For the production of precast box culverts and half-frames by using wet cast concrete.

Do you want more information?

Contact an expert from our team now

- +34 955 444 190

- info@moldtechsl.es

For the production of precast box culverts and half-frames by using wet cast concrete.

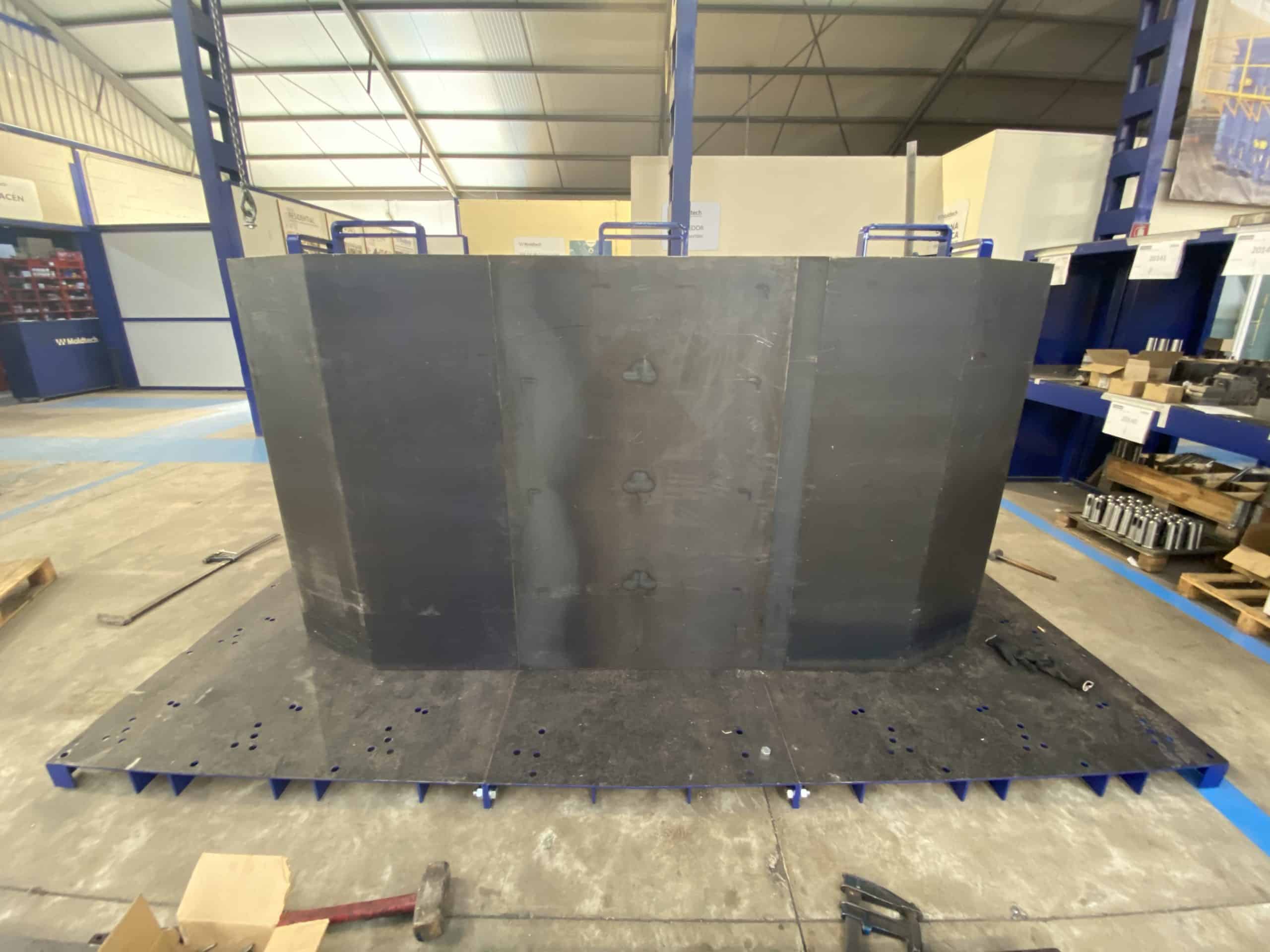

It’s a modulated system of steel formworks designed for the production of precast box culverts and half-frames by using wet cast concrete.

