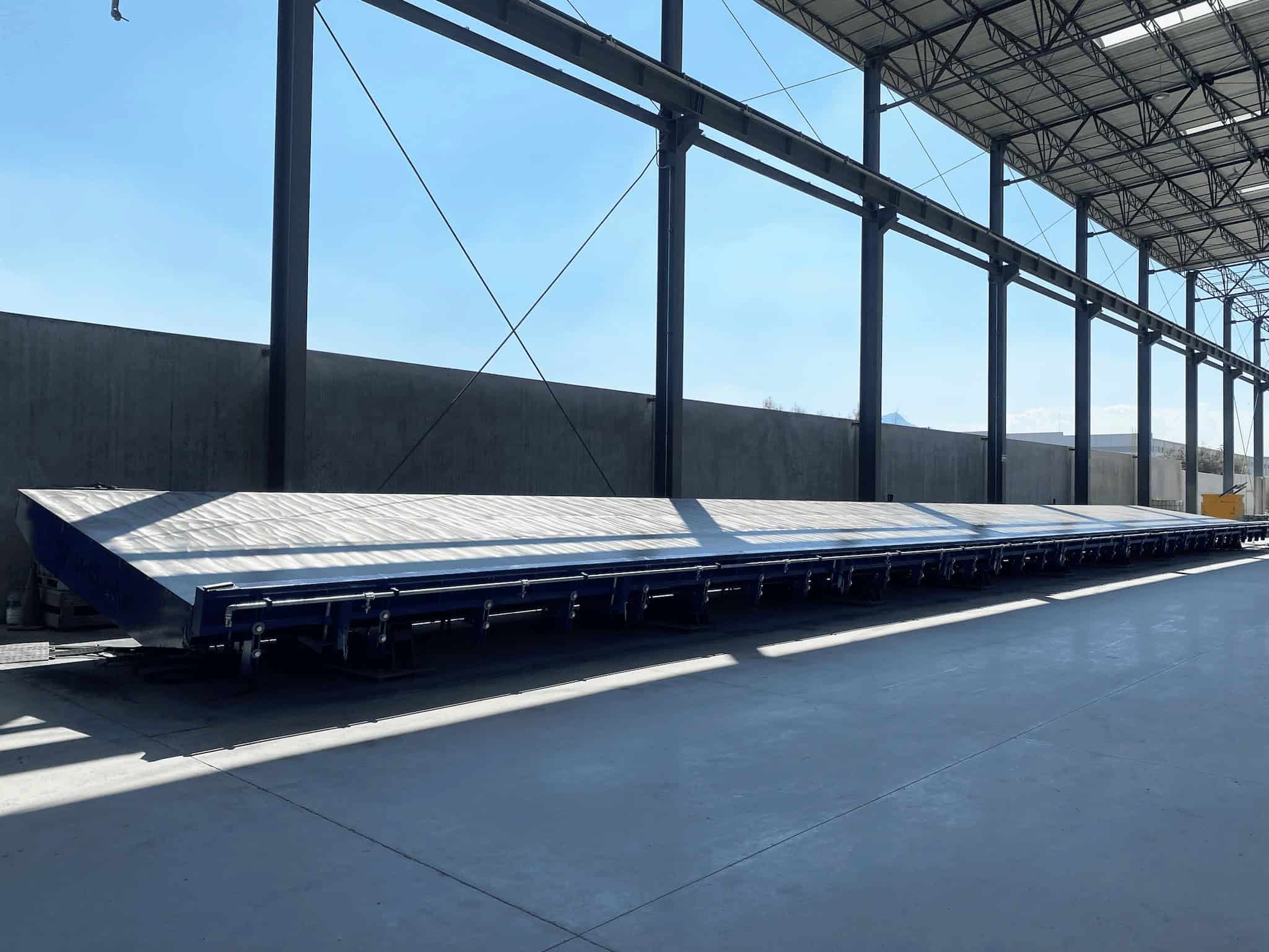

Moldtech has carried out the supply and installation of two tilting tables in Mexico, designed for the production of precast concrete panels.

