In the world of construction, I-beams are a fundamental building block for safer, more functional and sustainable construction. In the mid-20th century, I-beams began to be manufactured in precast concrete, combining the efficient shape of the I-beam with the advantages of concrete in terms of strength, compressive strength and durability. This evolution allowed their use in an even wider variety of applications, including residential and commercial buildings, as well as large infrastructure projects.

This “I” shaped structural component redefines the way we design and build. But what makes them so special?

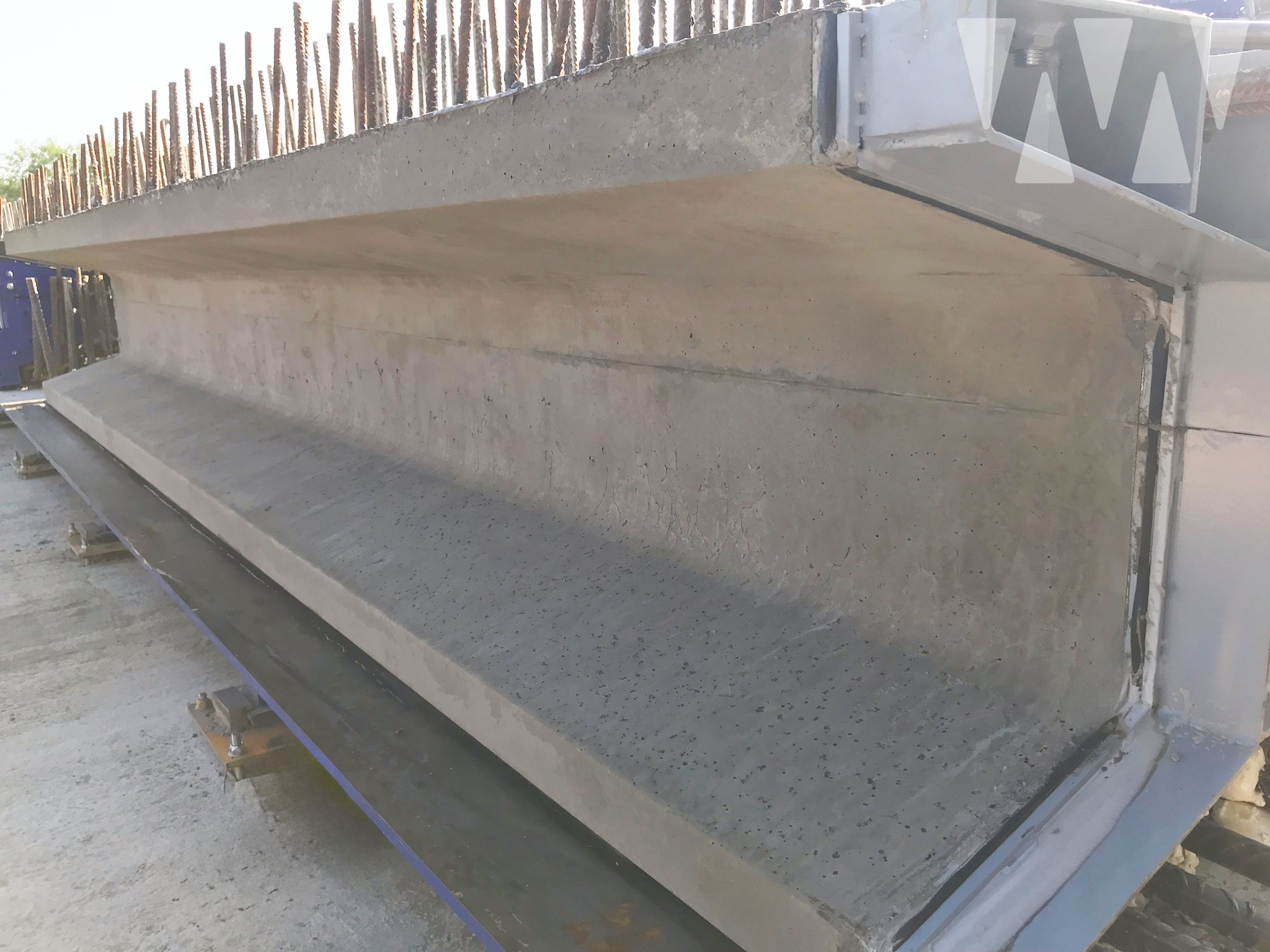

I-beams are transforming modern construction thanks to their intelligent design. How do they do it? It all comes down to their structure: a central bar called the “leg” that connects two horizontal “shelves”.

