At a key moment for the industrialization of the construction sector, Moldtech is consolidating its position as a world leader in precast concrete solutions, with six project assemblies underway simultaneously in France, Germany, Spain, the Caribbean, Uruguay and Guinea Conakry. This expansion reflects the company’s ability to adapt to completely different technical, cultural and logistical contexts, deploying its operations in highly complex and diverse scenarios.

ADAPTING TO EACH MARKET: FROM EUROPE TO AFRICA AND LATIN AMERICA

Moldtech’s presence in Western Europe – with ongoing commissioning activities in France, Germany and Spain – responds to markets with high technical standards, demanding regulations and a firm commitment to sustainability and process automation. In these countries, the customization of solutions and technological integration are fundamental.

In Latin America, Moldtech continues to strengthen its relationship with Uruguay and the Caribbean, where the industrialization of construction is advancing in response to the growing demand for housing and public infrastructure. Here, the company not only supplies technology, but also offers training, advice and comprehensive support.

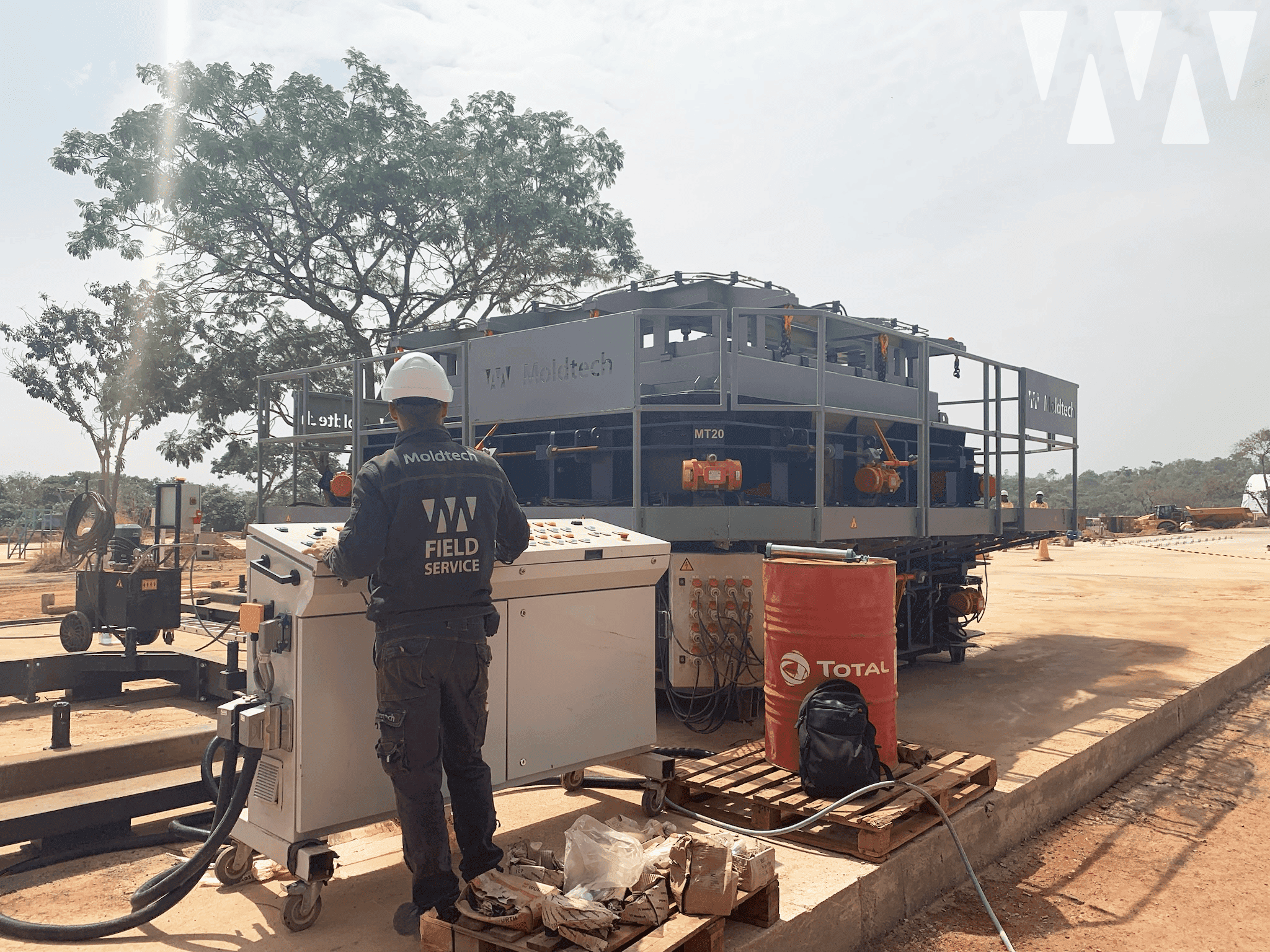

On the other hand, the project in Guinea Conakry demonstrates the company’s ability to operate in emerging markets. With limited infrastructures, these environments require robust solutions that are easy to install and maintain. Moldtech brings experience, logistical agility and a collaborative working model adapted to each local reality.

A GLOBAL, EFFICIENT AND FLEXIBLE OPERATION

Simultaneously managing six international projects requires advanced logistics and meticulous planning. Moldtech coordinates technical teams located in different parts of the world, collaborates with local partners and maintains centralized supervision from its headquarters in Seville, optimizing each stage of the process.

This deployment demonstrates the structural, technical and human capacity of the company, which is capable of serving multiple markets with completely different realities, overcoming language barriers, adapting to local regulations and responding with high added value solutions.

SOLUTIONS FOR ALL SECTORS OF PRECAST

Ongoing projects cover the three main sectors of prefabrication: residential, industrial and civil works. Moldtech supplies advanced technology equipment adapted to each application and type of construction:

▸ RESIDENTIAL SECTOR

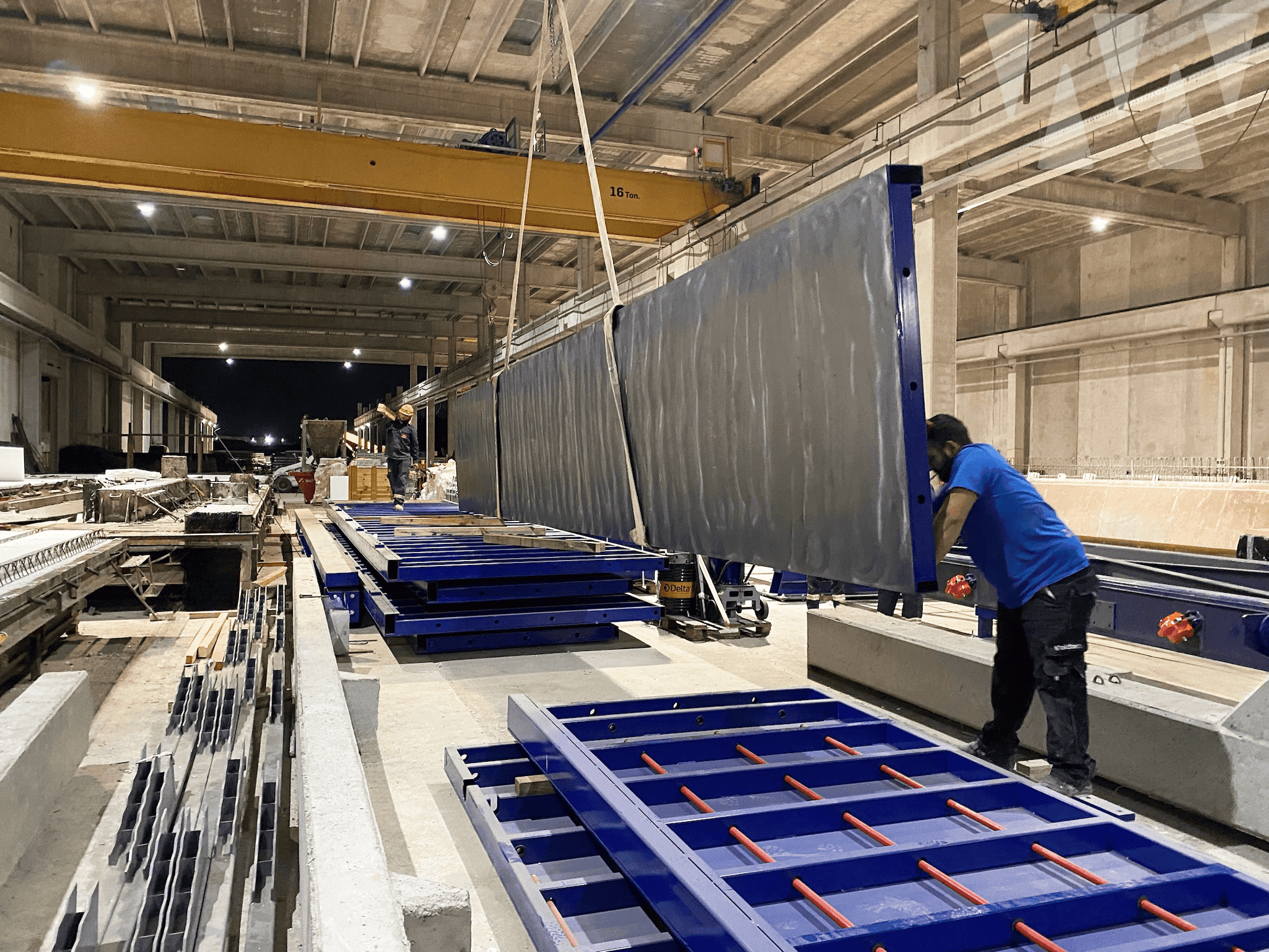

- Tilting tables: Designed for the production of vertical precast panels, these tables allow for efficient panel removal, incorporating vibration and heating systems to accelerate concrete curing.

- Column Moulds: Versatile solutions to produce pillars of different cross-sections, heights and with multiple bracket options, ideal for building structures.

