Technical innovation for the mass production of double-tee slabs

Germany: a demanding and highly technical market

Germany represents one of Europe’s most demanding and specialised markets for precast concrete construction. Characterised by stringent quality regulations, high environmental standards, and strong demand for technical precision, the German market continuously drives manufacturers to implement advanced and sustainable technological solutions.

Currently, Germany leads the European market in industrialised construction, with an industry valued at approximately USD 13.26 billion in 2024 and projected to grow at a compound annual rate of 4.82% until 2029. This growth reflects an increasing preference for fast, efficient, and environmentally-friendly construction methods.

The German precast construction industry is distinguished by its innovation, sustainability, and continuous pursuit of technical excellence. It is especially rigorous in selecting international suppliers who must not only comply with technical standards but also deliver innovative solutions that ensure the success of complex and ambitious projects.

Tradition and innovation in precast construction

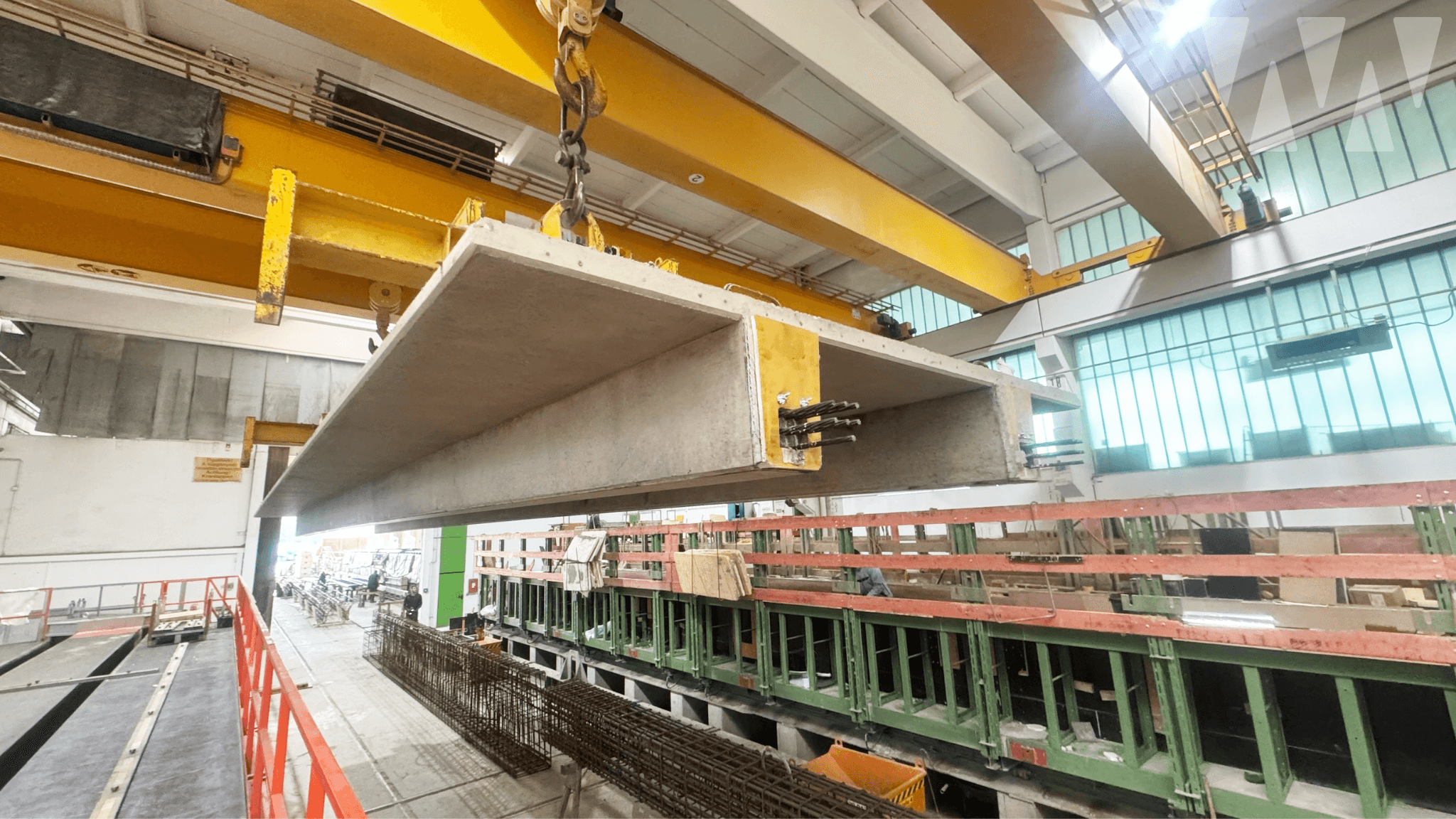

Based in Neumarkt (Germany), this customer is a fifth-generation family-owned business with a strong track record in industrialised construction, particularly renowned for its turnkey projects. With six strategically located plants across Germany, the company manufactures reinforced and prestressed concrete elements with the weight up to 100 tonnes and lengths of up to 50 meters, achieving an annual production capacity of 500,000 tonnes.

Specialising in constructing administrative buildings, logistics centres, production facilities, supermarkets, furniture stores, stadiums, and car parks, this company has established its reputation through a strong commitment to quality, adherence to budgets and deadlines, and trust generated among its clients.

Corporate philosophy is founded upon continuity, technological innovation, and technical perfection, always clearly focused on economic and ecological sustainability. The values guiding the company include openness, trust, cooperation, and corporate social responsibility, alongside a firm commitment to customer satisfaction.

Its production system prominently features low CO₂-content cement, actively contributing to resource conservation and environmental protection. This commitment to sustainability positions the company not only as a technical leader but also as an ethical benchmark within the construction industry.

