For the manufacturing of concrete columns.

Do you want more information?

Contact an expert from our team now

- +34 955 444 190

- info@moldtechsl.es

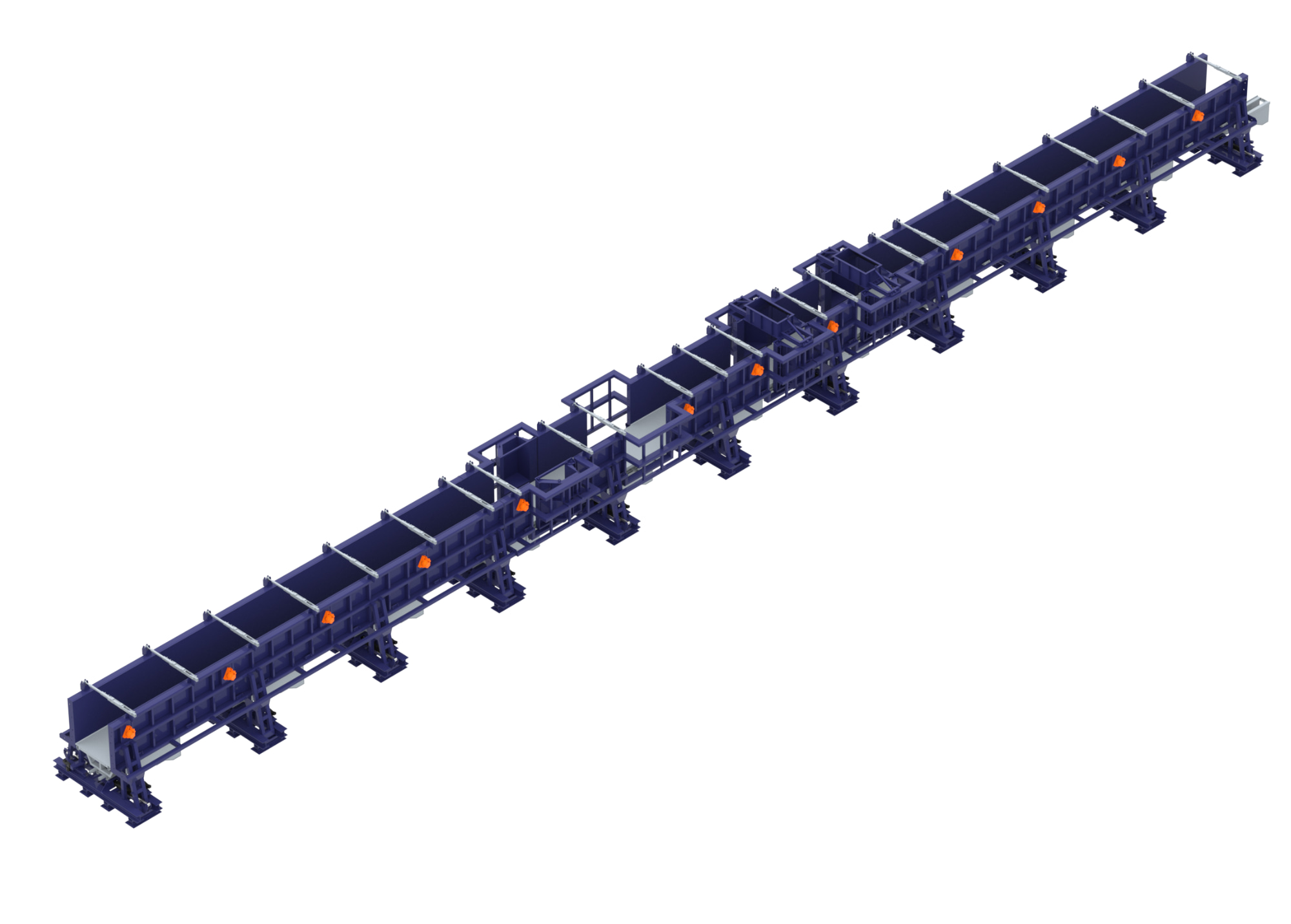

For the manufacturing of concrete columns.

Simple hydraulic mold for precast concrete columns with one molding line gives a possibility of producing a reinforced column with different sections. It allows the production of columns with corbels on up to 4 faces. For the mold opening system, a hydraulic system with synchronized cylinders is implemented. These cylinders move the base and both sides allowing easy removal of the prefabricated column. Having the mold opened, it is possible to remove the base and place another one for a different width, or even adjust the base in height, having the appropriate support. A more advanced option is the hydraulic adjustment of the height implemented to the base. There is a possibility to assemble several sections in order to increase production capacity, separating the columns from each other with the appropriate transversal shatters or stoppers.

Corbels manufacturing system in these molds is composed of the corbel formwork and a kind of boxes where this formwork is installed. Thus allowing a certain range of position variation and even replacing corbel molds with straight shutters that eliminate the corbel. As a complementary function, it is usual to incorporate an electrical or pneumatic vibration system into these molds, which improves the surface finish of the prefabricated column, as well as compacts the concrete when it is formulated with less water. Another productivity improvement is the one that can be carried out by means of heating systems. For this, a system of finned pipes for the circulation of hot water or steam is integrated into the different elements of the mold.