Once again Moldtech keeps meeting challenging delivery terms, even amid the difficult situation of worldwide supply chains and quarantine regulations in the spring of 2020, in this case delivering a mould for crane counterweights.

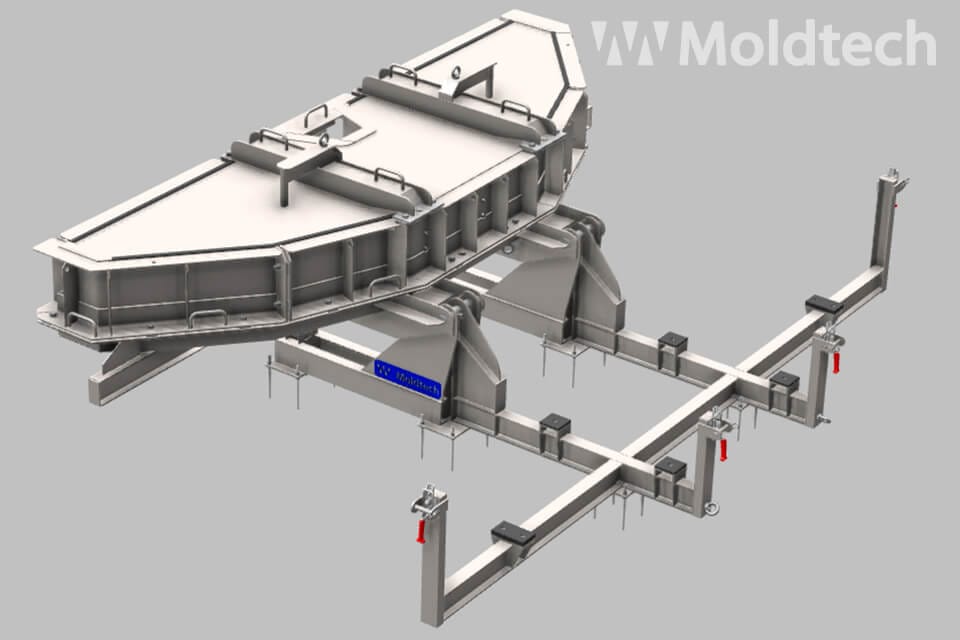

This special mould is built with 4 detachable parts that are bolted together and onto a bottom baseplate to form the special geometry of these counterweights. This mould is also assembled hinged onto a frame that allows turning it 180º with the help of the crane to fill with concrete in the most suitable position and flip it for better demoulding.

The counterweights are casted with special recesses that are made with steel formers that are bolted inside the mould walls and removed after curing, before demoulding. Once removed, these steel formers are fixed on the turning frame with quick locks.

The turning frame is built with neoprene pads to support the mould in both positions and to avoid damage while turning.

Design and manufacturing of this mould were a great challenge for our team, due to the strict tolerances and special requirements which were a step beyond normal standards of the sector.

|