Moldtech announces a new supply of moulds ZPX to Romania, intended for the construction of railway barriers in a project that will connect the border with Hungary and the Black Sea

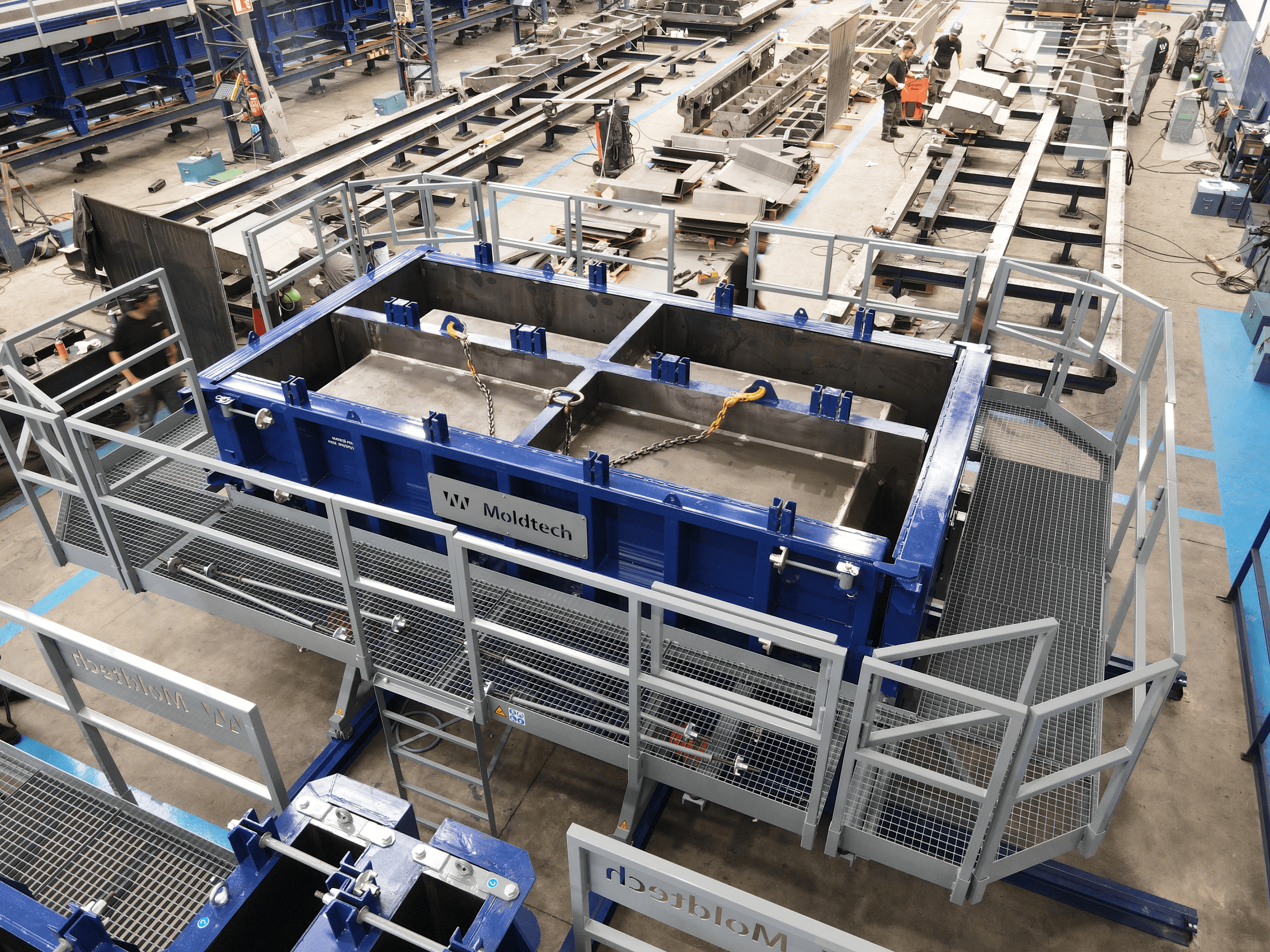

