60 Meter Tilting Table for Industrial Façade Panels

Moldtech continues to consolidate its position as a leader in precast concrete solutions, having recently completed the installation of a fourth tilting table at our client’s facility in Monterrey, Mexico. This customer, renowned for the high quality of its products and for having a registered precast brand name, has once again placed its trust in Moldtech to expand its production capacity.

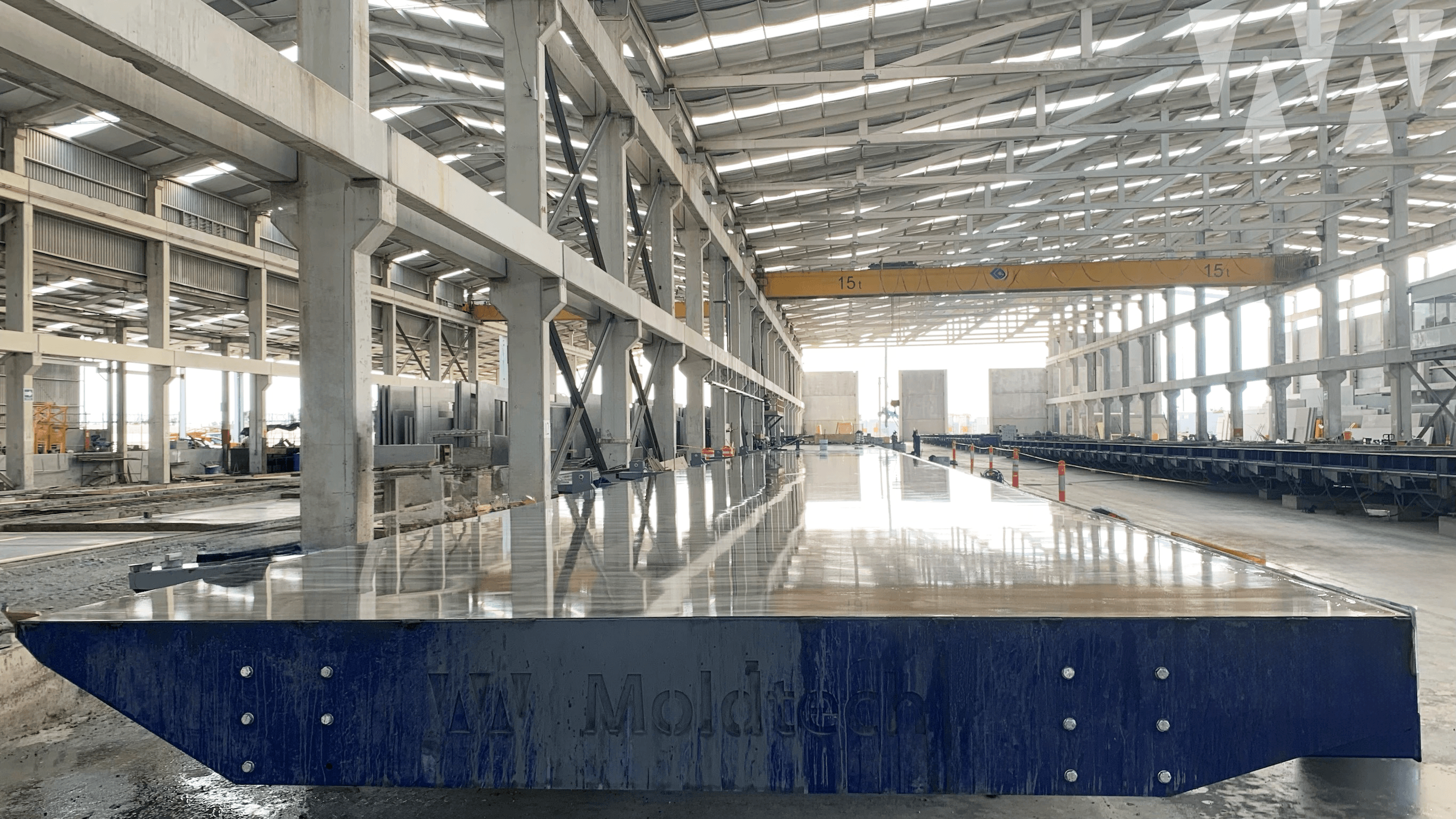

