Innovation in precast concrete to optimize mining infrastructure

The growth of the mining sector in Guinea continues to consolidate with the implementation of strategic infrastructure to optimize the extraction and transportation of iron minerals in the region. In this context, the incorporation of specialized precast concrete equipment is key to ensuring the efficiency, durability, and sustainability of the civil works associated with the project.

To contribute to the construction of essential infrastructure at this super mine, state-of-the-art equipment has been supplied, including:

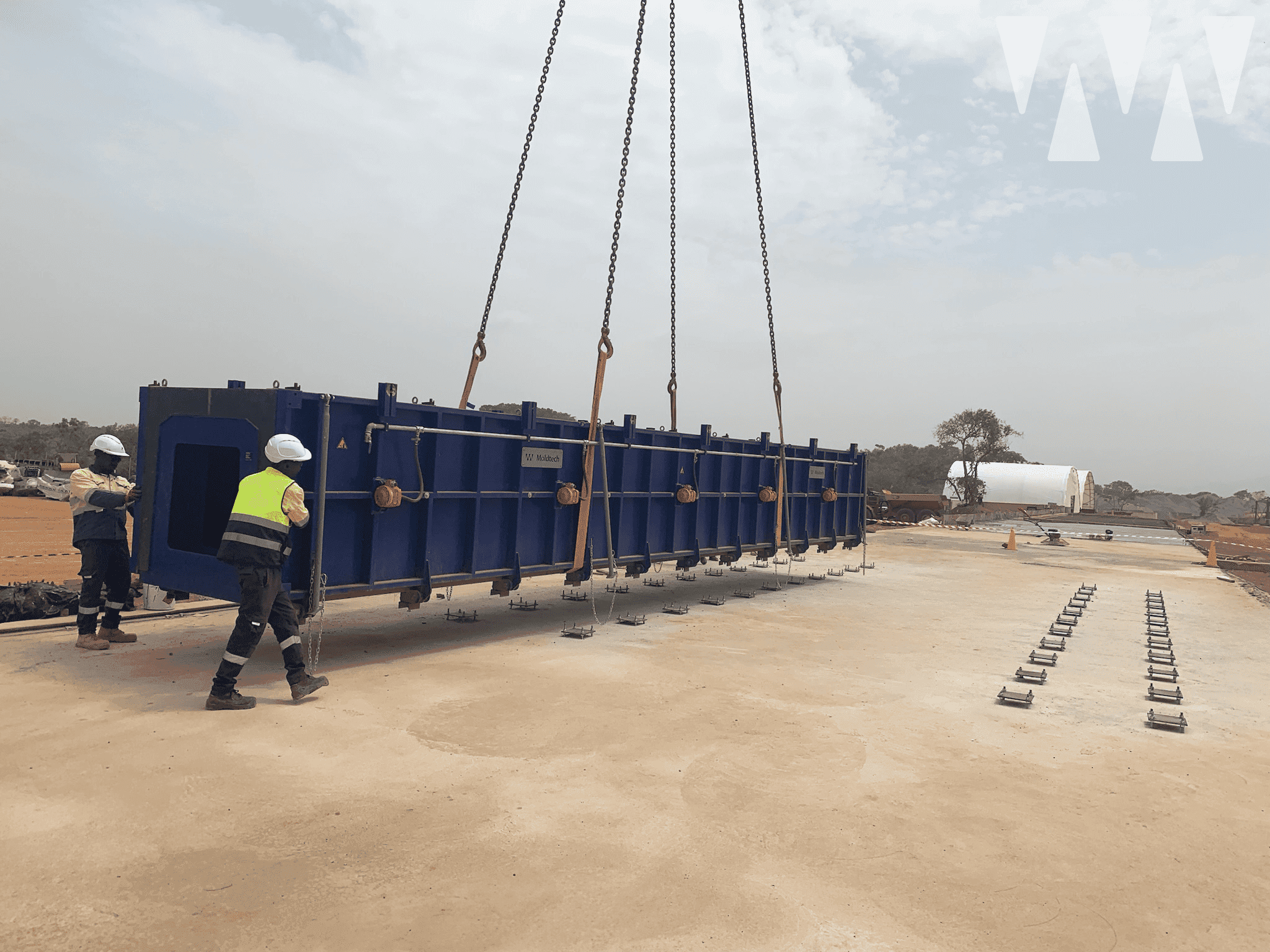

- Two moulds for U-channel with dimensions of 900×900 mm and 1200×1200 mm. These moulds allow for the manufacture of precast channels designed for efficient water management in the mine. Their implementation contributes to proper drainage, preventing sediment accumulation and reducing the impact of erosion, fundamental aspects for the sustainability of civil works in highly demanding environments.