This simple but effective shape allows I-beams to support heavy loads with less material used for its production, meaning lighter but equally strong constructions, making them an ideal choice for projects that require an extremely robust structure.

Concrete I-beams are not only strong, but also sustainable. By using an I-beam design, these beams require less material to provide the same strength as a conventional beam. Less concrete means less CO2 emissions in production, which means less environmental impact. In addition, because they are prefabricated, quality control is greater, ensuring a long service life and reduced maintenance.

Precast concrete I-beams can be adapted to a variety of civil and industrial projects. Their modular design allows them to be used in various configurations, which facilitates their integration into any type of structure, guaranteeing both stability and aesthetics.

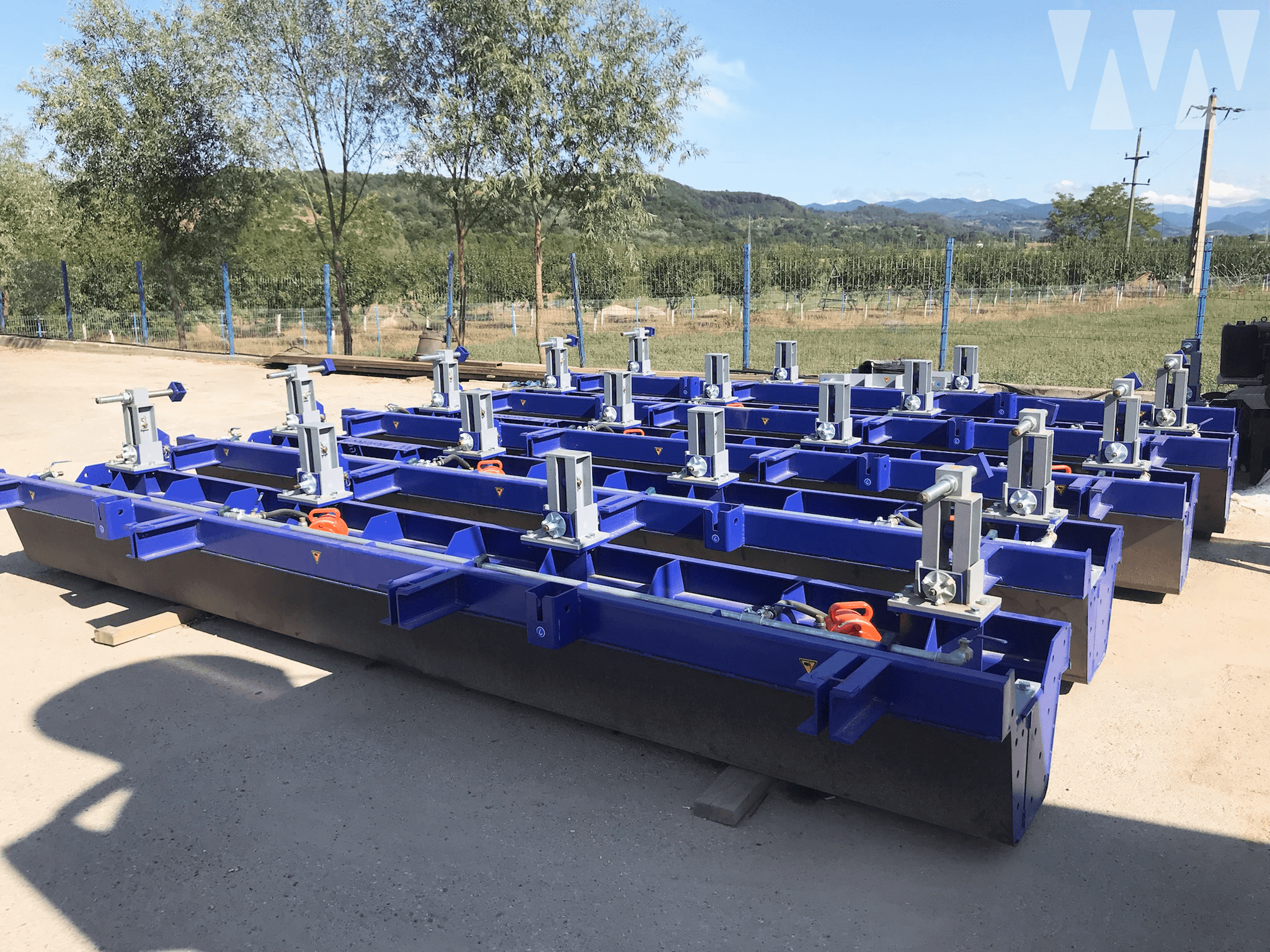

