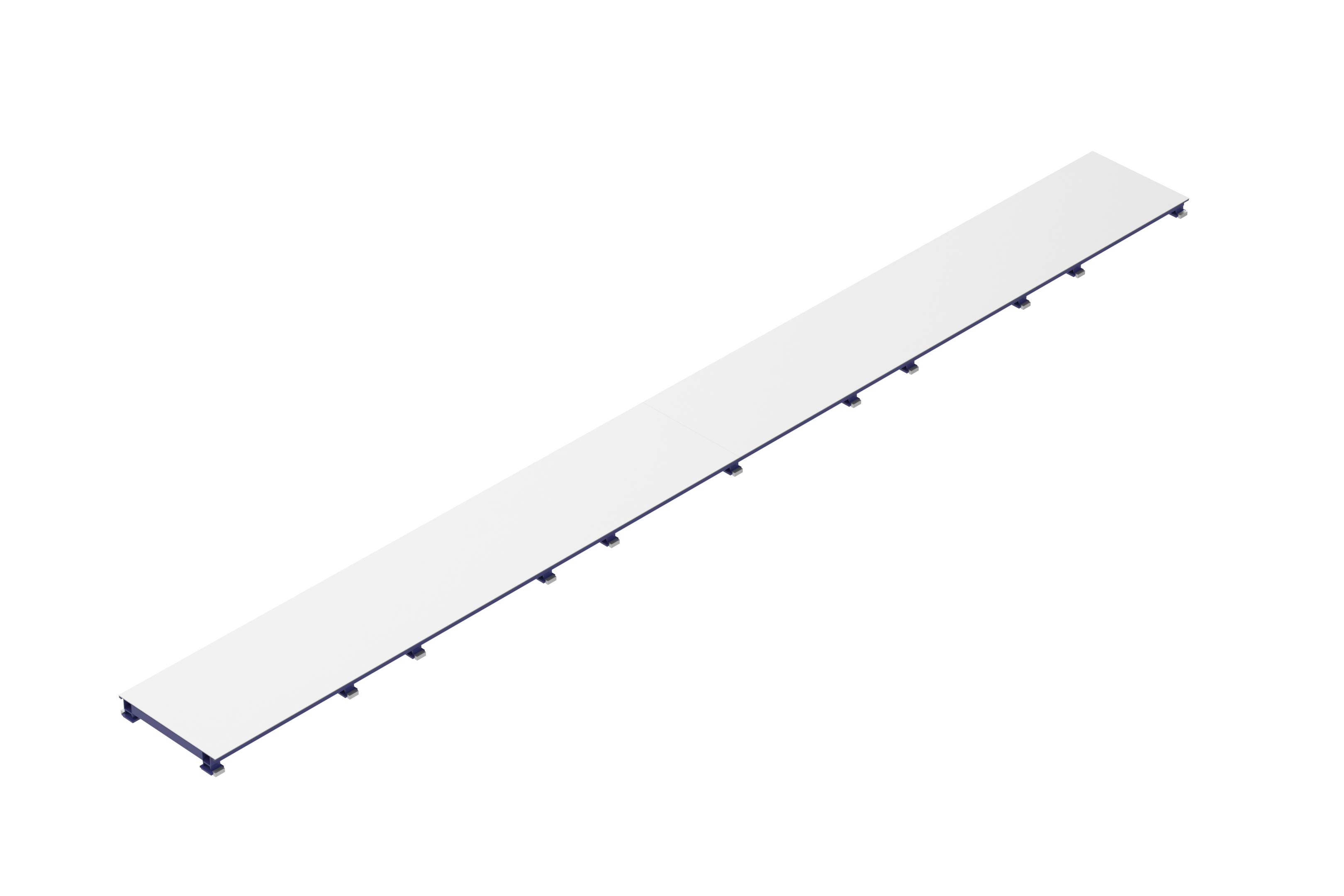

Universal tracks for the manufacture of prestressed elements for the production of concrete parts.

Do you want more information?

Contact an expert from our team now

- +34 955 444 190

- info@moldtechsl.es

Universal tracks for the manufacture of prestressed elements for the production of concrete parts.

Pre-stressed elements are manufactured on casting beds upon mold sides are placed. Using a pre-stressing system, comprised of stressing heads and hydraulic tensioning equipment, a set of steel strands are pre-tensioned in order to manufacture stronger concrete pieces.

Casting beds are comprised of a supporting structure with several drill holes to fix the baseplates and fasten the mold sides.

The baseplates can be manufactured with several supporting positions in order to regulate the height and change the lower flange of the beams. In addition, the baseplates include sealing gaskets in order to ensure a perfect sealing of the mold.

The casting bed system can feature a heating system on the floor in order to accelerate the concrete hardening.

Discover our Precast Concrete Molds for Sale