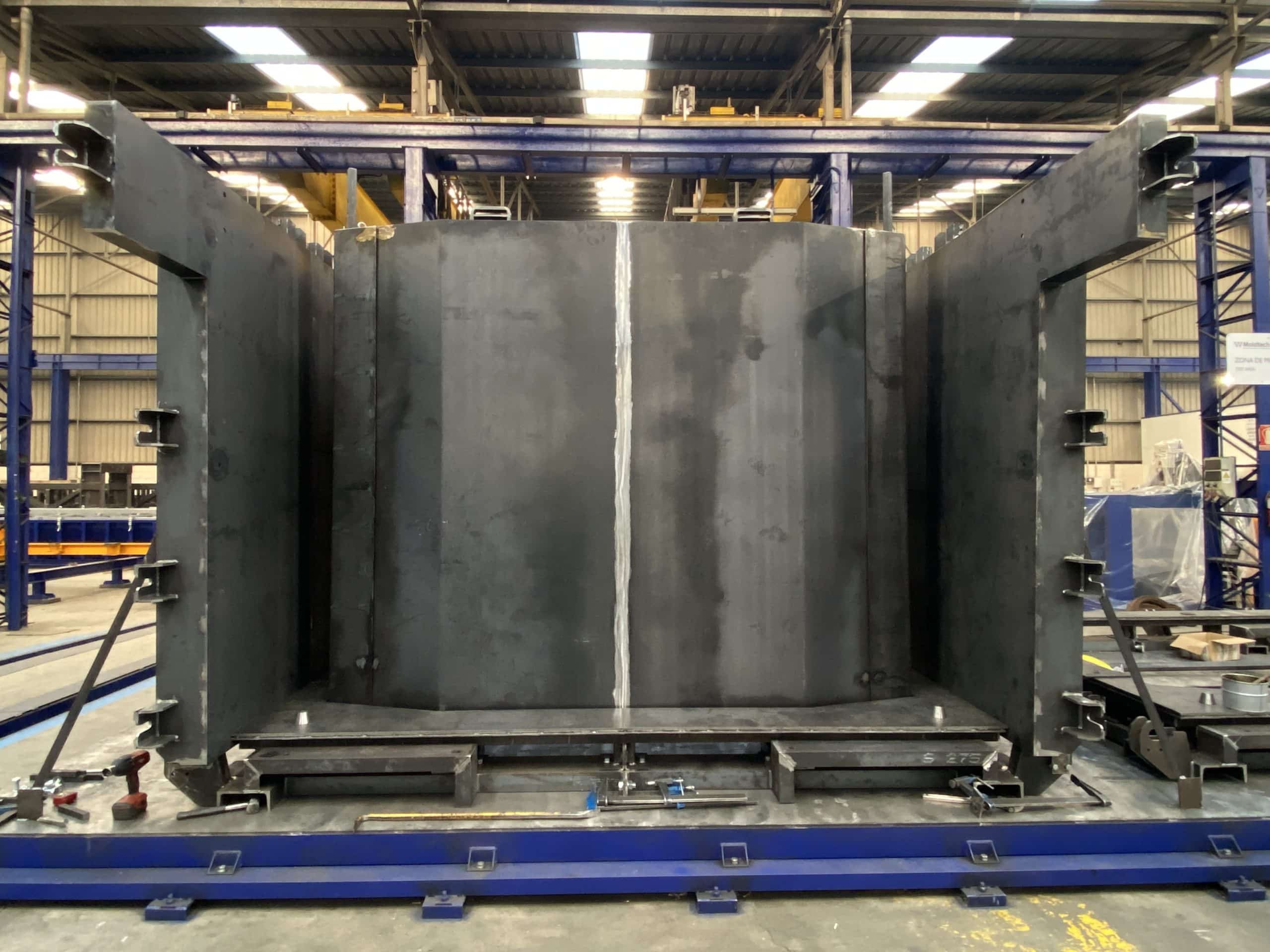

The assembly and the opening of the mould are performed manually, joining the amount of necessary elements or modules in accordance to dimensions of the frame to produce. Depending on the supplied set of formwork, is possible to reach up to 7m in width (distance between the pillars of the box culvert). The same fixing system is used to add additional supplements to the outer mould. That allows adjusting the thickness of the precast box culverts.

The bases are assembled by screw-nut unions, while the inner and outer moulds are assembled on this bases by bolt-wedge unions.

When demolding the piece, it is possible to remove the inner and the outer mould in four parts each, what implies that they don´t have to be totally disassemble and simplifies the production process for series of pieces with the same measures.

Spacing tubes with Dywidag rods and nuts are used as locking system in the upper part.

The formwork panels have sealing gasket to ensure the sealing of the mould. Like an option, the mould can count with specials formwork panels to cast corbels for supporting slabs. Other special formwork panels cast a flange for the retaining of soil on the precast box culvert. It is usual to design the modular mould to cast the box culverts and half-frames with male-female joints.

Related entries:

Precast Concrete Mouldings power – Revolutionizing Construction