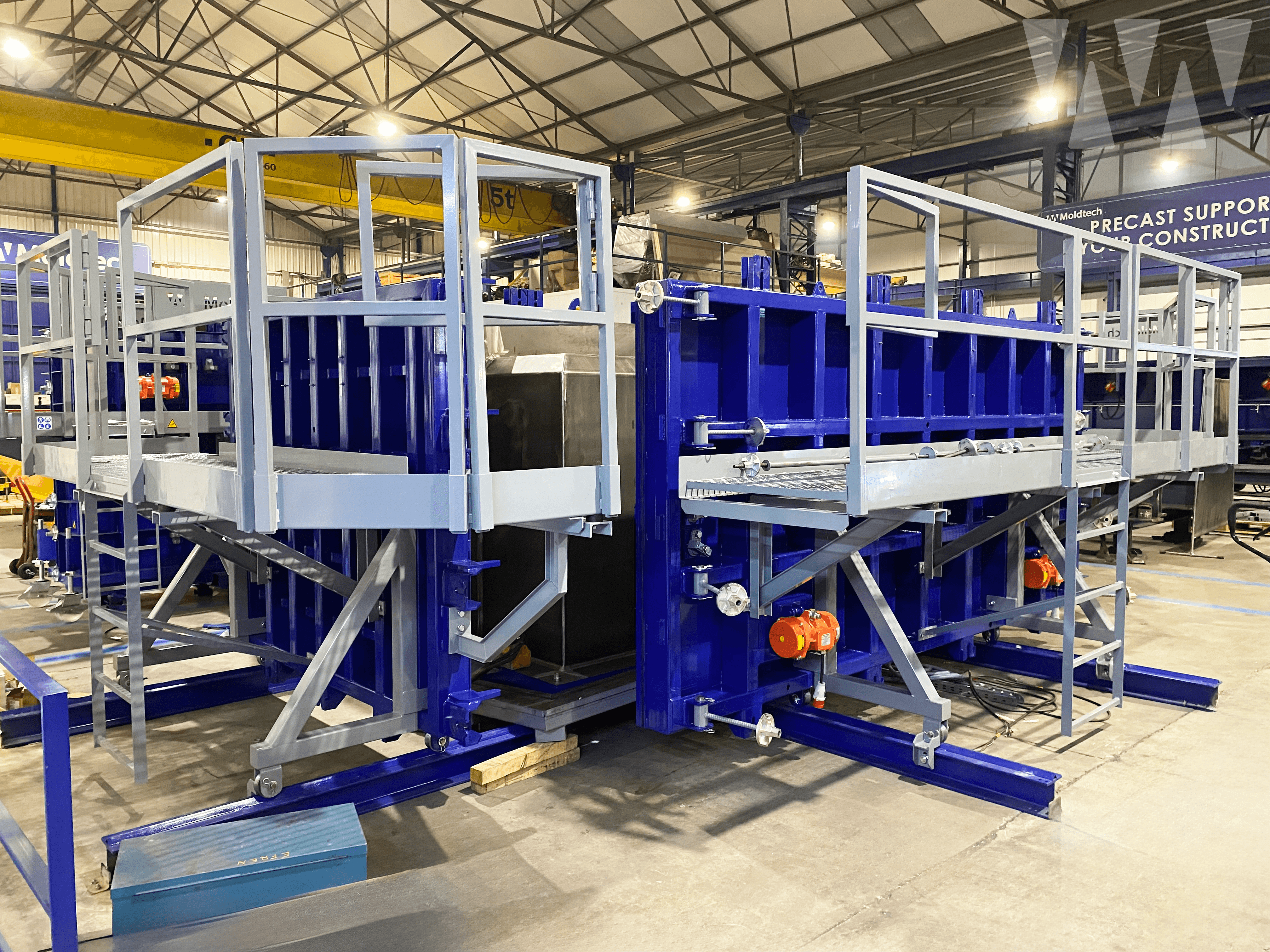

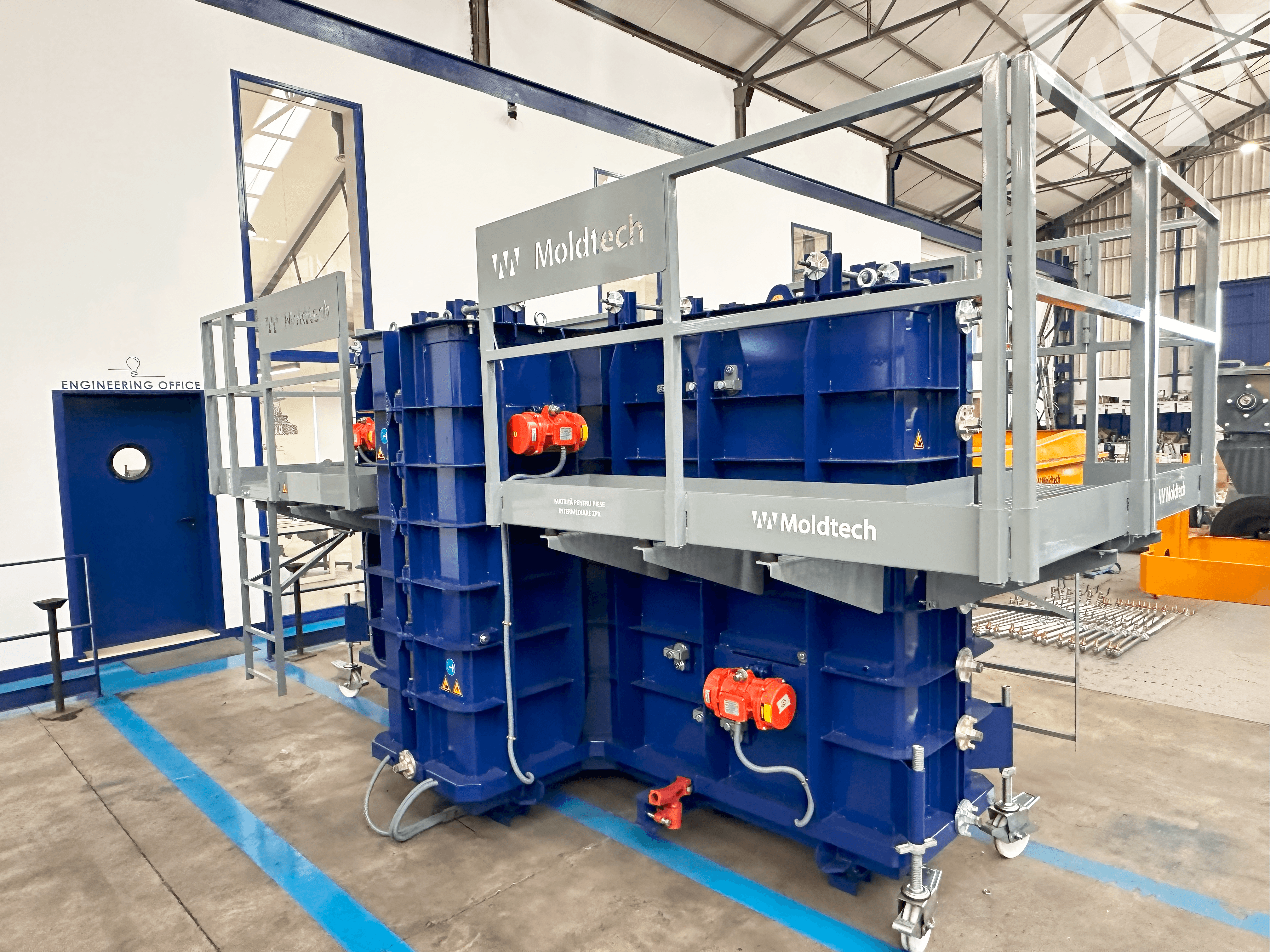

The Spanish company is a benchmark in the production of equipment for the precast sector, offering solutions that meet the highest standards. The moulds ZPX are Moldtech‘s latest supply to the Romanian railway project, intended for the manufacture of concrete barriers that will be used to delimit and protect critical areas of the railway track.

