Moldtech continues to be at the forefront of more efficient and sustainable construction, this time presenting

a new high productivity system for prestressed joist beams

The prestressed joist beam is a structural concrete element used for precast concrete floors or slabs. The joist-and-vault slab is a construction method that integrates the load-bearing features of the prestressed joist beams and the lightening features of the concrete blocks. The system, which has been designed mainly for residential construction, allows its application also in civil and commercial projects, due to its low weight, it is possible to cover large spans without significant increases in the thickness of the compression layer.

- This system is a simple construction method which does not require very experienced labors or heavy machinery to be used.

- The system is suitable for building our own homes.

- Possibility of purchasing joist beams and to stock them in standard lengths (usually with steps of 20 cm from minimum lengths).

- The slabs where the vault system is used, especially those which are produced with polystyrene material, offer good thermal and acoustic insulation qualities.

- When using this system, the safety and the quality of the product is guaranteed, because these precast concrete elements are verified under strict quality and tracing tests and controls.

- This system has a very low cost per square meter, considering that up to 70% less labor time will be required for the installation of these products. At the same time, we will save on formworks.

- Seismic resistance. The mentioned slabs will collaborate with the rest of the structural elements included in this construction, and the system will behave like a rigid diaphragm which will absorb the shear forces of the earthquake.

CASTING OF PRESTRESSED JOISTS BEAMS ON A MOLDTECH SELF-REACTING BATTERY TABLE

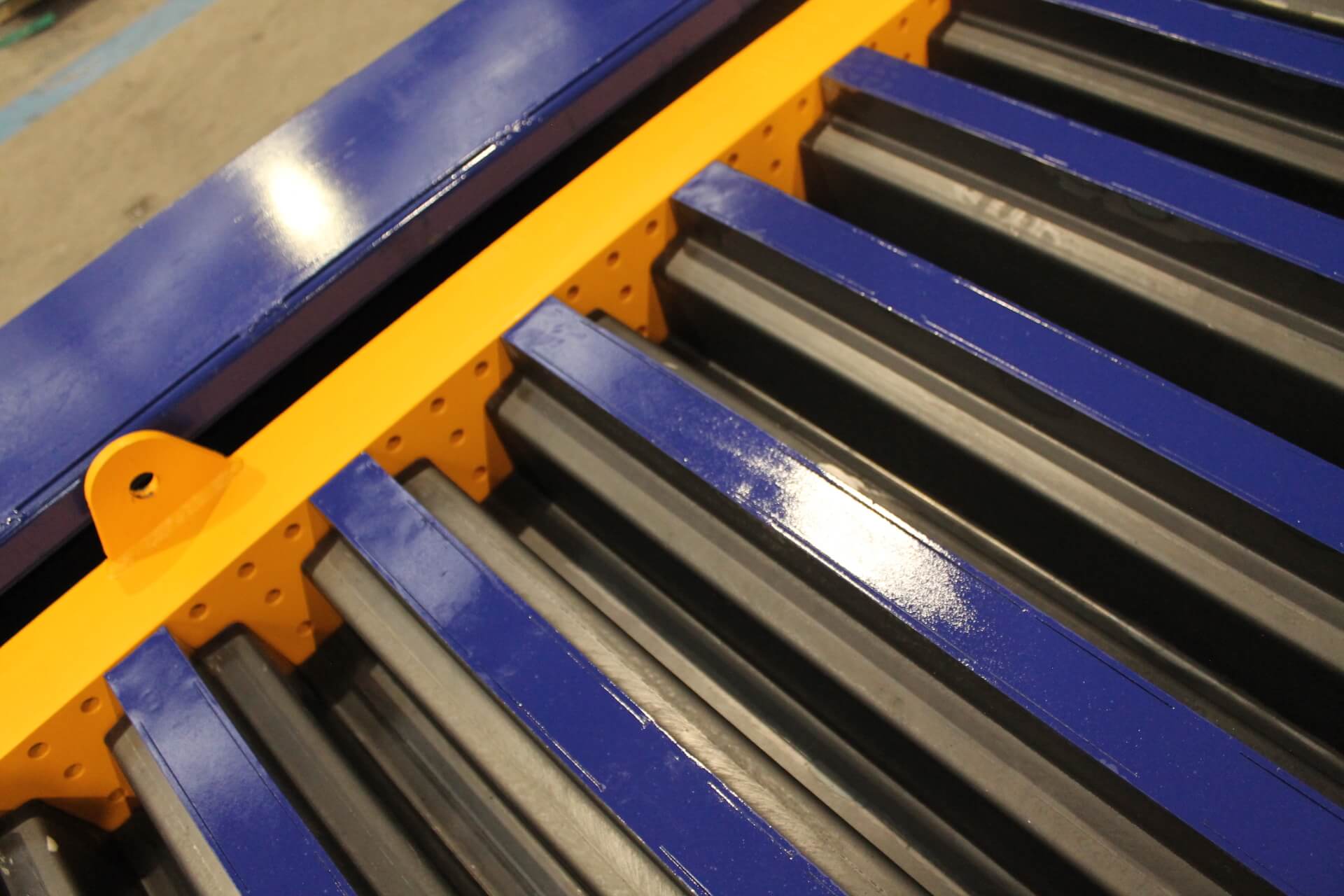

The self-reacting battery table for prestressed joist beams is a system that allows the production of standard sections joist beams and with a high degree of technical quality. MOLDTECH will adapt the equipment to the section of the joists and the production capacity required by the client. Thus, respect local regulations where this production system will be installed.

The self-reacting battery table is designed to produce prestressed beams with inverted casting and a minimal conical slope, which will allow easy demoulding. These tables usually have 8 to 10 parallel working lines, and length usually is of 11.80 m to facilitate the transportation. So that the usual lengths are of 11.80 – 23.60 – 35.40 – 47.20 m, etc. Generally, these tables do not exceed 80 meters in length.

The equipment features the following components:

- Prestressing heads

- The self-reacting battery table

- Cross separators

- Hydraulic tensioning and detensioning units

Advantages of the Moldtech self-reacting system for the production of joist beams:

- High quality of the final product.

- Low investment compared to track production methods.

- Fast production speed.

- Production capacity according to customer requirements with the possibility of future expansion.

- Very few personnel required, high labour efficiency.

- Flexibility to produce lengths of all types without the need to cut concrete.

- Sections of joists according to the customer’s technical specifications.

- Low investment in civil works. The self-supporting table is installed on a simple concrete slab with double steel mesh.

- Easy relocation of the self-supporting table if required.

Moldtech continues to drive high quality manufacturing and production efficiency with its products.

SIMILAR PROJECTS: BATTERY TABLES TO PRODUCE BEAMS IN FRANCE