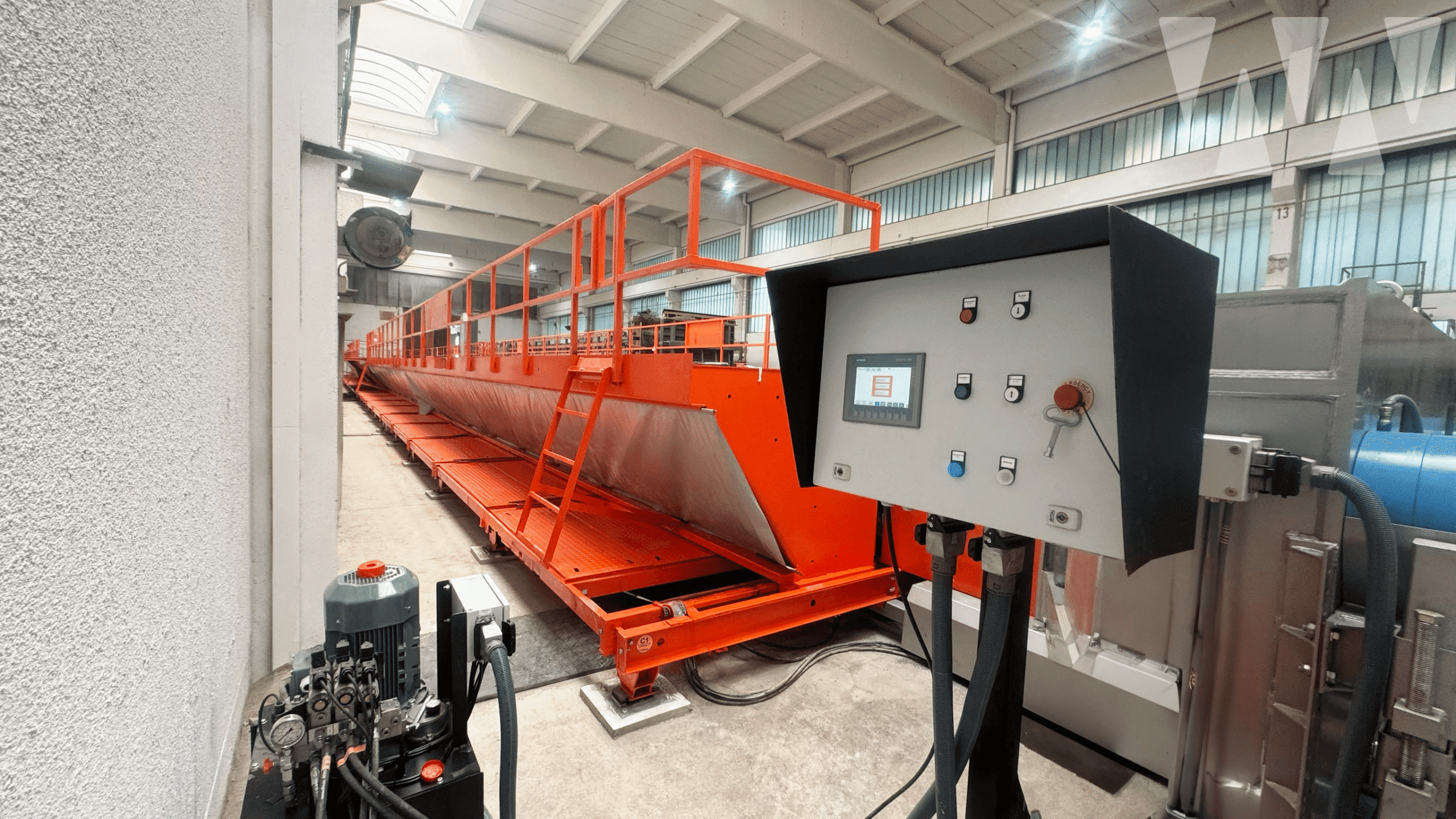

Moldtech supplies