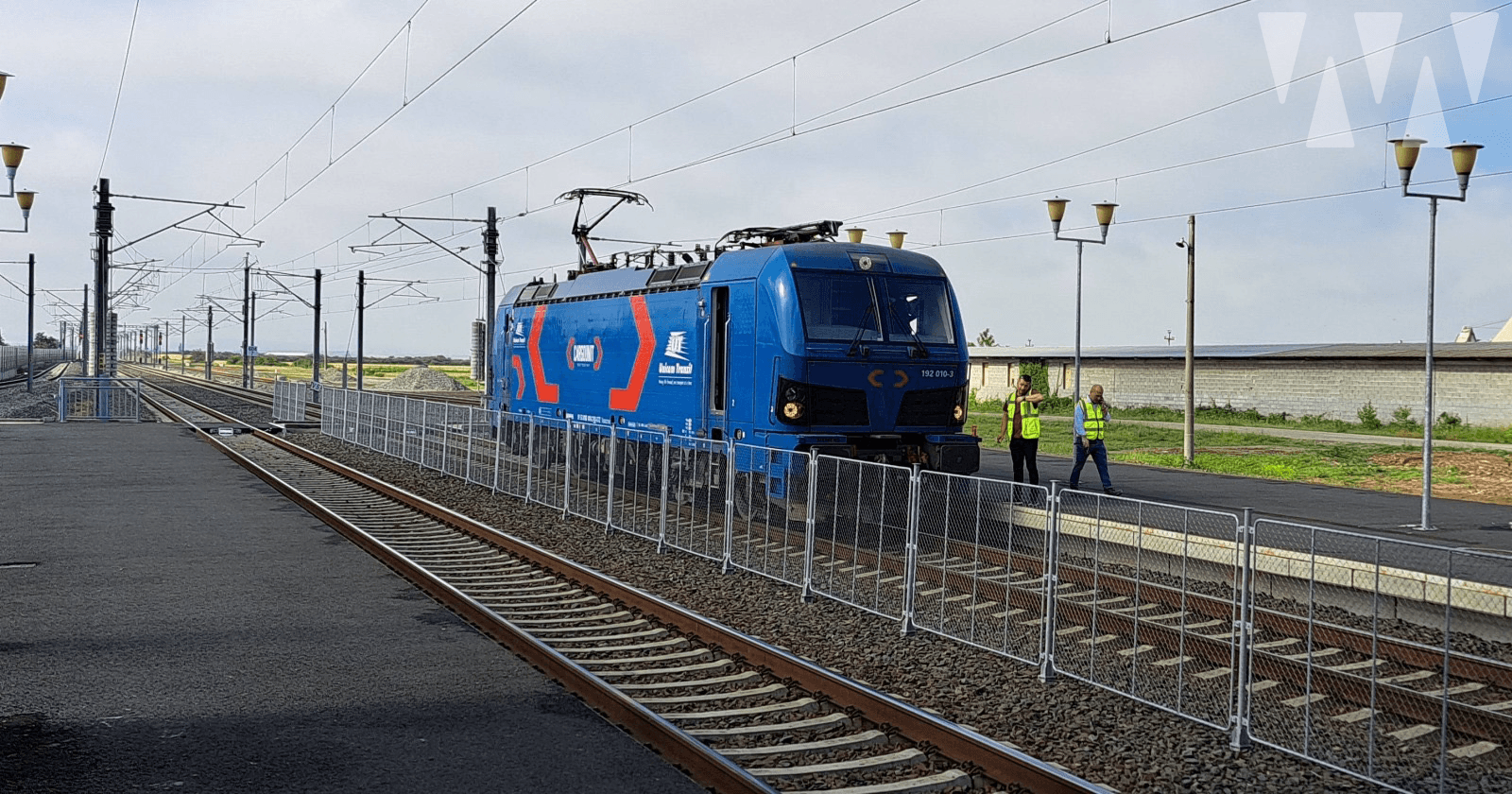

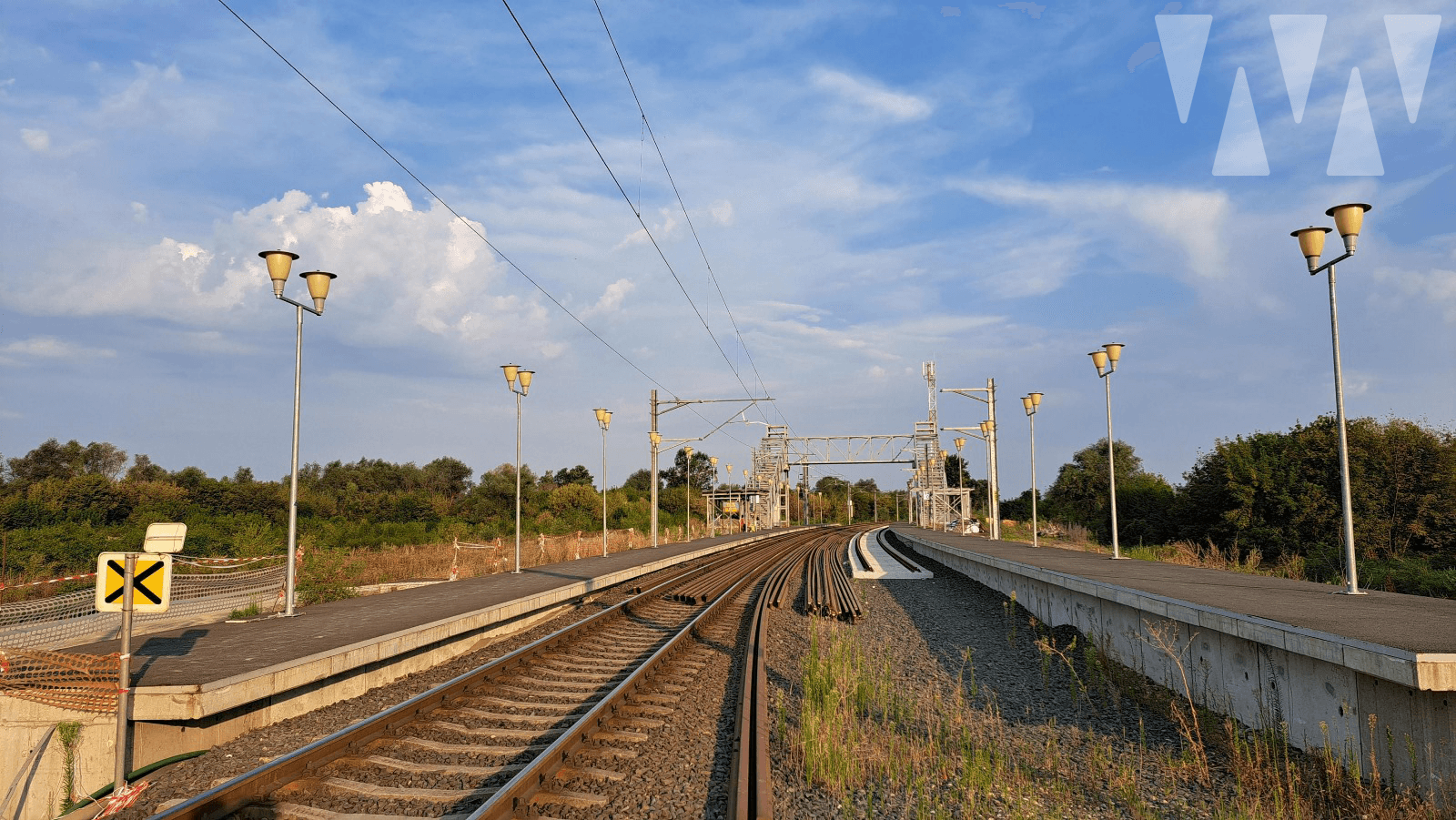

Precast concrete barriers play an essential role in railway infrastructure, especially in areas near stations and pedestrian crossings. In this project, the precast barriers will be used to create walls that will delimit the areas of the road, providing additional security to passengers and maintaining the integrity of the facilities. In addition, these barriers will function as the structural base for the platforms, where concrete slabs will be placed to wait for the trains.

