Moldtech consolidates its presence in Australia with the supply of a big quantity of modular moulds to produce box culverts of wide variety of sizes and ancillary equipment.

The client, a leading supplier of construction materials and precast elements, required flexible moulds for a wide range of sizes that could also allow an efficient production, reducing the need for the crane during operations.

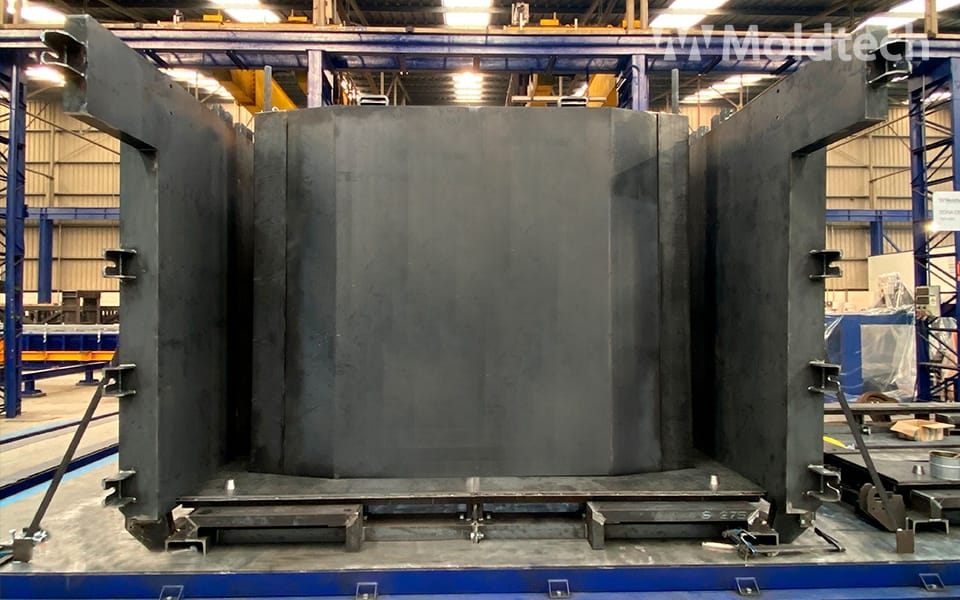

These moulds have been specially designed with collapsible outer sides and a shrinking core mechanically operated by spindles, to allow demoulding the finished culverts without having to remove any of the mould panels, thus reducing the use of overhead cranes.

The 18 moulds delivered allow producing box culverts of many different sections, from 1,2×0,9m to 2,4x3m with 2,4m height/depth. Together with these moulds, the site has also been equipped with 2 hydraulic turners 90º, to turn the culverts from casting position to their final position for transport and installation.

Having in mind the current travel difficulties and restrictions, these moulds have been designed to be easily installed by the local staff with minimal instructions, not requiring on site installation by Moldtech technicians.

At present, production is running at full capacity, producing a good quantity of culverts for the construction of a large number of underpasses for a big railway infrastructure project.

|