high-capacity mould for double-tee slab production

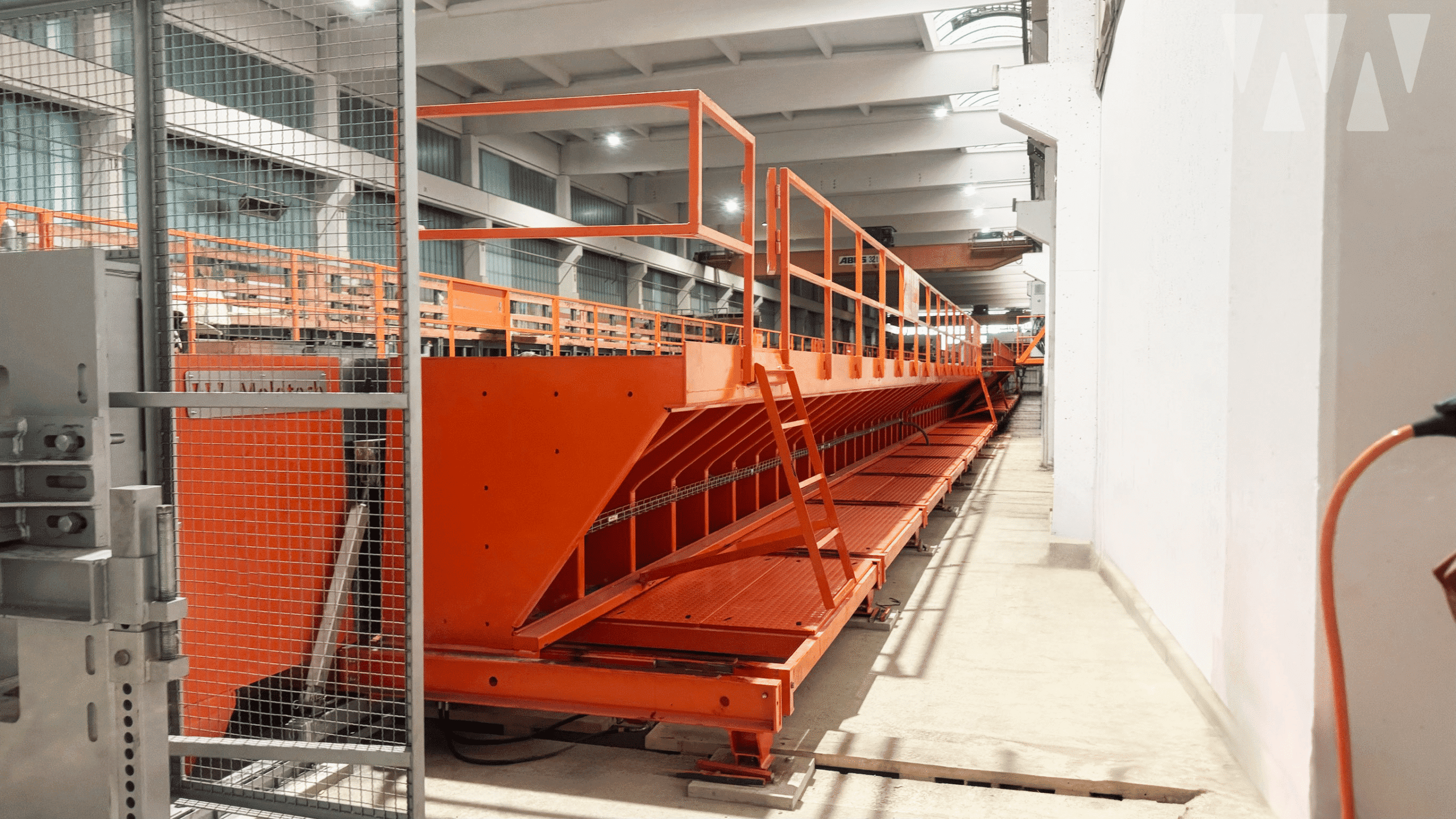

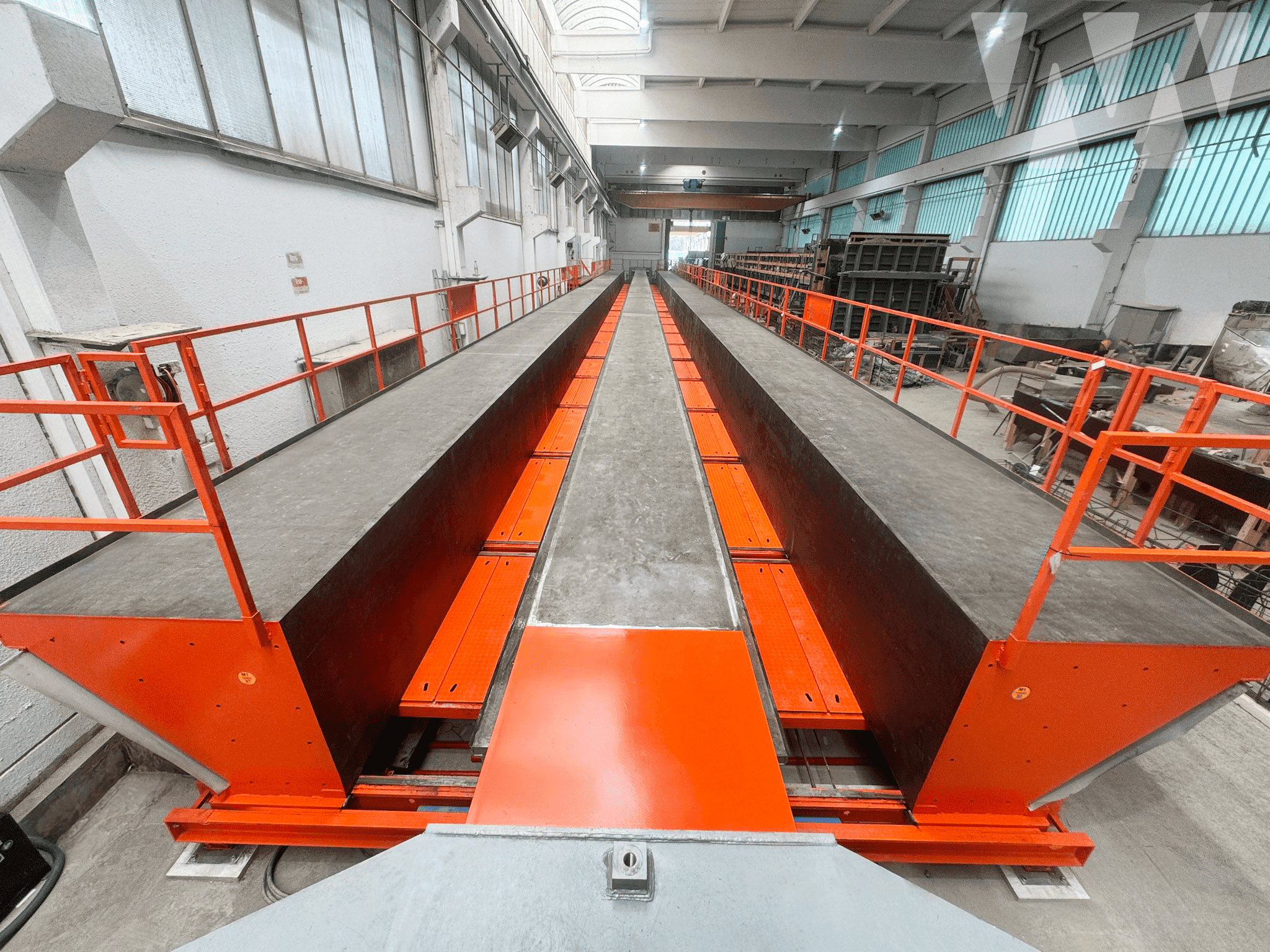