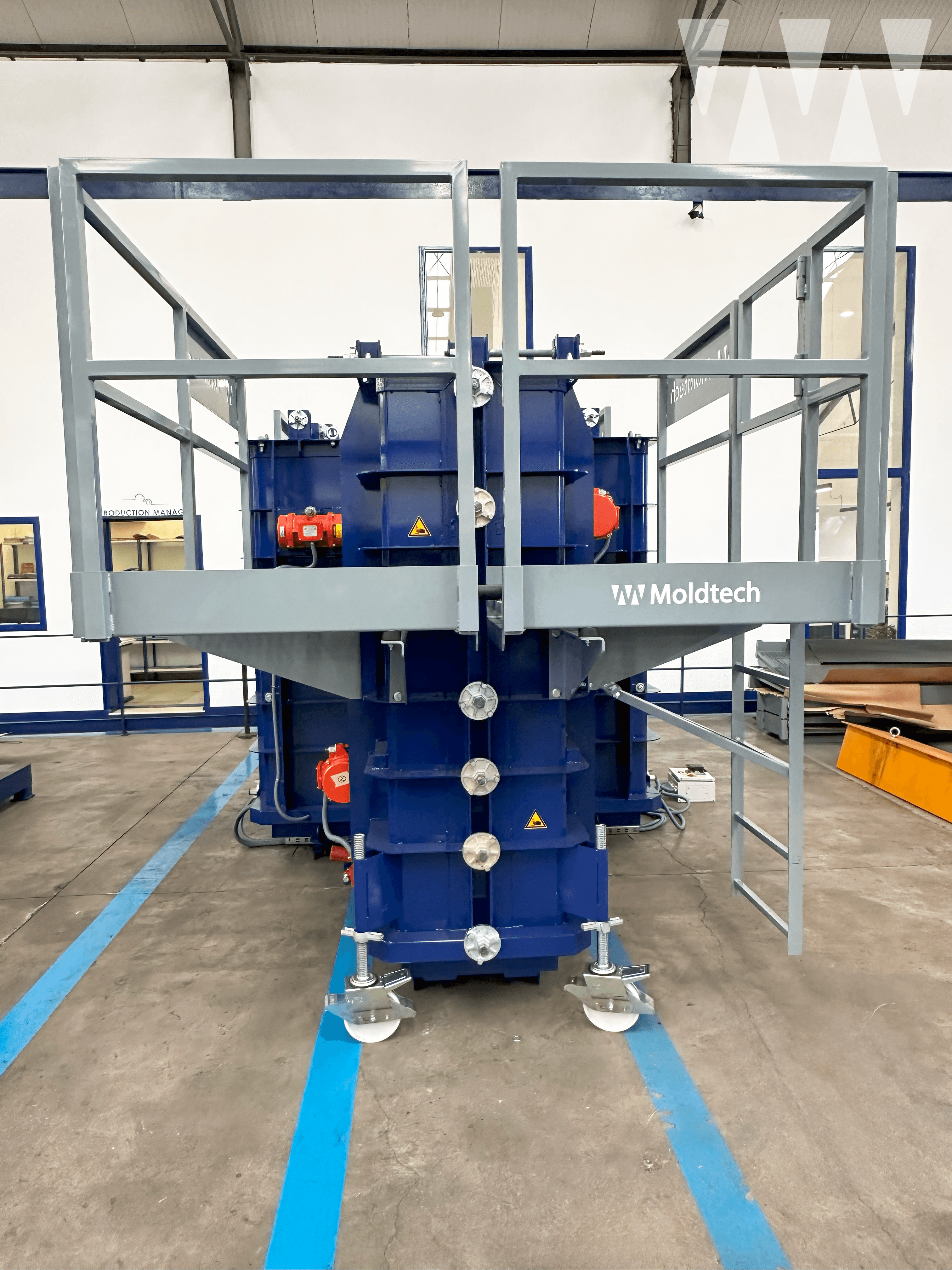

The concrete barriers, manufactured with Moldtech’s ZPX moulds, are designed to support the most demanding conditions of a railway environment. These moulds allow us to produce precast elements with high resistance to impact adverse weather conditions, guaranteeing long-term durability. Its modular design facilitates installation and allows the barriers to adapt to the specific dimensions of the project, whether at stations or crossings.

In addition to providing security, concrete barriers delimit the flow of people at stations and create a physical boundary that prevents unauthorized access to the tracks. These structures, once installed, will support the slabs that will form the platforms, offering a comprehensive solution that combines protection and functionality.

