Moldtech supplies equipment for a new precast factory after two years of development.

Moldtech, a company specialised in solutions for the precast concrete industry, has completed a project in Romania in collaboration with one of the leading construction companies in the region. The project, which spanned over two years, aimed at the development and implementation of essential infrastructure for the construction of industrial buildings. The supply provided by Moldtech includes:

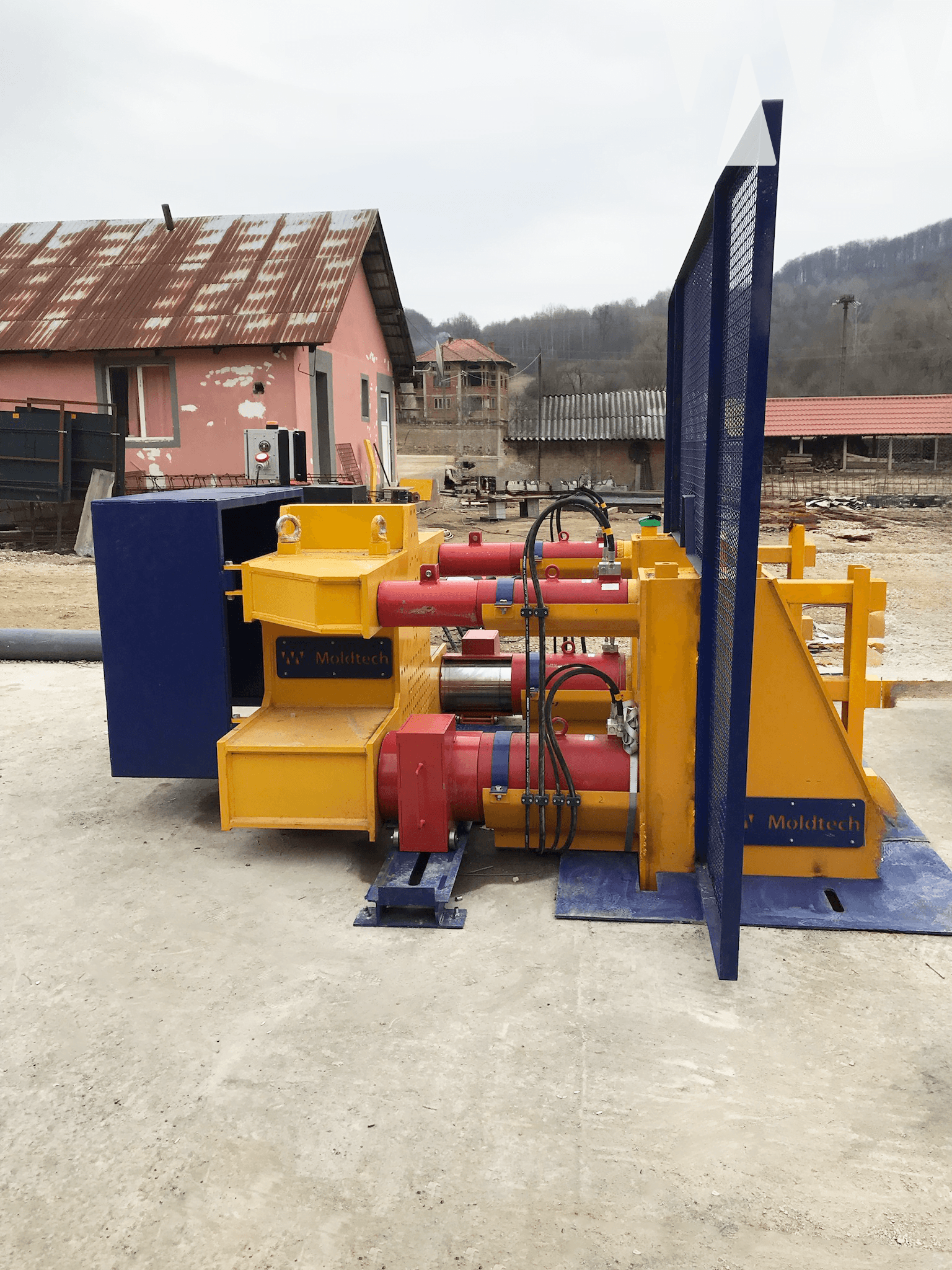

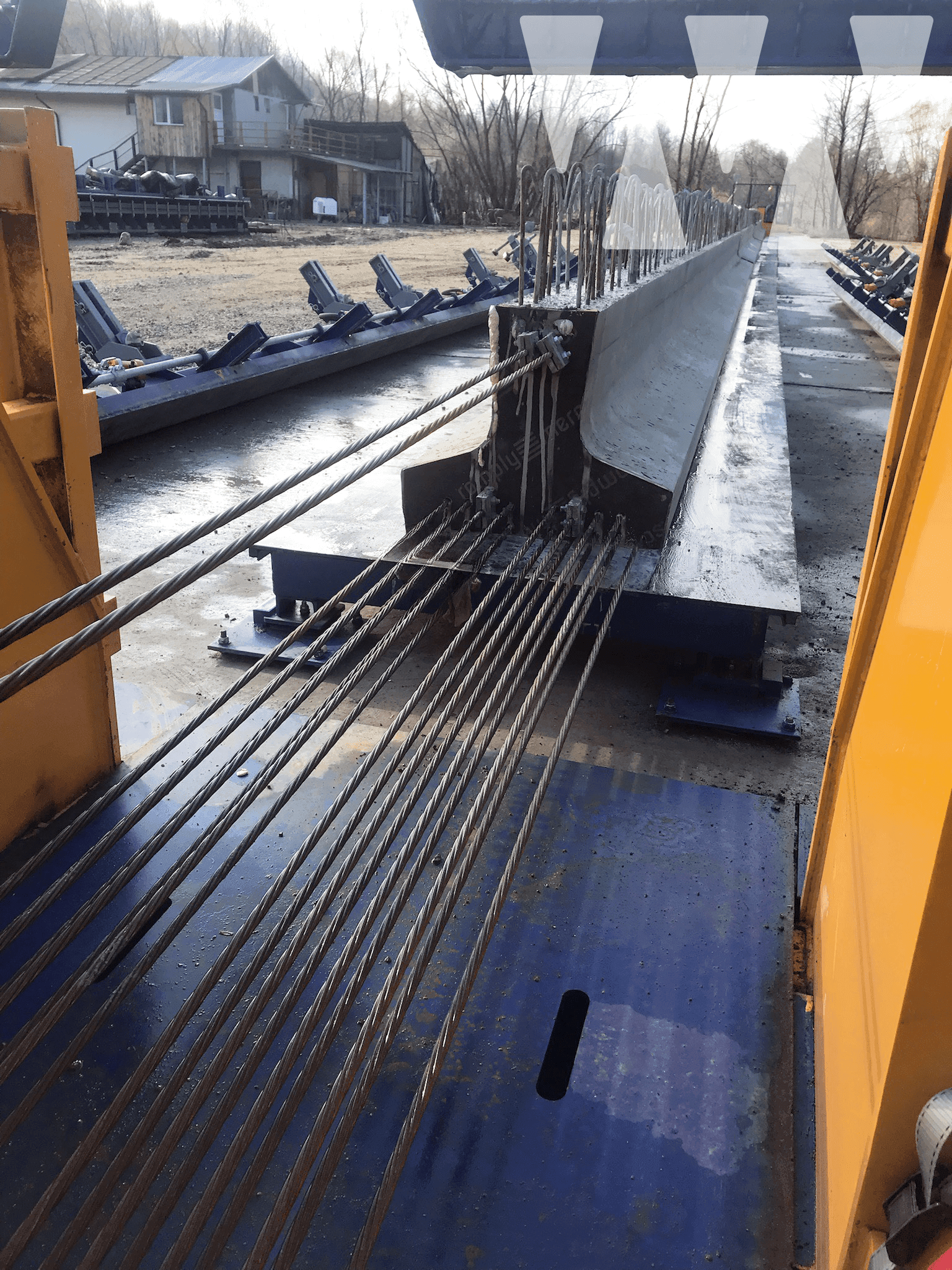

- Universal Casting bed systems, equipped with two prestressing heads of up to 450 tones and intended for use in foundation pits.

