Designed for the manufacturing of concrete panels.

Do you want more information?

Contact an expert from our team now

- +34 955 444 190

- info@moldtechsl.es

Designed for the manufacturing of concrete panels.

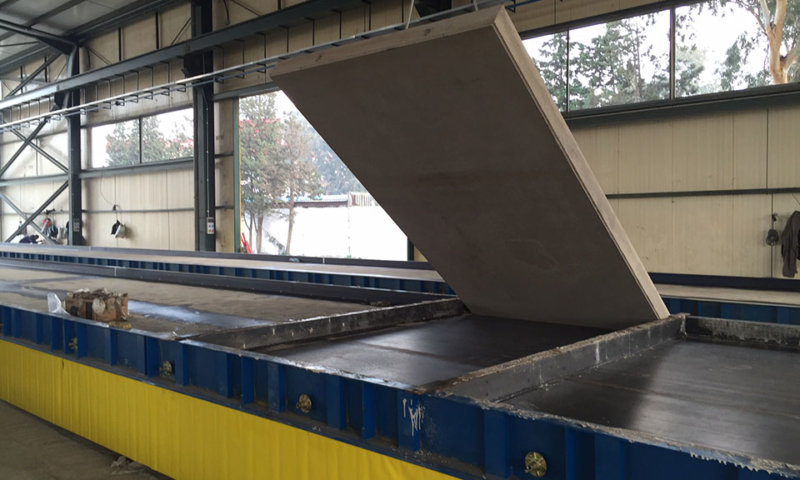

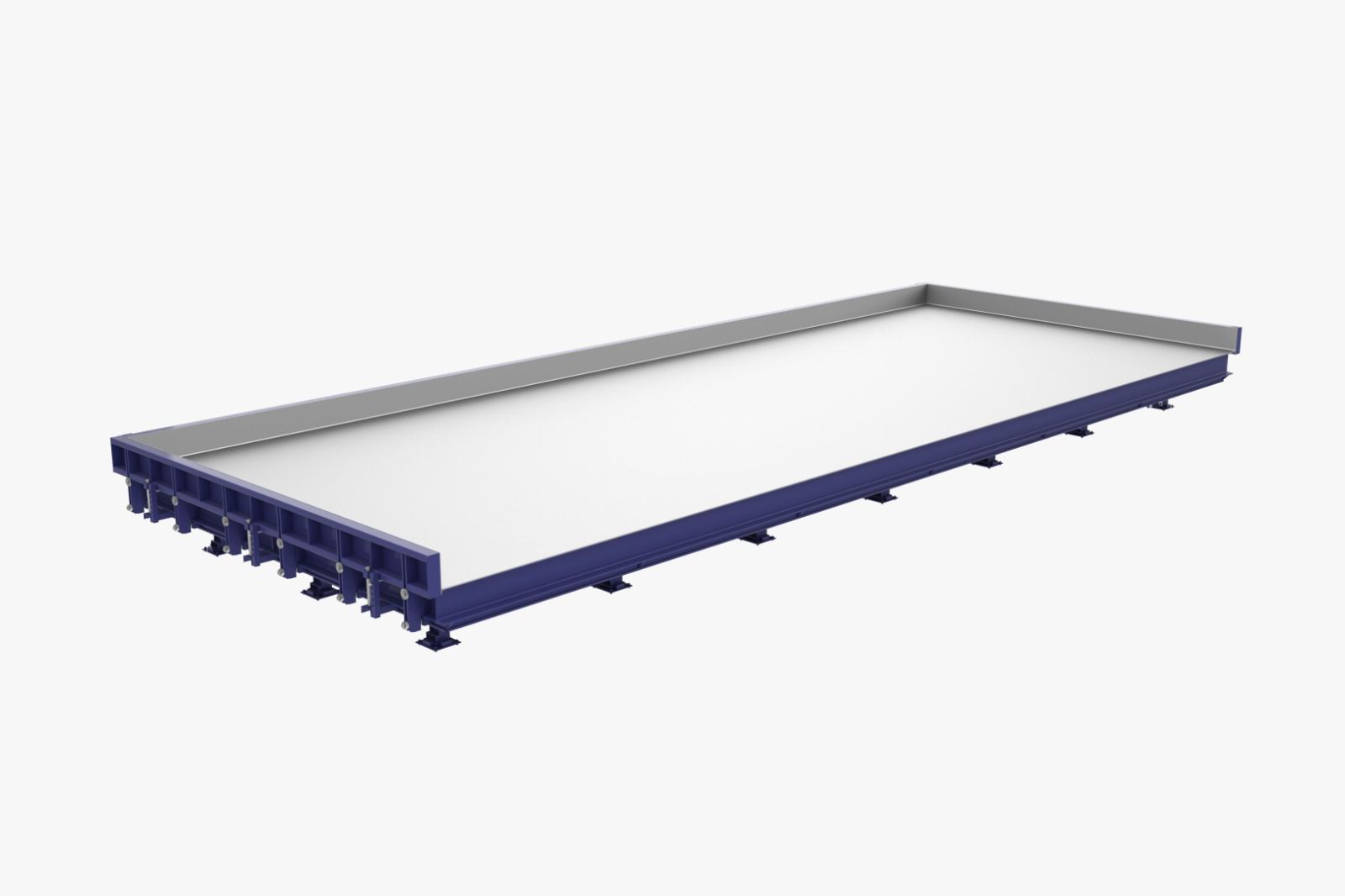

Wall panels are normally produced on tilting tables as these tables allow the panels to be taken out vertically and therefore earlier. However, when the project requires to reduce the investment amount or when the wall panels are only produced in limited numbers one can alternatively use less expensive fixed tables for the production of the wall panels.

The table width should take into account the maximum panel height. Usually, the table features 2 collapsible longitudinal sides to allow easy extraction of the panel. The casting dimensions of the panel can be adjusted with the help of different shuttering systems . The table is manufactured in modules with a length of 11.8 meters which are welded together by Moldtech installers during the time of commissioning in order to obtain the required length.

The tables can incorporate vibration (air or electric) systems and heating systems for a better concrete finishing and an accelerated concrete curing.

Basically, we can distinguish two types of fixed tables:

Although not very common, on some occasions the project requires wall panels with pre-stress. These tables are normally so-called self-stressing tables and allow the possibility to incorporate pre-stressed strands into the casted elements. The total pre-stress force capacity of the table can be custom-built in accordance with the specific requirements of the client. The pre-stressed strands make it possible the production of wall panels which use less reinforcement.

Discover our Precast Concrete Molds for Sale