▸ INDUSTRIAL SECTOR

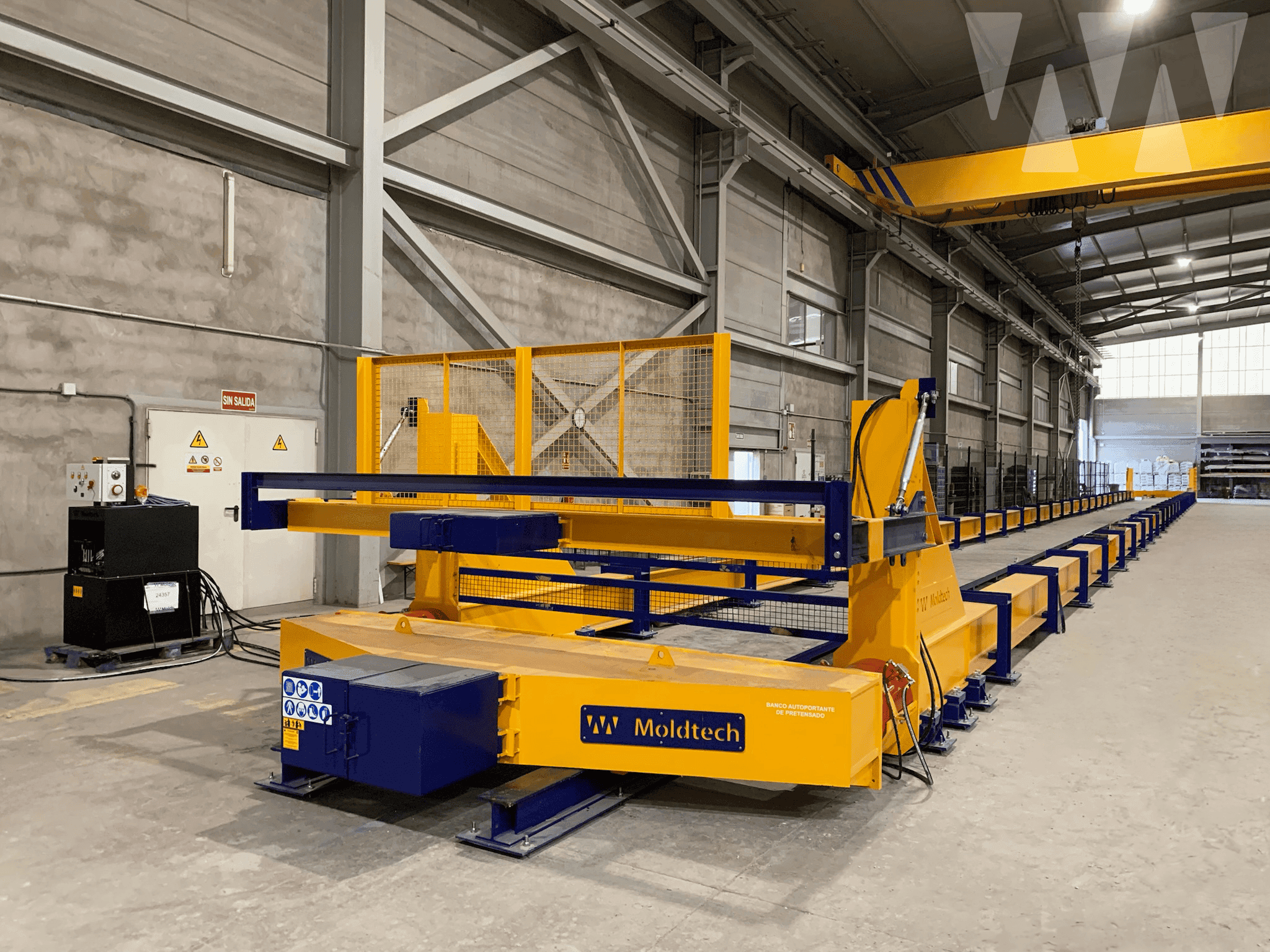

- Self-supporting beds lateral forms for I-beams: They allow the production of prestressed beams without the need for external foundations, facilitating an agile and modular assembly.

