Moldtech, a leader in precast concrete solutions, has strengthened its presence in the UK with the supply of a fixed table for a prestigious construction company.

This project represents a further step in our track record of designing and manufacturing high-performance equipment for key infrastructure.

A tailor-made solution for our client

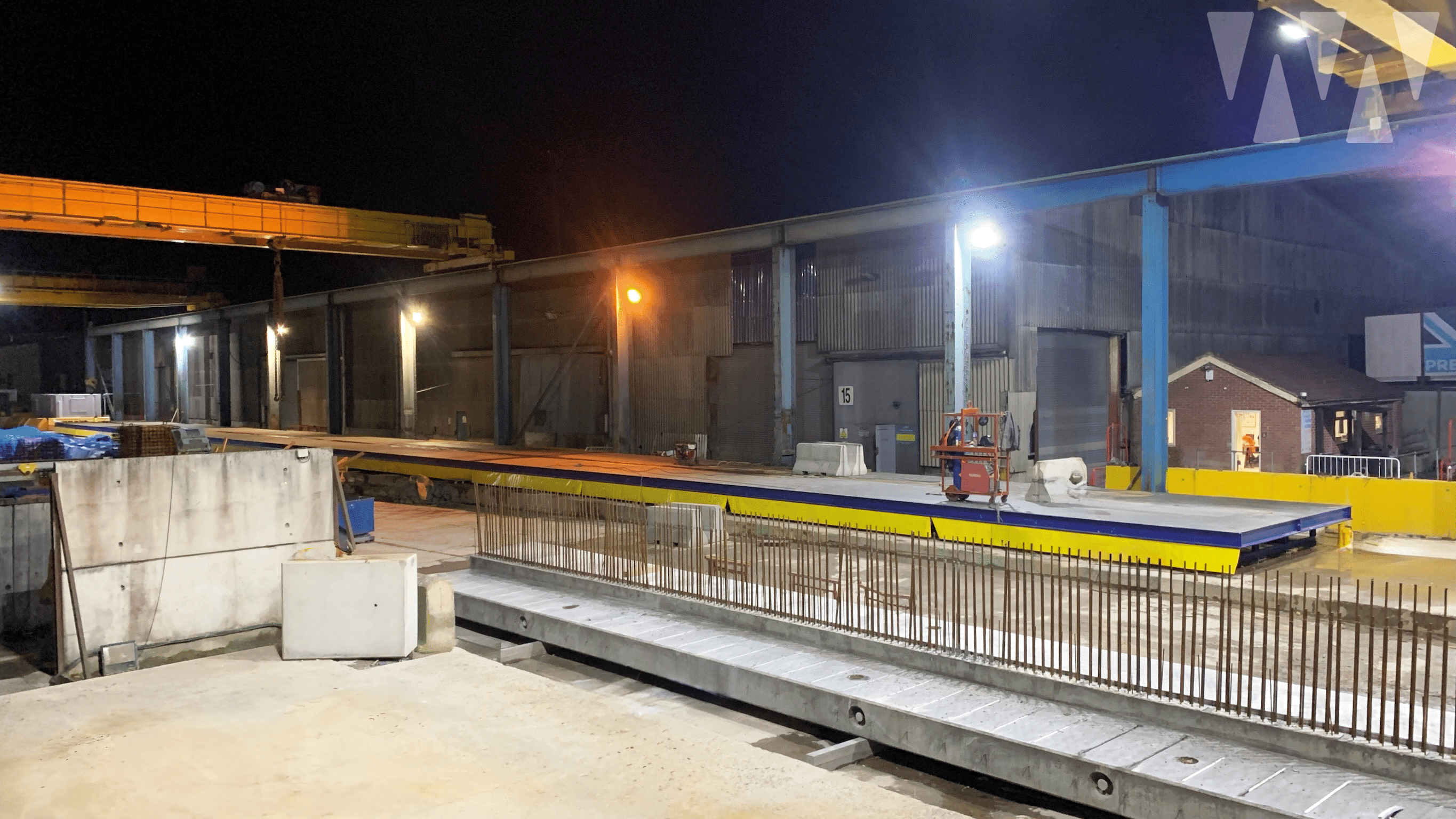

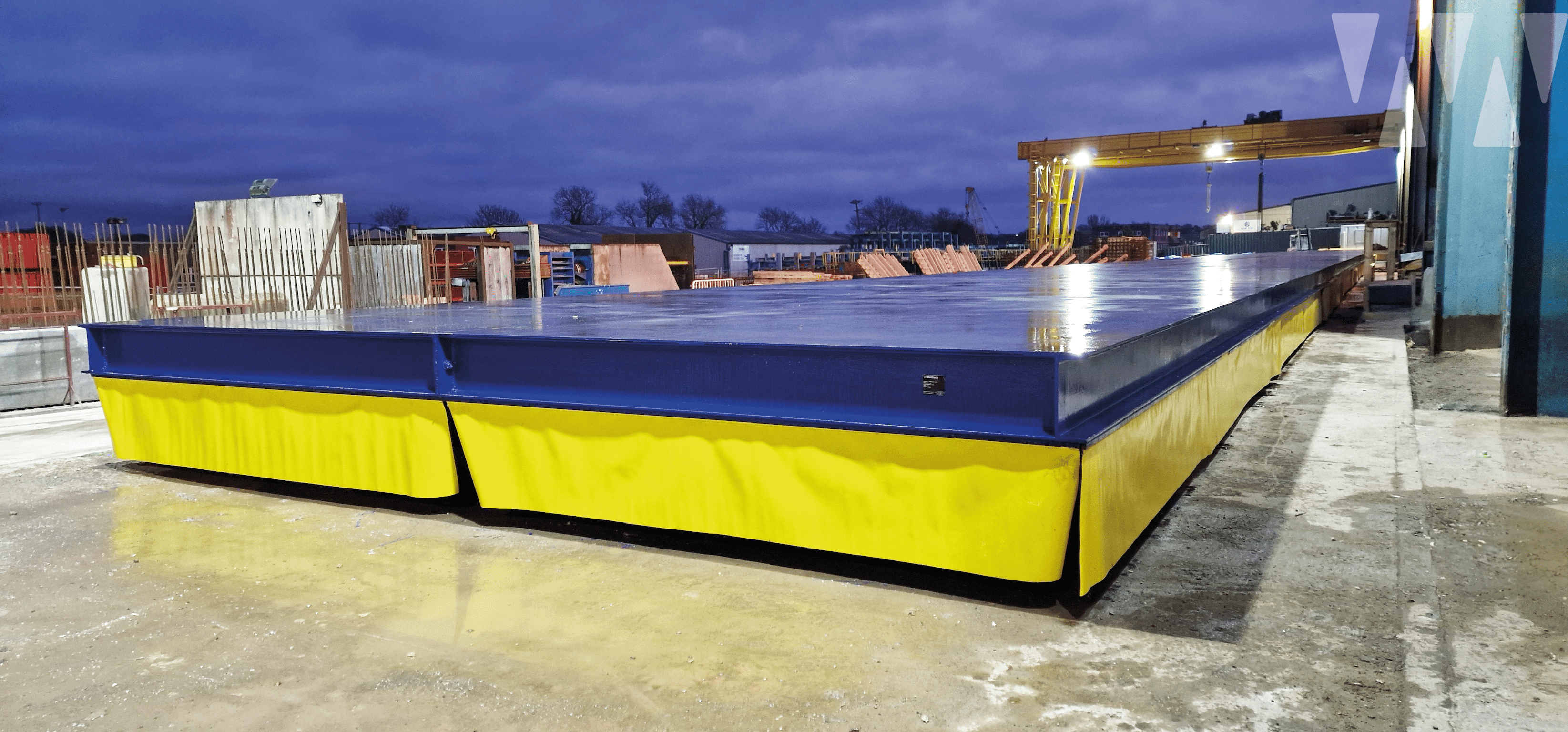

The fixed or stationary table delivered has been custom designed and manufactured in our facilities to the highest standards of quality and precision. This table, which has a robust structure and a perfectly level surface, is intended for the production of precast concrete panels to be used in bridge panel manufacturing projects in the UK.

Due to its customised design, the table offers versatility to manufacture panels of different sizes and thicknesses, adapting to specific project requirements. The resulting panels will be used as lost formwork and structural elements in key infrastructure, ensuring durability and strength in high performance applications. In addition, it includes optional vibration systems that ensure uniform compaction of the concrete, guaranteeing flawless finishes.

Sector-transforming benefits

Production with millimetre precision: The level surface of the tables guarantees homogeneous finishes, essential for avant-garde architectural projects.

Efficiency on a large scale: Ideal for mass production, these tables reduce time and costs, making them a key resource for precast manufacturers.

A commitment to sustainability: By minimising material waste and facilitating cleaner processes, fixed tables contribute to more environmentally friendly construction.

Versatility without limits: They allow working with panels of different sizes and thicknesses, adapting to different applications.