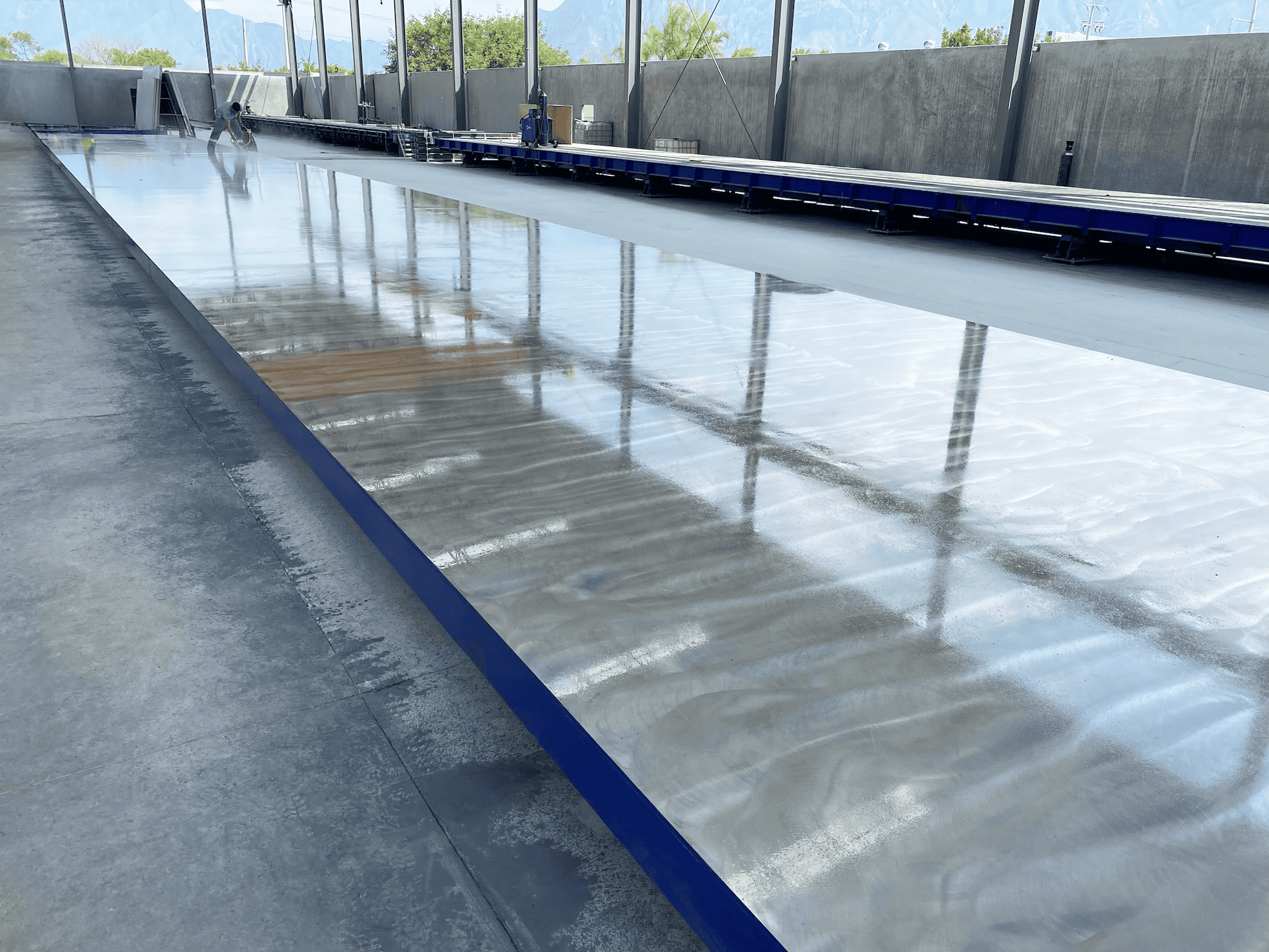

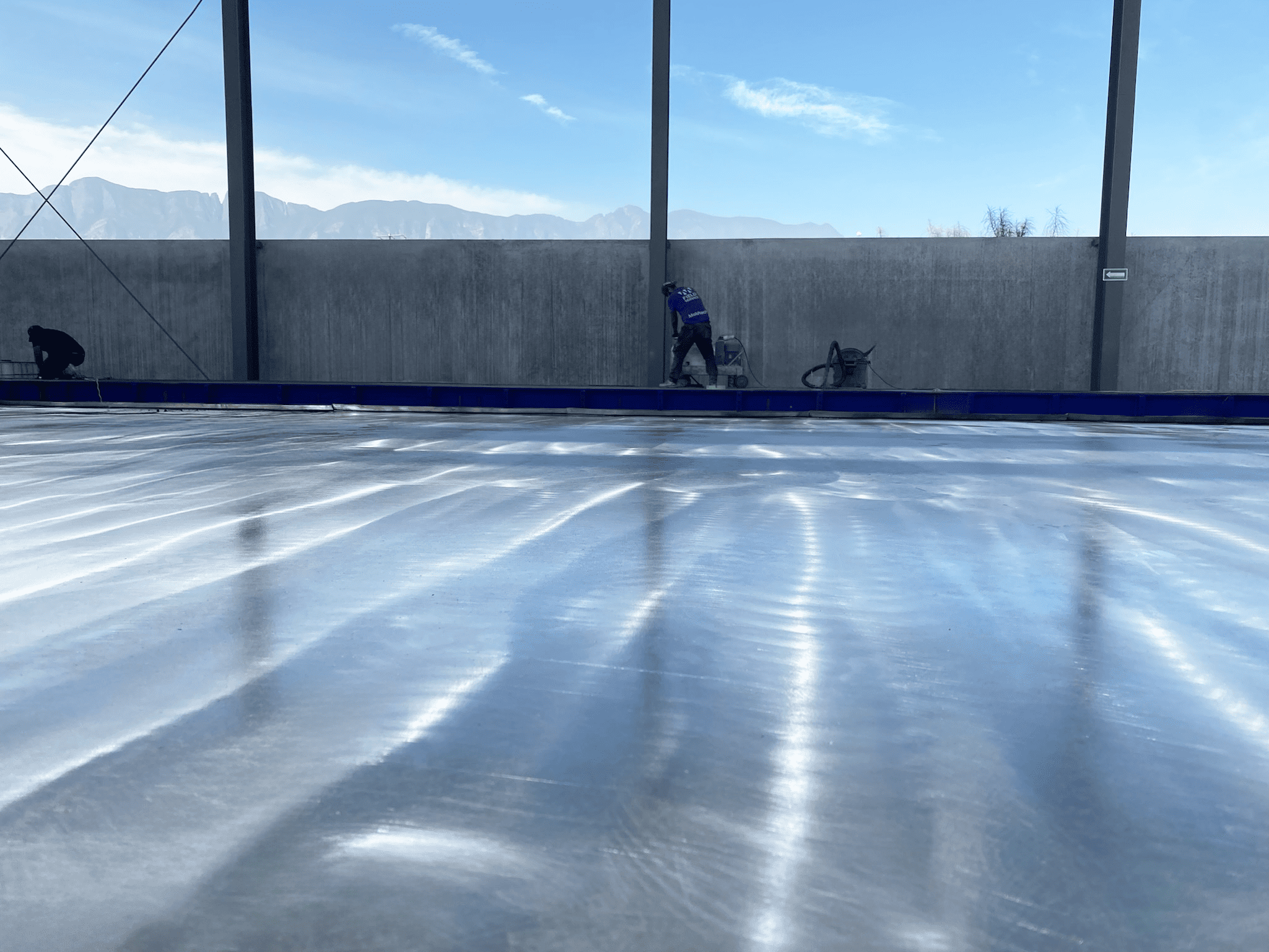

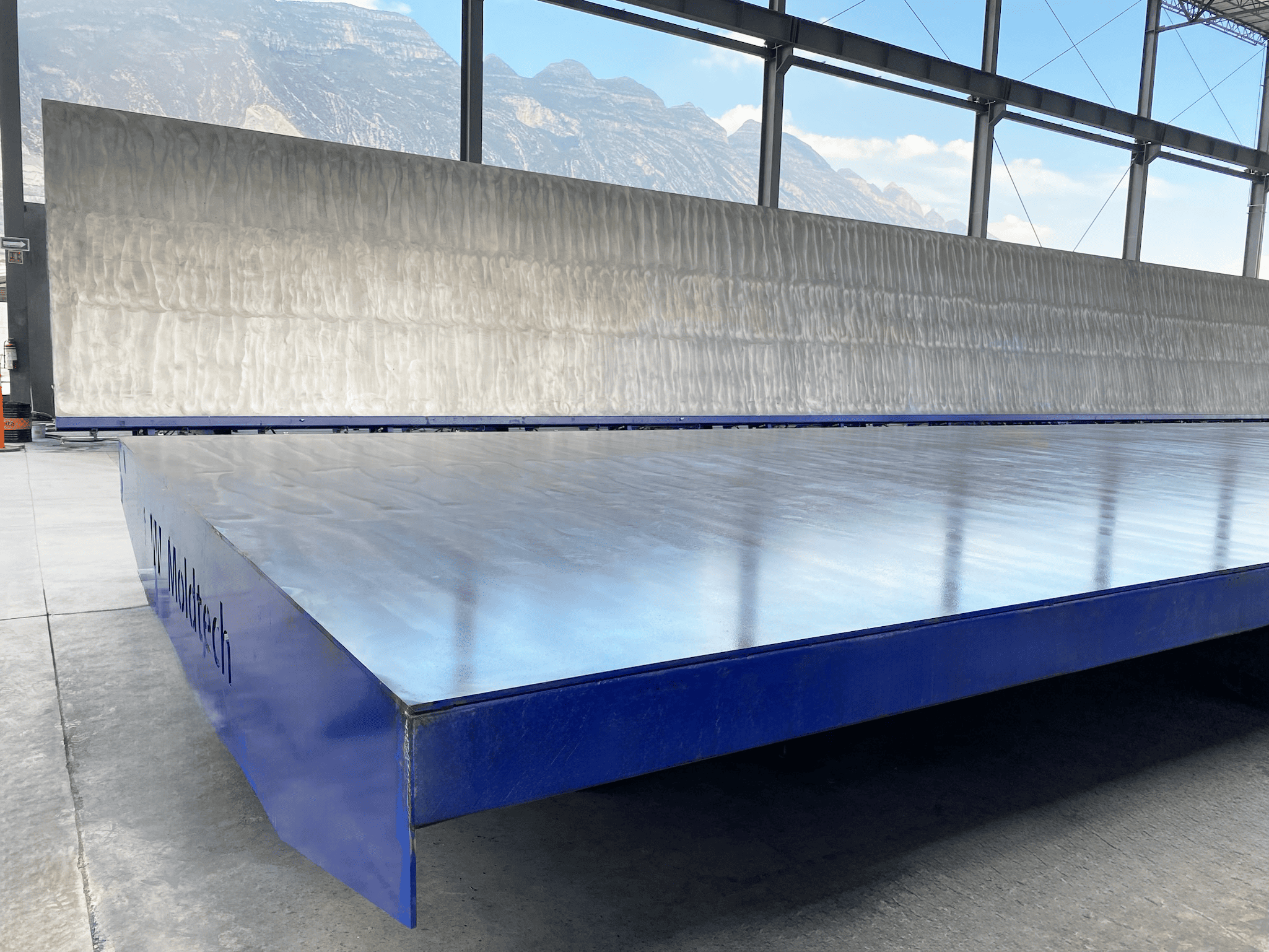

Each table, with dimensions of 35.4 meters in length and 4 meters in width, is composed of three modules which, once assembled, form a high-capacity production line. These tables allow the manufacture of panels with variable thicknesses ranging from 110 to 250 mm, ensuring maximum versatility in production processes.

The hydraulic tilting system enables safe and efficient demoulding of the panels, reaching a maximum inclination of 74°. In addition, the tables are equipped with a pneumatic vibration system and specific shuttering accessories, guaranteeing an excellent surface finish for each panel.

With this project, Moldtech reaffirms its commitment to delivering advanced technical solutions tailored to the needs of its clients, driving the modernization of precast plants and optimizing their production processes.