- A fixed table for the production of precast covers for channels. This equipment allows the manufacture of concrete covers that complement the installation of U-channels, ensuring comprehensive solutions for channeling and controlling water in the mine.

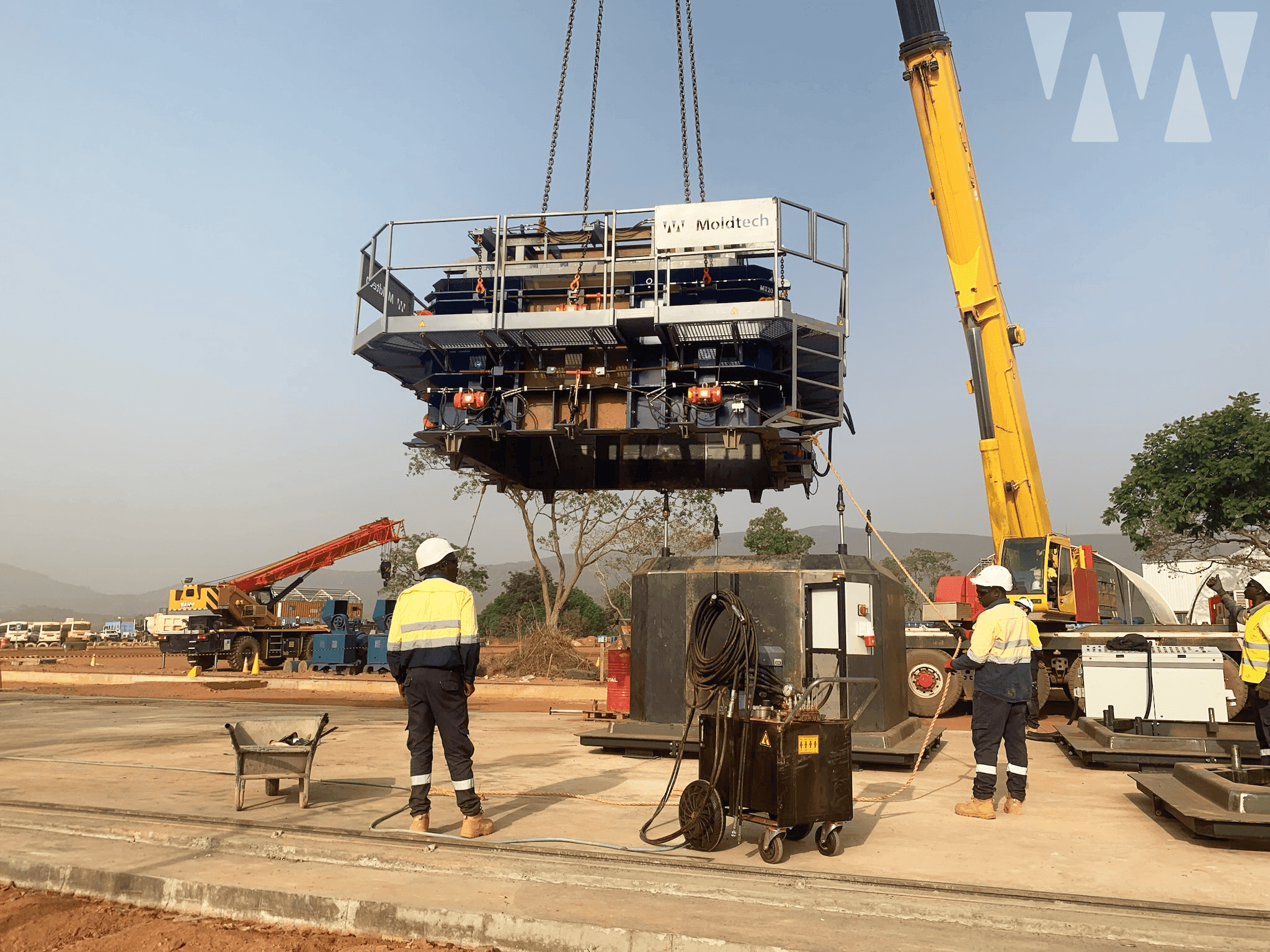

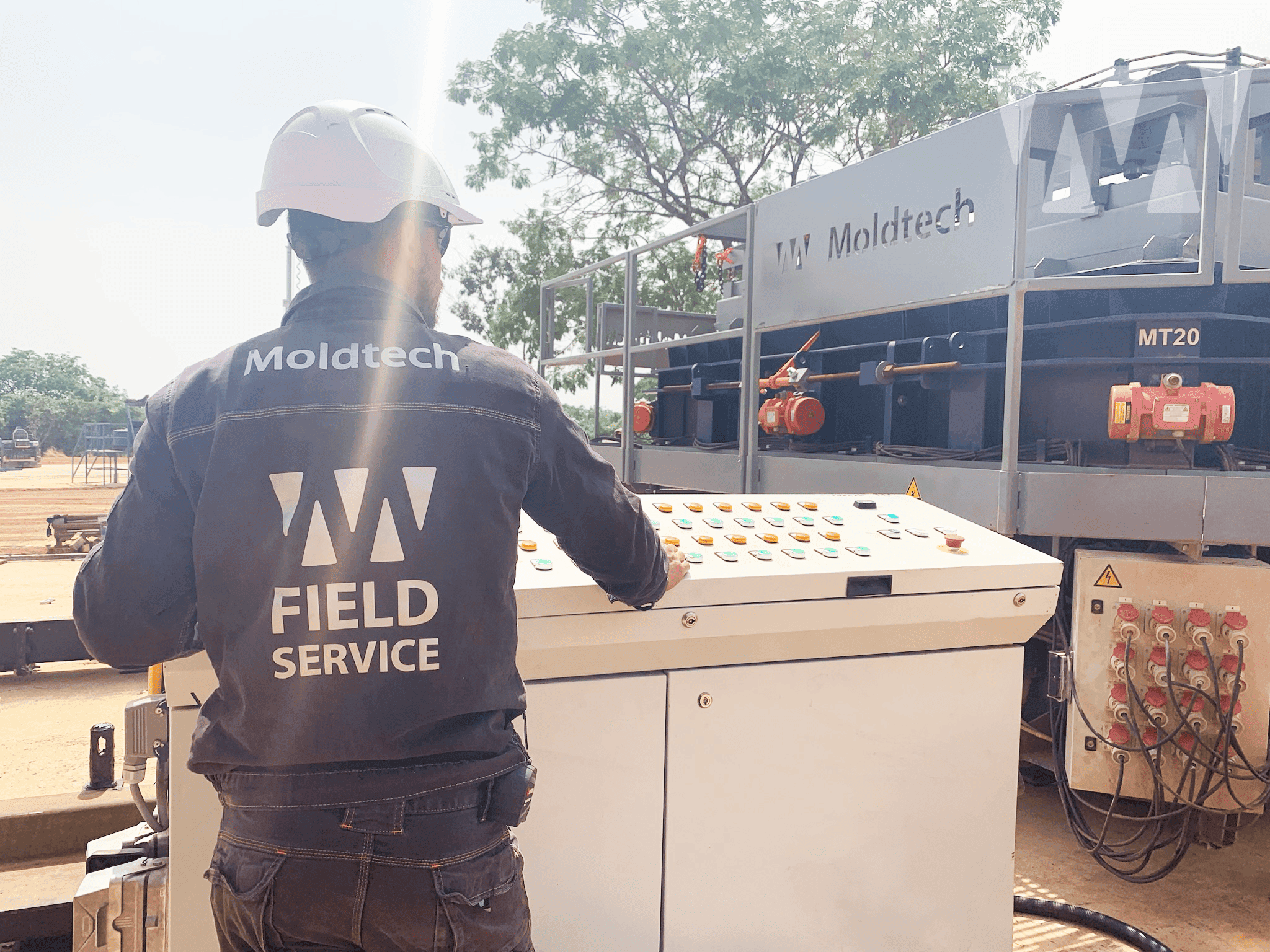

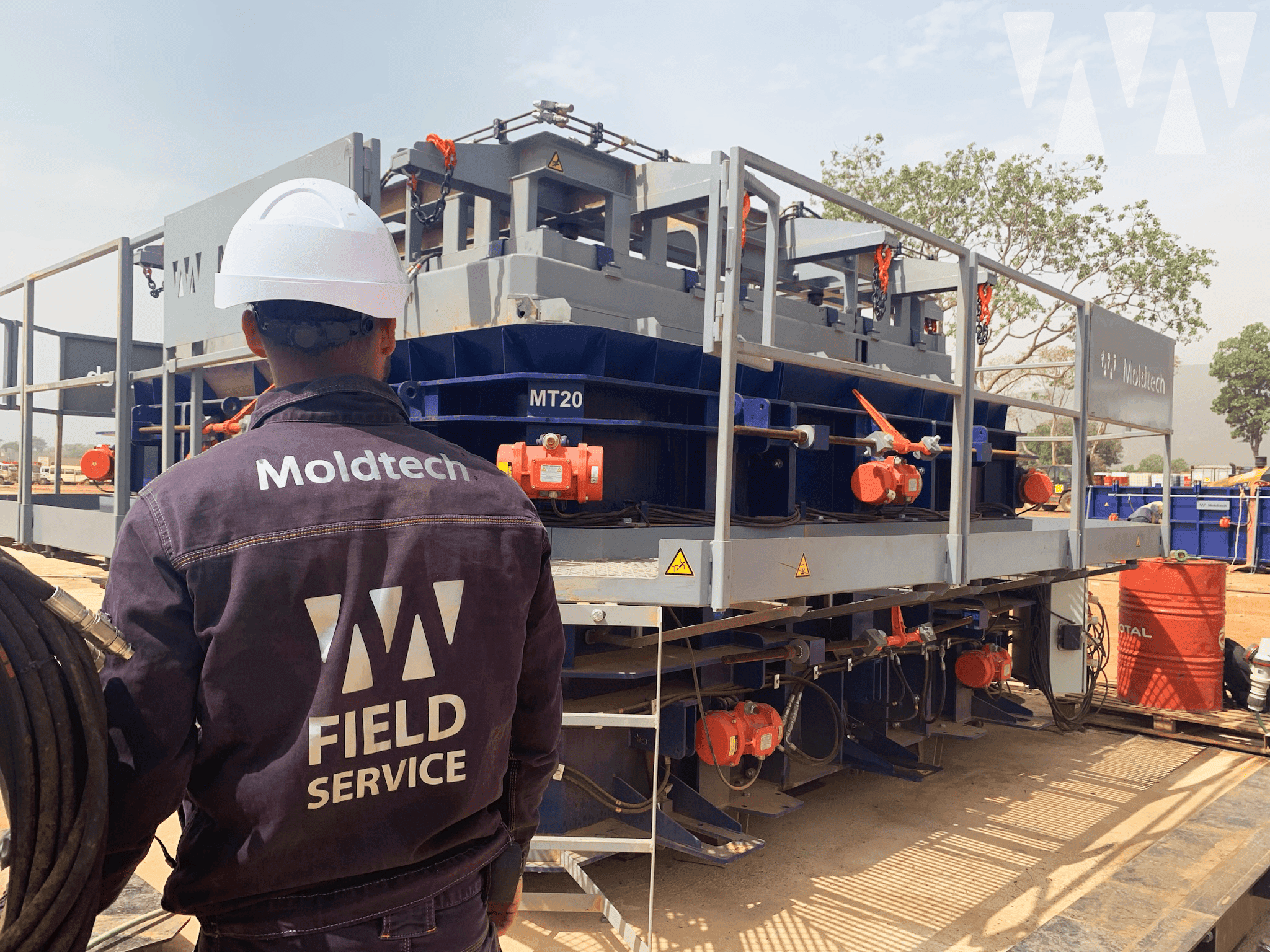

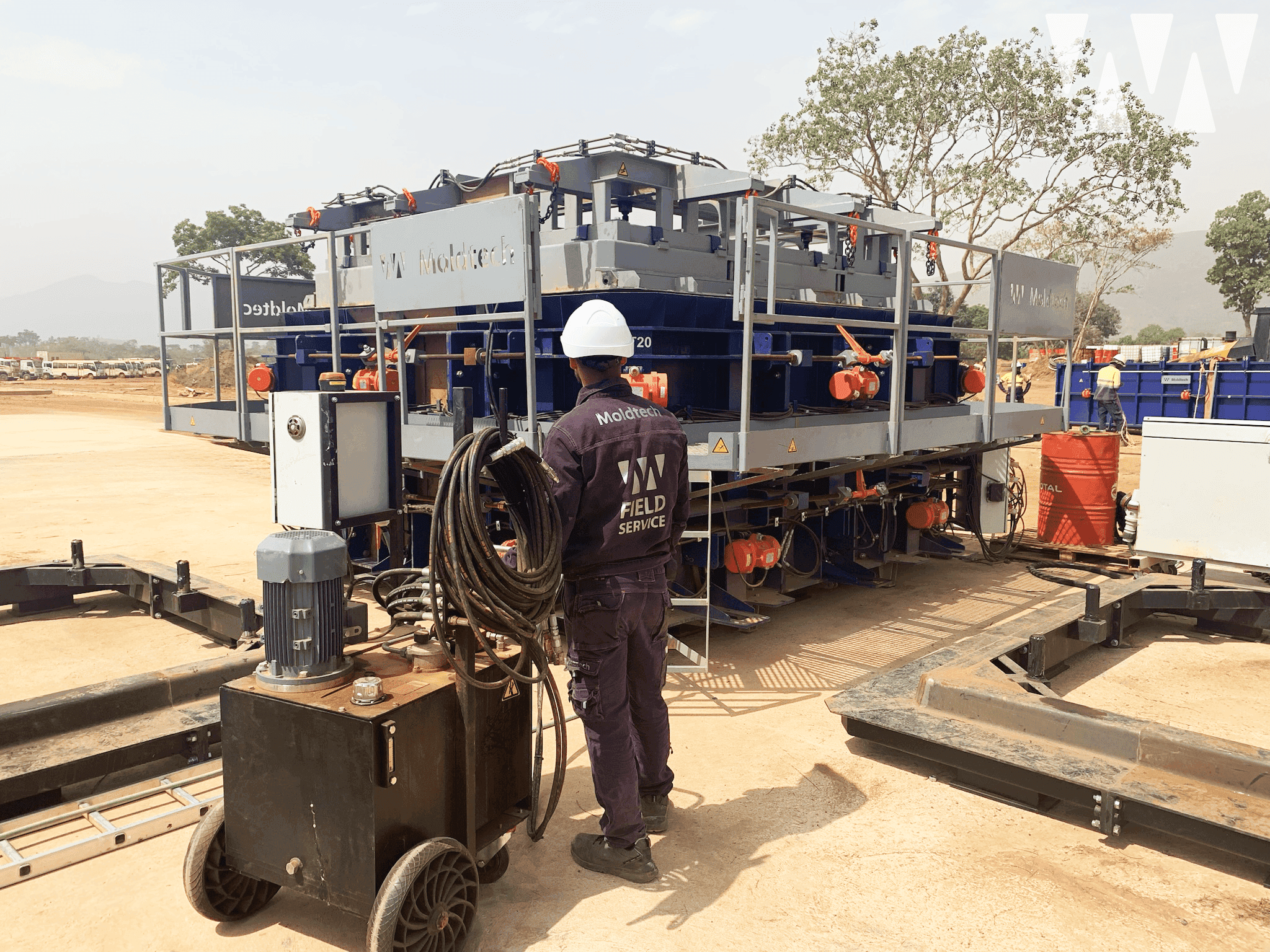