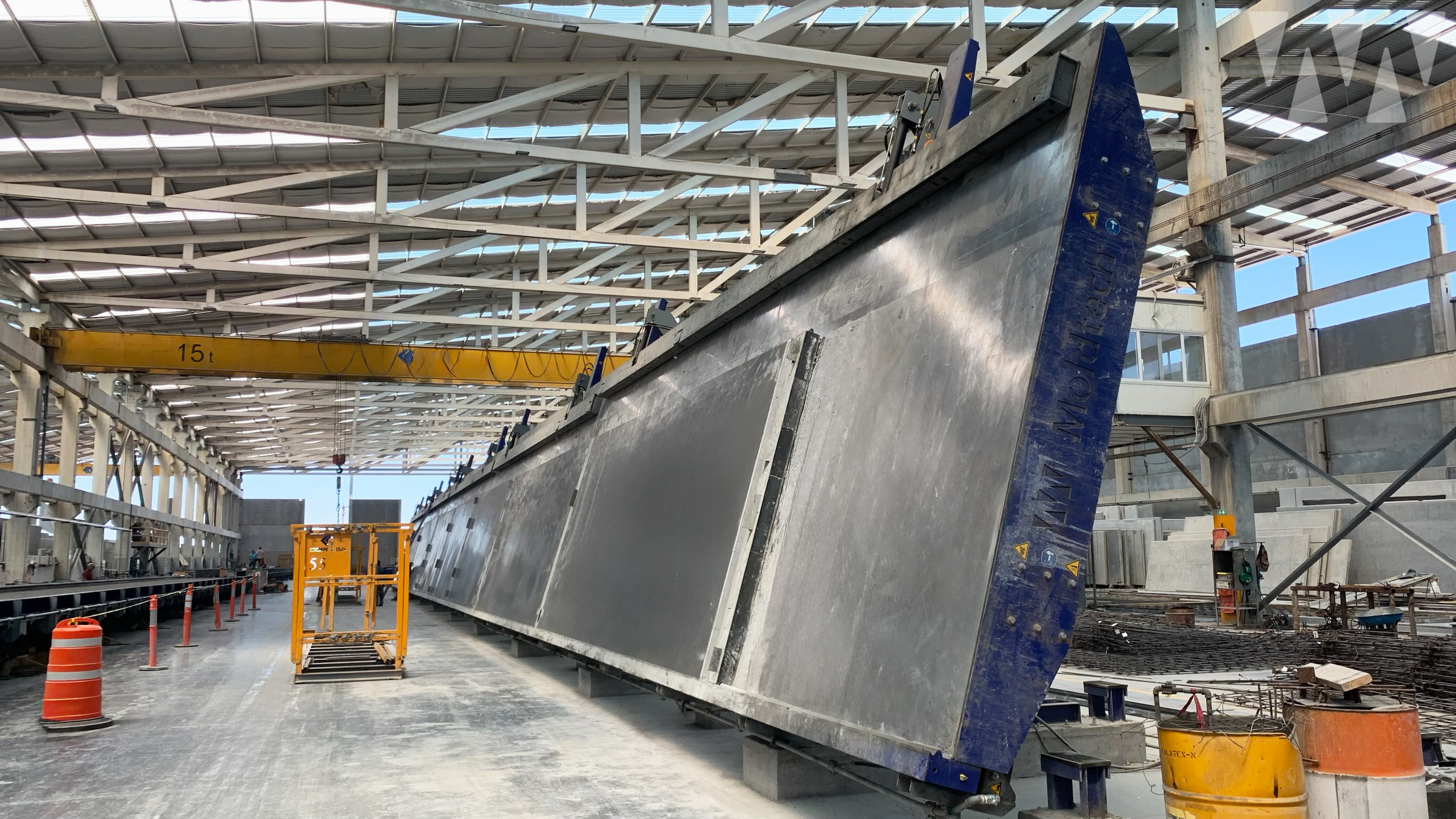

The new tilting table, designed specifically for the production of non-prestressed precast concrete panels, stands out for its imposing dimensions: a total length of 60 meters and a width of 4 meters providing a total casting surface of 240m2. The table consists of a fixed frame with supports anchored to the foundation and has a tilting angle of 74º, which facilitates a stress-free removal of the casted panels.

