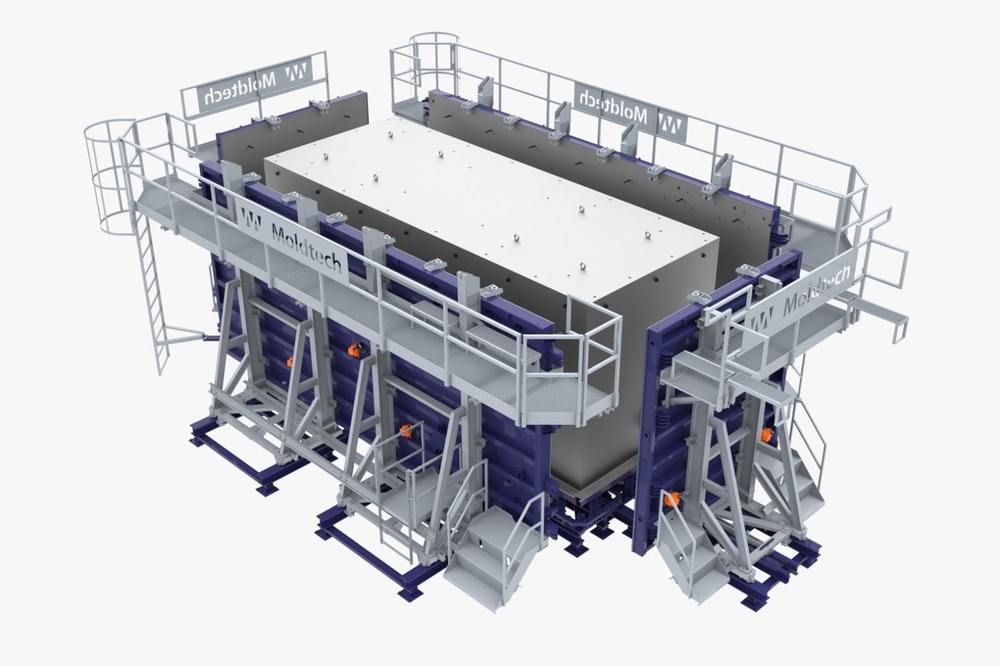

Modular Mold Systems are flexible precast solutions for the production of concrete elements. At Moldtech, we define them as interchangeable mold components that adapt to various project needs, from wall panels to complete volumetric units. By integrating the term Modular Mold Systems from the beginning, we guarantee clear SEO positioning. These systems have revolutionized the precast industry, offering faster delivery times, less material waste, and greater customization. Thanks to our experience in projects such as 3D molds for modular housing in Chile (Moldtech promotes the manufacture of modular housing in Chile), we have seen a reduction in production cycles of up to 50% and a 90% decrease in on-site waste.

Why Choose Modular Mold Systems?

The Versatility of Modular Mold Systems

Why settle for a single-purpose mold? A common mistake we see is choosing high-volume, inflexible tools. Modular systems allow for insert changes, dimension modifications, and multiple element types to be handled on the same base. In Miami, our 3D molds for bathroom modules were adapted from single-bathroom runs to multi-unit configurations with minimal downtime.

Key Benefits

- Cost-effectiveness: Modular designs reduce tooling investments and spare parts inventory.

- Time efficiency: Faster mold changeovers and parallel workflows shave weeks off project schedules.

- Customization: Tailor each module (wall thickness, location of built-in elements, surface finishes) to exact specifications.

Design and Engineering Behind Modular Mold Systems

Design and Engineering

Our design process begins with 3D modeling and finite element analysis to anticipate stress points. We asked ourselves, “What if the client needs to modify the dimensions mid-project?” This question guided the flexible geometry of our molds in the Chilean housing project, where lengths ranged from 5 to 7 m and heights from 2.5 to 3 m.

Innovation in Manufacturing

Innovation lies in the integration of hydraulic lifters, pneumatic vibrators, and quick-change inserts. For example, our PPVC contracts in the Philippines, Singapore, and New Zealand use hydraulic actuators for precise opening/closing and internal retraction. This technology is the result of years of R&D, and yes, we have had to recalibrate cylinder positions several times to achieve a perfect seal, but this is how we learn.

Real-World Applications

- Prefabricated Housing (Chile): Our 3D molds delivered flexible modules, cutting construction time almost in half.

- PPVC Projects (Global): In the USA, Singapore, and beyond, Moldtech’s PPVC molds produce complete volumetric units with consistent quality.

- Bathroom Modules (USA): Adjustable 3D molds for Miami’s bathroom pods proved our system’s adaptability under tight production rhythms.

How Moldtech Supports Your Needs

Tailored Solutions

We don’t believe in off-the-shelf answers. From initial consultation to on-site assembly, our team works closely with clients. In one industrial facility, we redesigned a fixing system mid-process to accommodate composite, solid, and lightweight wall panels, as real-world projects require immediate adjustments.

Ongoing Support

After installation, we continue to collaborate: we train your operators, optimize cycle times, and update inserts as your portfolio evolves. This means you avoid the downtime typical of legacy molds and continue moving forward.

Wrapping Up Modular Mold Systems and Their Importance

Modular mold systems are more than just molds: they boost productivity. By combining versatility, speed, and customization, they redefine the possibilities of prefabrication. If you’re considering modular solutions for your next project, we’re here to help. Contact our team to explore custom, hydraulically actuated, 3D-ready systems tailored to your needs.