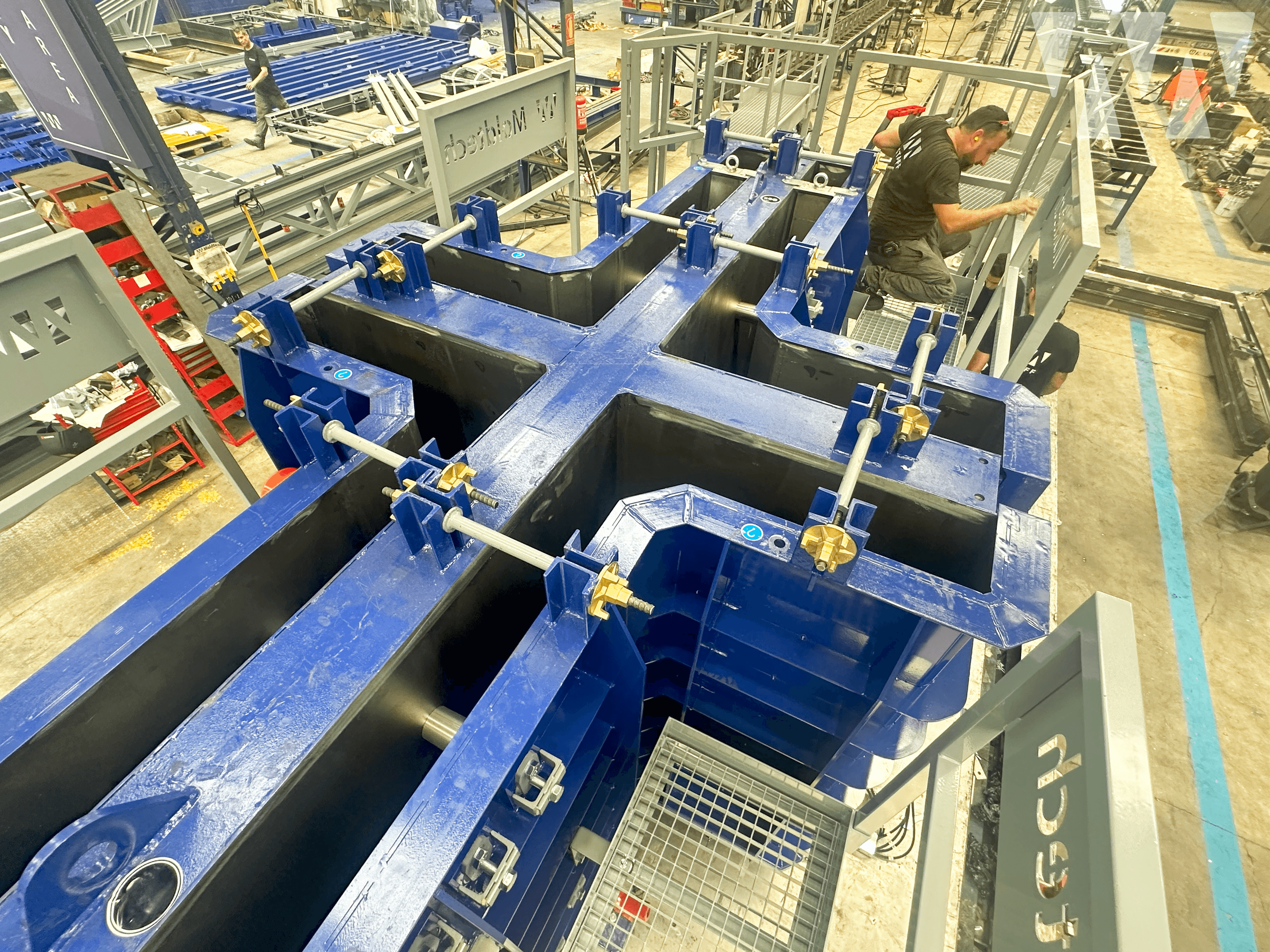

ZPX moulds are designed for the simultaneous manufacturing of four concrete pieces and produce concrete barriers of different dimensions and specifications, adapting to the needs of each railway project. These moulds incorporate technology that facilitates their handling and guarantees the quality of the final product, thus contributing to the success of the railway project in Romania.

This supply of moulds ZPX reaffirms Moldtech as a main equipment producer for modern and safe railway infrastructure in Europe. The project in Romania, which connects the Hungarian border with the Black Sea, is a work that will enhance mobility and trade in the region. The concrete barriers manufactured with Moldtech moulds will be integrated into the railway landscape, providing the security and delimitation necessary for the efficient operation of stations and tracks.

With a long history in the design and manufacture of equipment for the production of precast elements, the company offers customized solutions for infrastructure projects, and its products are present in construction sites globally.

Moldtech is proud to contribute with its moulds to the development of a safer and more advanced railway system in Eastern Europe.