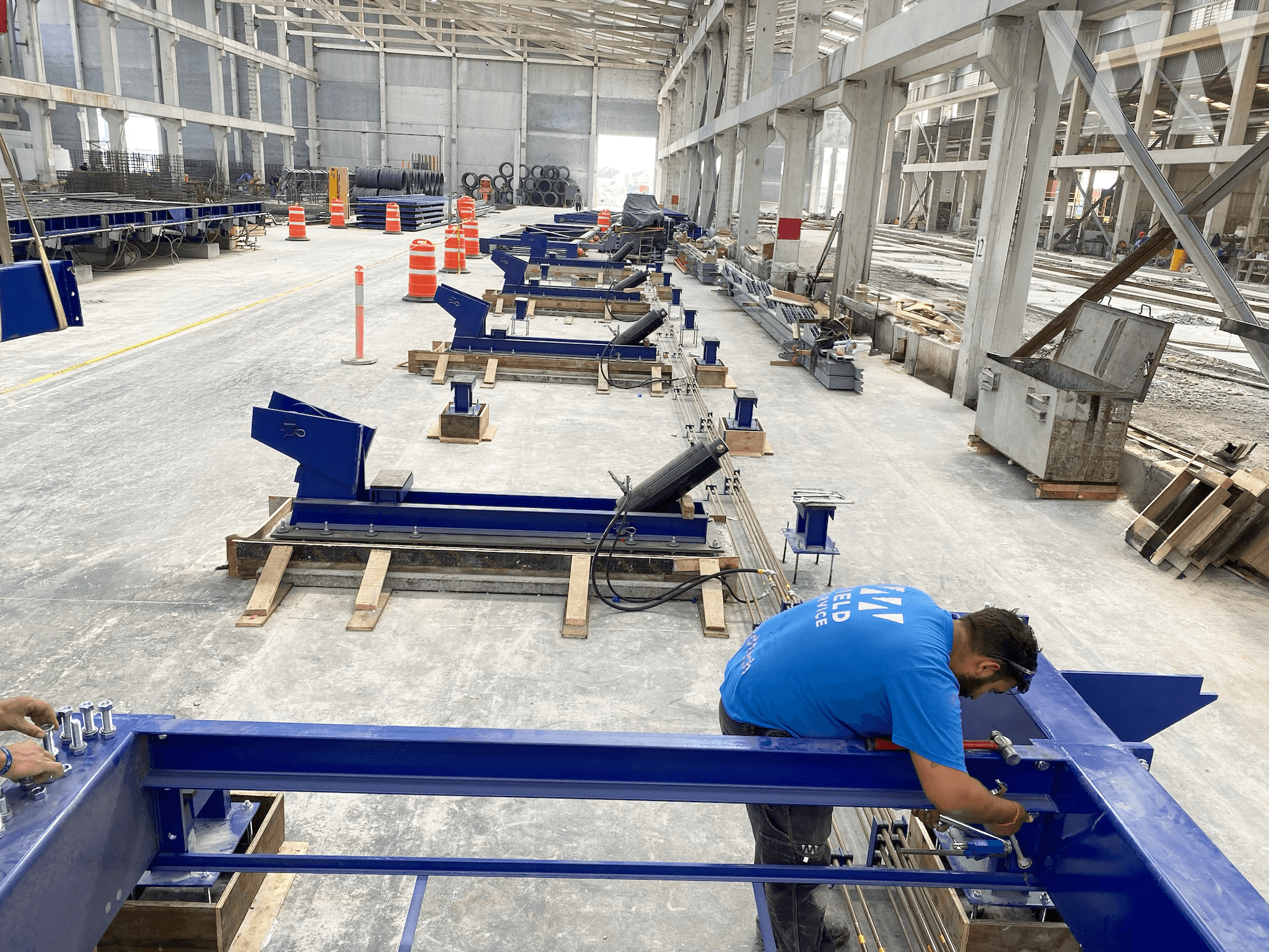

The tilting movement of the table, together with the movement of the shutters to adjust the panel height and panel thickness, is managed by hydraulic cylinders connected to a hydraulic control unit, controlled from a main cabinet and also by remote control.

Shuttering

The bottom and top shutters are adjustable in height, allowing the production of panels with a thickness between 100 and 250mm with exact measurements and perfect finishes. The hydraulic top shutter, equipped with a removable tongue and groove profile and a frictionless moving system allows a quick and effortless adjustment of the panel width. In addition, 10 magnetic shuttering chassis units have been supplied to increase the options for panel width variation and thereby the versatility of the production.

Moldtech has also carried out an exhaustive polishing of the table surface, guaranteeing a top quality finish on each panel produced, regardless of the type of concrete used. In addition, this table is equipped with a pneumatic vibration system and pre-installation for hot water or steam heating, ensuring adaptability to various production conditions.

This latest delivery completes a project that began in 2021 with the installation of two 60-meter tables. The third table was delivered in 2023, and now, with the addition of the fourth table in August this year, our customer in Monterrey has the largest panel production capacity in the entire region, with a daily capacity of 1,920 square meters with 2 production cycles in 24 hours.

The trust placed in Moldtech has been key to our client’s positioning as a leader in panel production in Mexico. This project is a testament to Moldtech’s commitment to innovation and excellence, reaffirming our position as a strategic partner in the precast concrete industry.