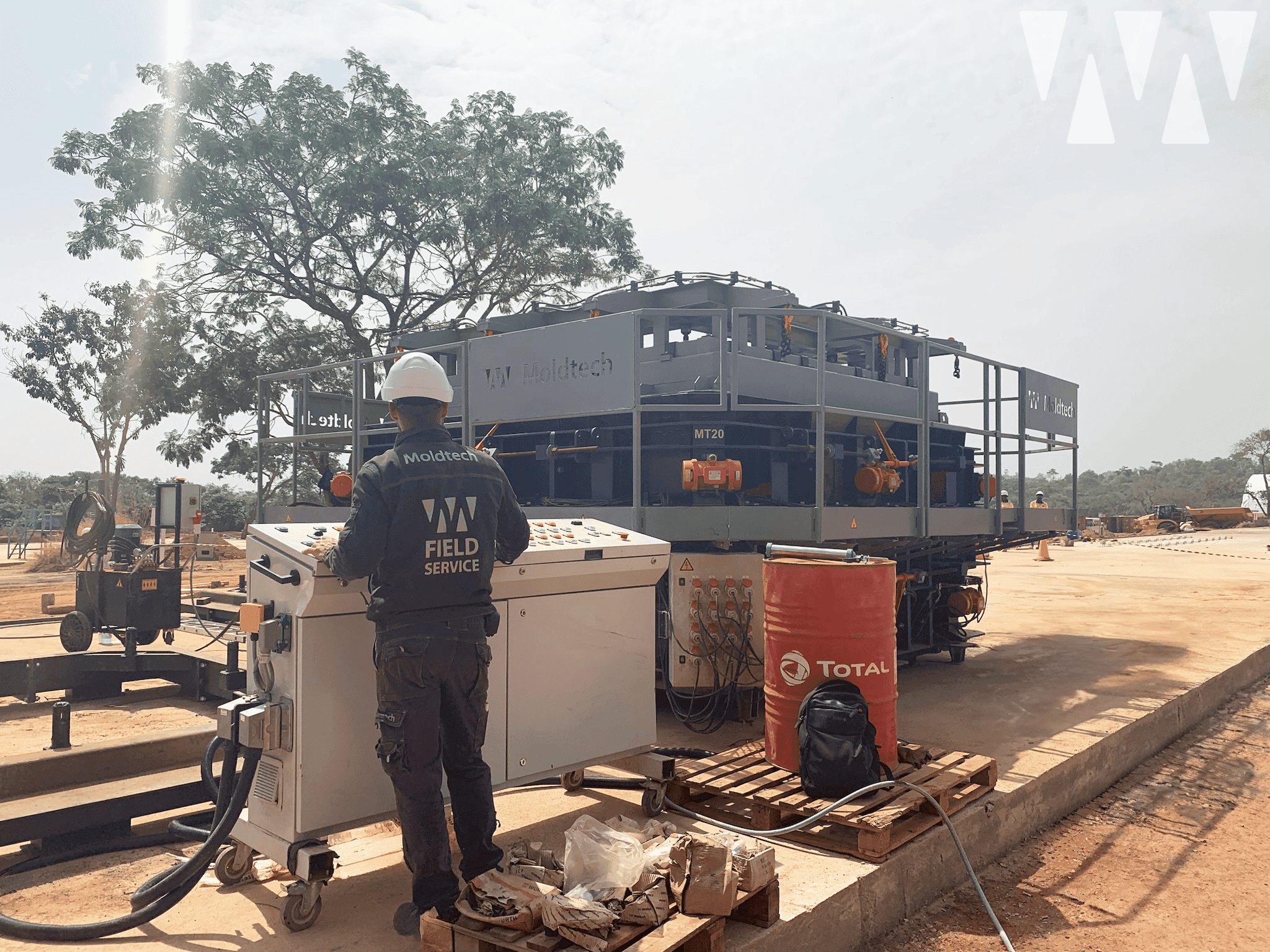

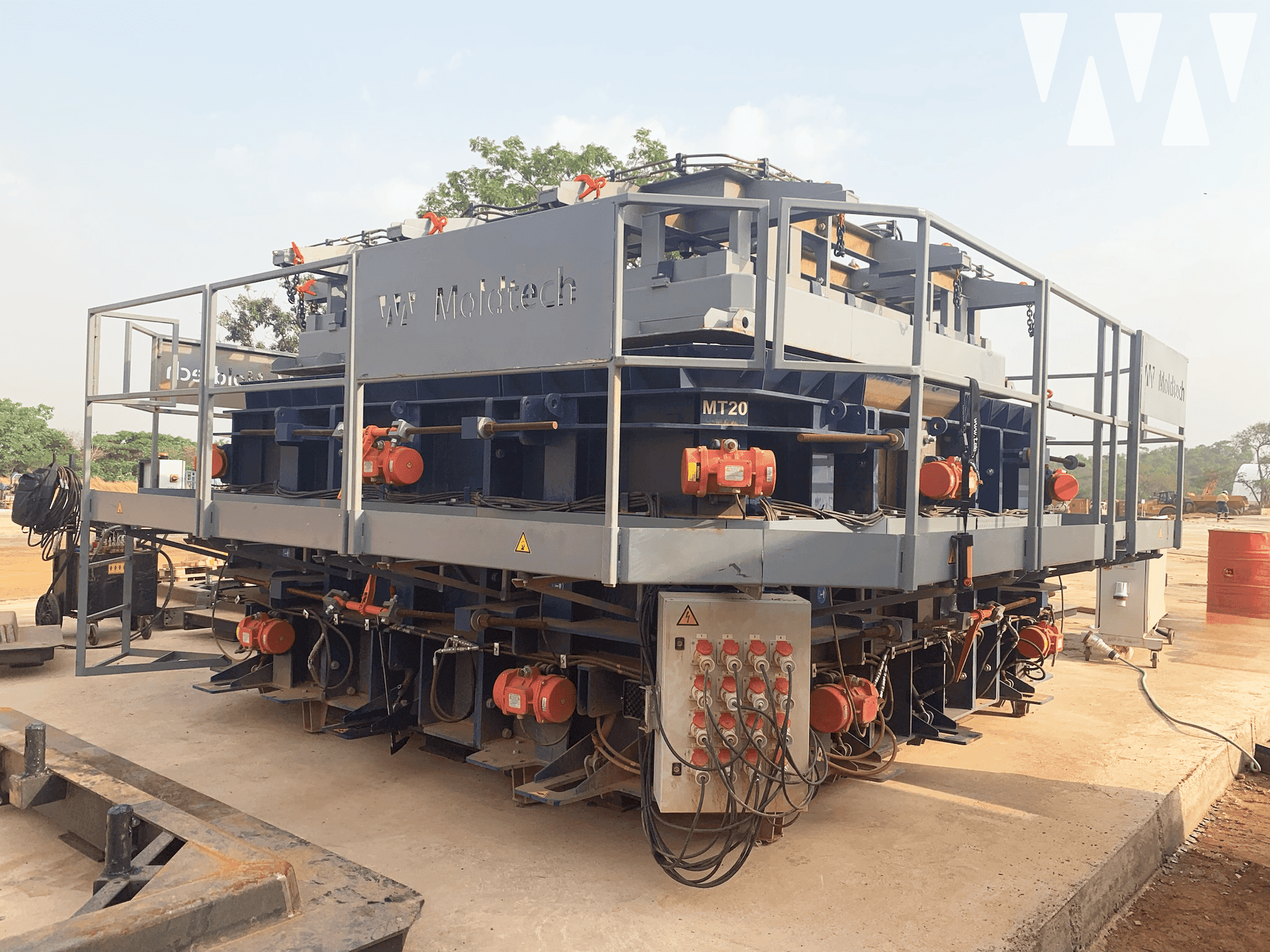

- An MT20 mould, designed for the continuous dry-cast of 2.7×2.7 m of concrete box culverts. This equipment stands out for its high productivity and its ability to operate in remote locations, allowing structural elements to be manufactured directly on-site. This not only reduces transportation costs and associated logistical challenges, but also speeds up execution times and ensures a constant supply of precast elements.

The equipment supplied will play a fundamental role in the construction of essential elements of the mining infrastructure, from drainage and channeling systems to support structures for project logistics. Optimizing these construction processes is key to ensuring the facility’s operability and safety in a highly technical environment.

This ambitious mining development requires the integration of innovative infrastructure solutions, including an extensive rail and port transportation network that will facilitate the export of iron minirals from the extraction area to maritime exit points. The implementation of advanced concrete precast technology accelerates construction times and improves the quality of the structures, ensuring they meet the highest standards of strength and durability.

The use of precast solutions not only improves the efficiency of construction processes but also reduces operating costs and minimizes environmental impact compared to traditional on-site construction methods. This is aligned with the company’s vision of promoting sustainable and optimized projects for the future of the mining sector in the region.

With this supply of specialized equipment, Moldtech reinforces its commitment to developing resilient, high-performance infrastructure at one of the most important mining operations on the African continent. The application of advanced concrete prefabrication technologies has established itself as a determining factor in the development of this mine project, providing efficient solutions for its infrastructure and contributing to the growth of the mining sector in Guinea.