Bridge panels: precision engineering

The concrete panels manufactured with this fixed table are specifically designed for bridge applications, offering key technical advantages:

- Structural panels: Used as the base of the bridge, these panels support dynamic and static loads, complying with international structural safety standards.

- Deck slabs: Panels that distribute traffic loads to the beams, with an optimised design to resist constant impacts and vibrations.

- Safety barriers: Precast panels that act as lateral protection elements, guaranteeing the safety of vehicles and pedestrians.

- Extreme durability: Panels are treated to withstand harsh environmental conditions, including freeze-thaw cycles, exposure to water and salinity, and high traffic loads.

The future of precast is here

Precast is gaining ground globally, and fixed tables are positioned as a technological solution driving innovation in the industry. Their ability to integrate precision, speed and sustainability not only transforms the way we build, but also redefines quality standards in the industry.

In a world where time is money and resources are limited, investing in technologies such as fixed tables for precast concrete is not only a strategic decision, but a step into the future of construction.

With this project, Moldtech continues to consolidate its position as a strategic partner in the global precast sector. The collaboration with this client highlights our commitment to offer innovative solutions that adapt to the specific needs of each client, always maintaining the values of quality, reliability and sustainability that characterise our company.

We are proud to be part of the projects that are transforming the UK construction landscape and to continue to make a difference with each new challenge.