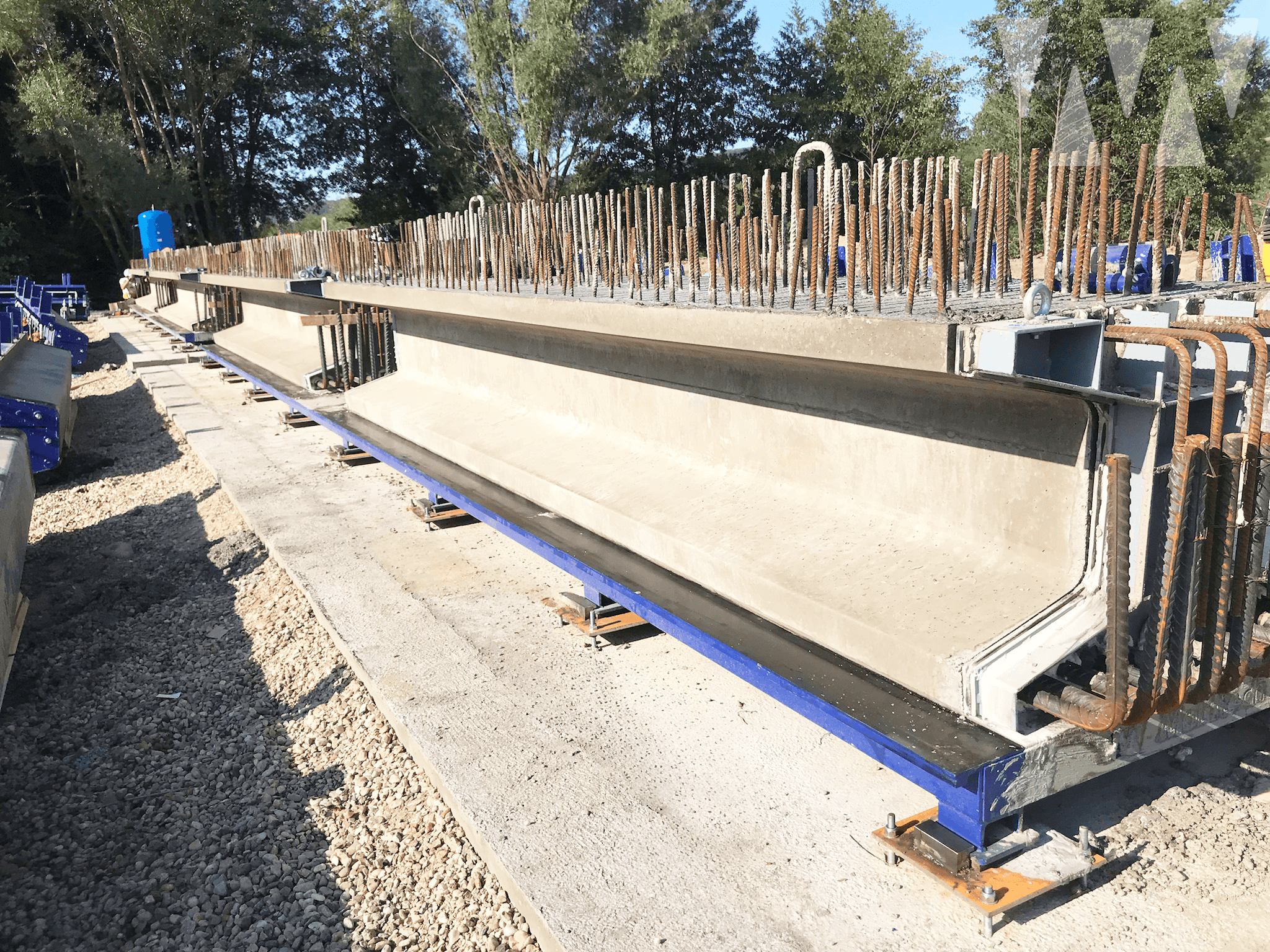

Moldtech recently supplied a new customer in Romania with four 10.6-metre-long modules of universal casting bed, together with four sets of 10-metre-long side moulds.

Our customer will use the beams in a port infrastructure project. This delivery will allow him to tailor different configurations according to the needs of the project, which is crucial in a demanding environment such as maritime environment.

With its access to the Black Sea, Romania has been developing port infrastructure using concrete. These projects are essential to the country’s trade and economy, and concrete is chosen for its resistance to adverse marine conditions, such as corrosion and heavy loads.

The future of precast concrete construction in Romania is promising, with a combination of historical experience and adoption of modern technologies ensuring that this material remains central to the country’s development.