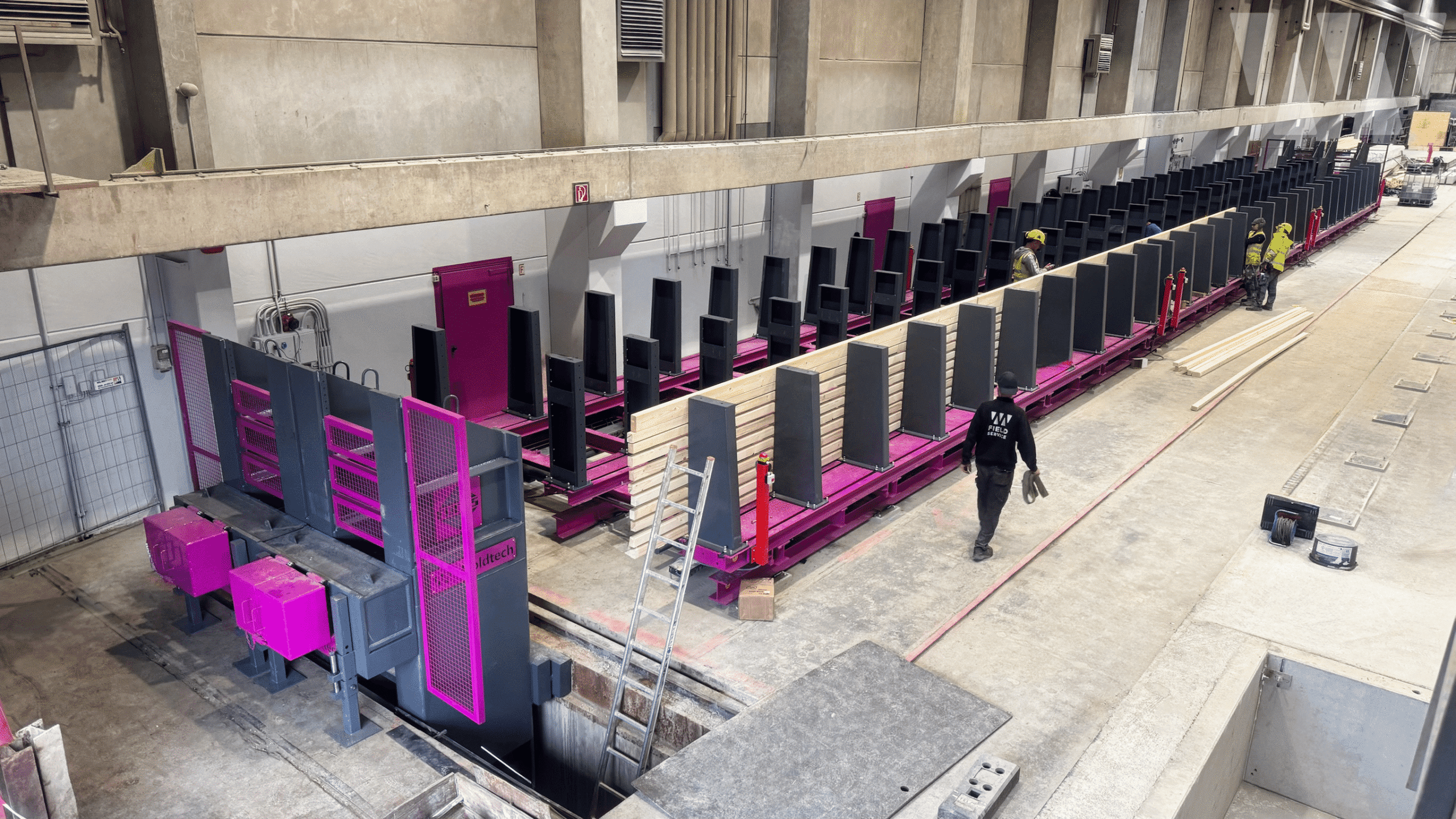

- Battery Moulds for Prestressed Joist beams: Perfect for series production, especially used for roofs of industrial structures.

▸ CIVIL WORKS SECTOR

- Mould MT20 for box-culverts: A highly demanded solution for hydraulic infrastructures, drains and subways, with wall thicknesses of 200-250 mm and poured in semi-dry concrete.

- Gutter moulds: With side opening, they allow the manufacture of customized concrete gutters for sanitation, water drainage and drainage works.

- AASHTO Beam Sides: Designed for the production of AASHTO type beams used in the construction of bridges and road infrastructure.

▸ AUXILIARY AND SPECIAL EQUIPMENT

- Troweling and leveling machines: Complementary equipment to optimize the quality of the concrete finish.