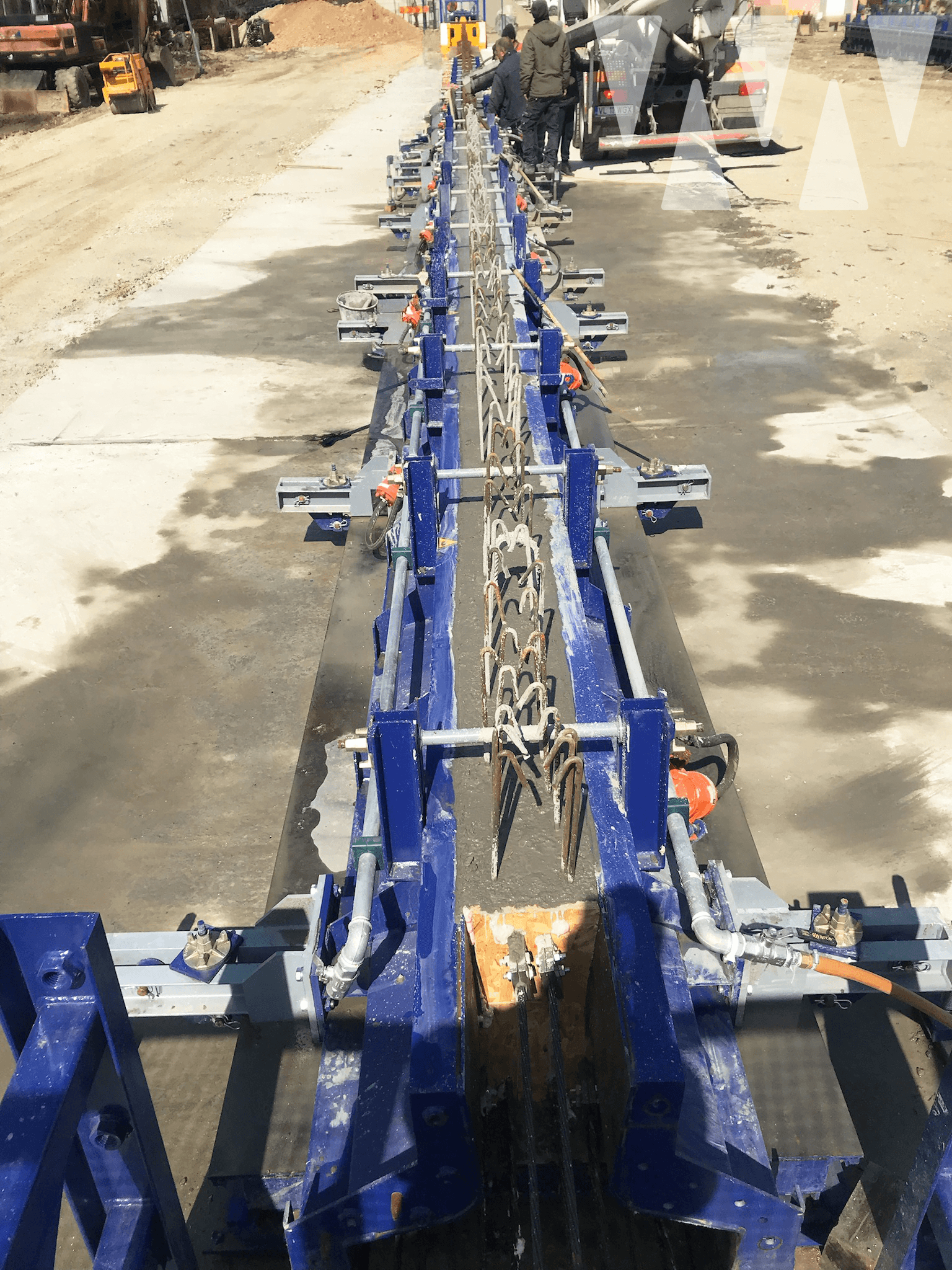

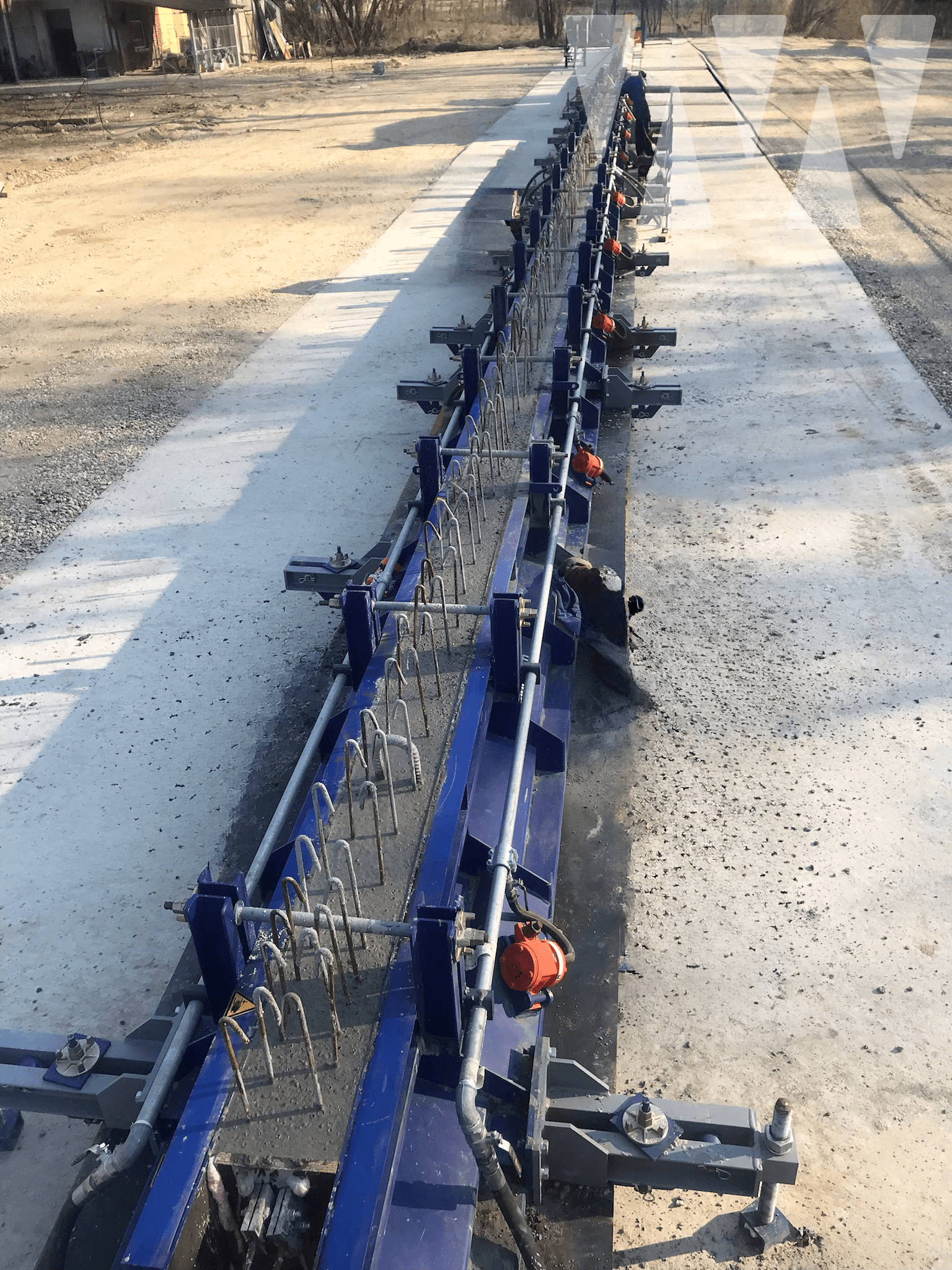

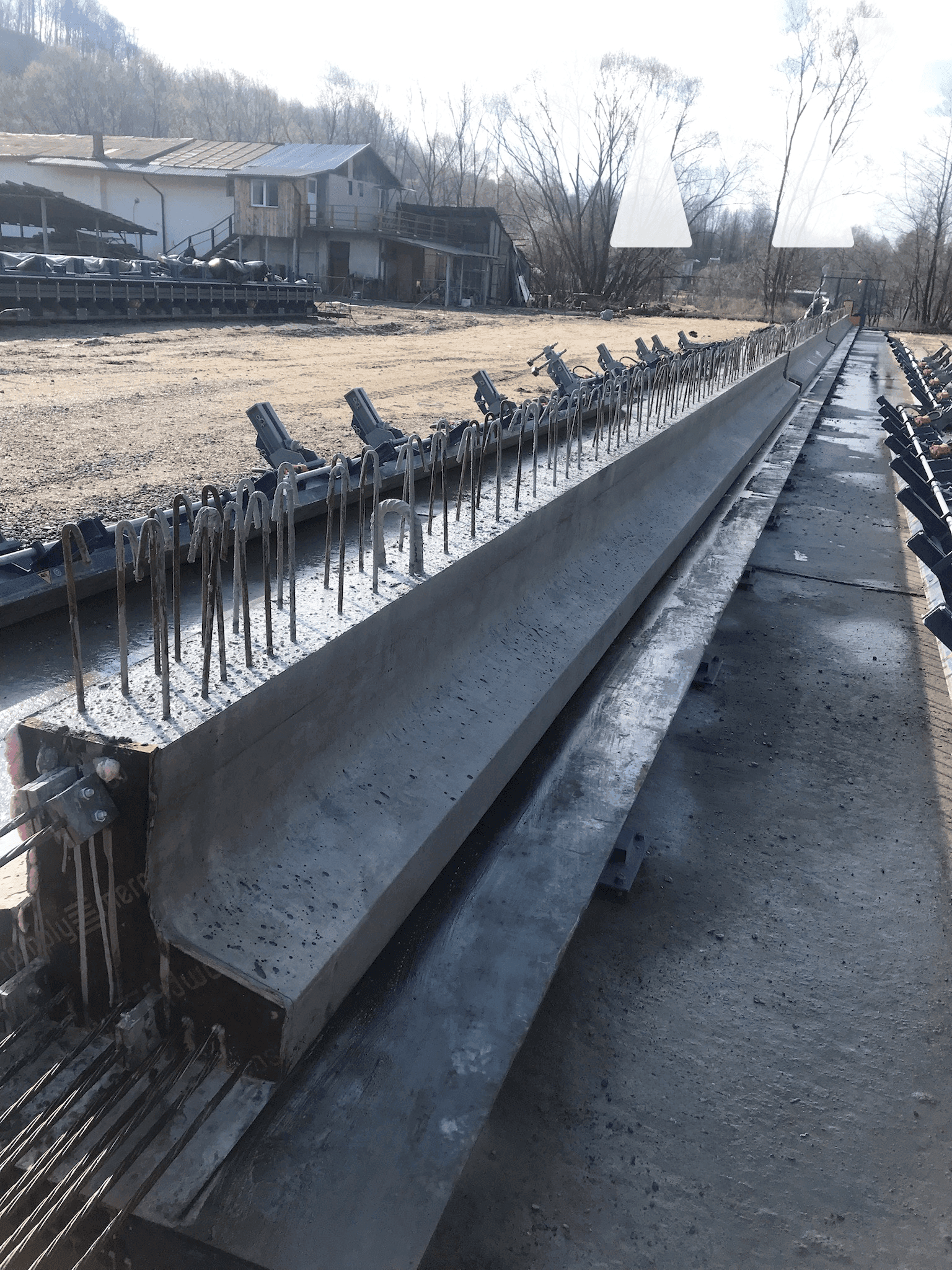

The manufacturing of prestressed elements is carried out on universal casting beds, equipped with side moulds and a prestressing system that includes detensioning heads and hydraulic equipment. The prestressing heads are designed according to the maximum amount of tension required to be resisted, consisting of an active tensioning head and a passive one. The universal casting bed, designed with adjustable supports and sealing joints, allow for varying the height and section of the beams, ensuring an effective seal. Additionally, they can incorporate floor heating to facilitate rapid curing of the concrete.

Types of Delivered Side Moulds:

- Mould for dalla beams.

- Mould for T beams.

- Mould for I girders.

The side moulds offer advanced functionalities for the manufacturing of concrete pieces, including manual or hydraulic opening/closing systems, modular height adjustment, and extension options to vary the length and height of the pieces. They are designed for easy fixation to the support structure and feature quick locking and closing systems to ensure rigidity. Furthermore, they incorporate a pneumatic vibration system with independent vibrators to optimise the compaction of the concrete, facilitating the production of armed or prestressed elements with optimization and flexibility.

These components are crucial for the creation of prefabricated structures, which are widely used in industrial construction for their quality and durability.

The collaboration between Moldtech and the Romanian construction company underscores the technical approach and precision required for the successful execution of projects of this magnitude. Moldtech, with its experience in creating moulds and equipment for the precast concrete, has demonstrated its ability to meet complex technical specifications and adapt to the needs of significant industrial projects.

The completion of this project in Romania represents a notable example of the practical application of advanced solutions in the field of concrete prefabrication. Through this effort, Moldtech reinforces its position as a leading provider of technology and equipment for the precast construction industry, meeting the technical and operational demands of large industrial projects.