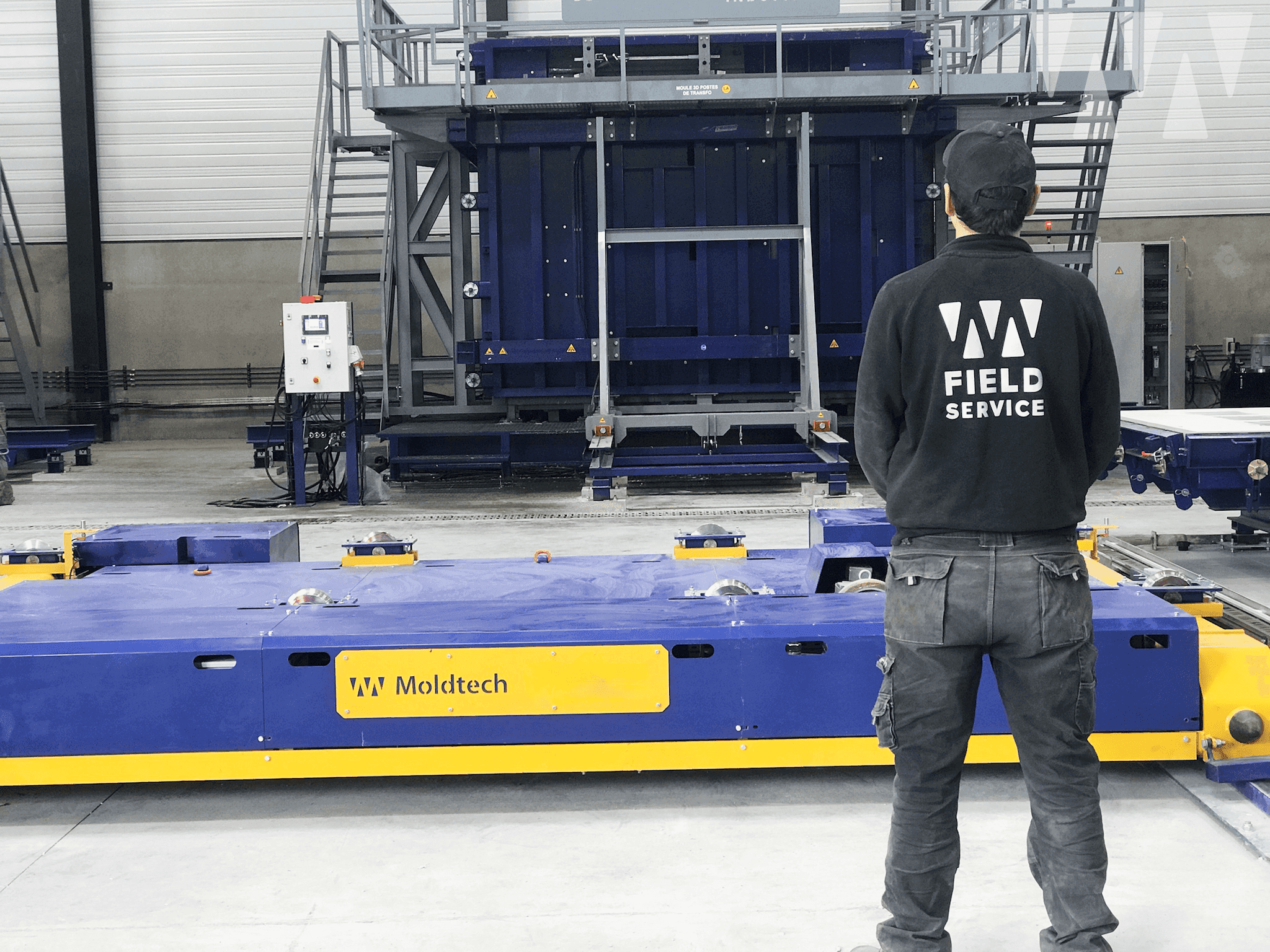

- 3D Moulds for Transformer Houses: Complex moulds that allow the manufacture of prefabricated volumetric structures, such as electrical substations.

With this new wave of installations, Moldtech confirms its leadership as a global provider of precast concrete solutions. Beyond the product, it offers a vision, a methodology and a commitment to the development of industrialized construction worldwide.