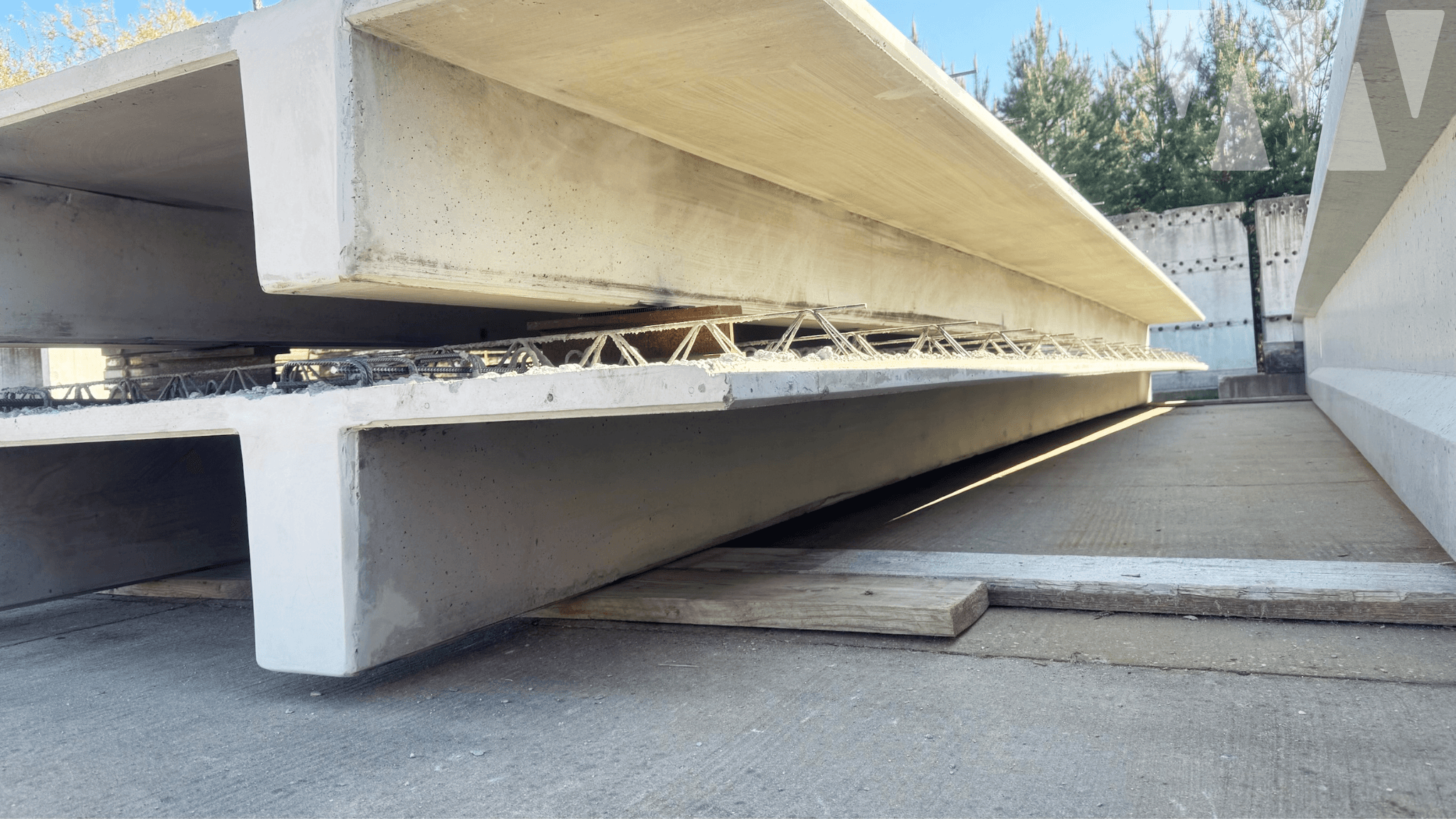

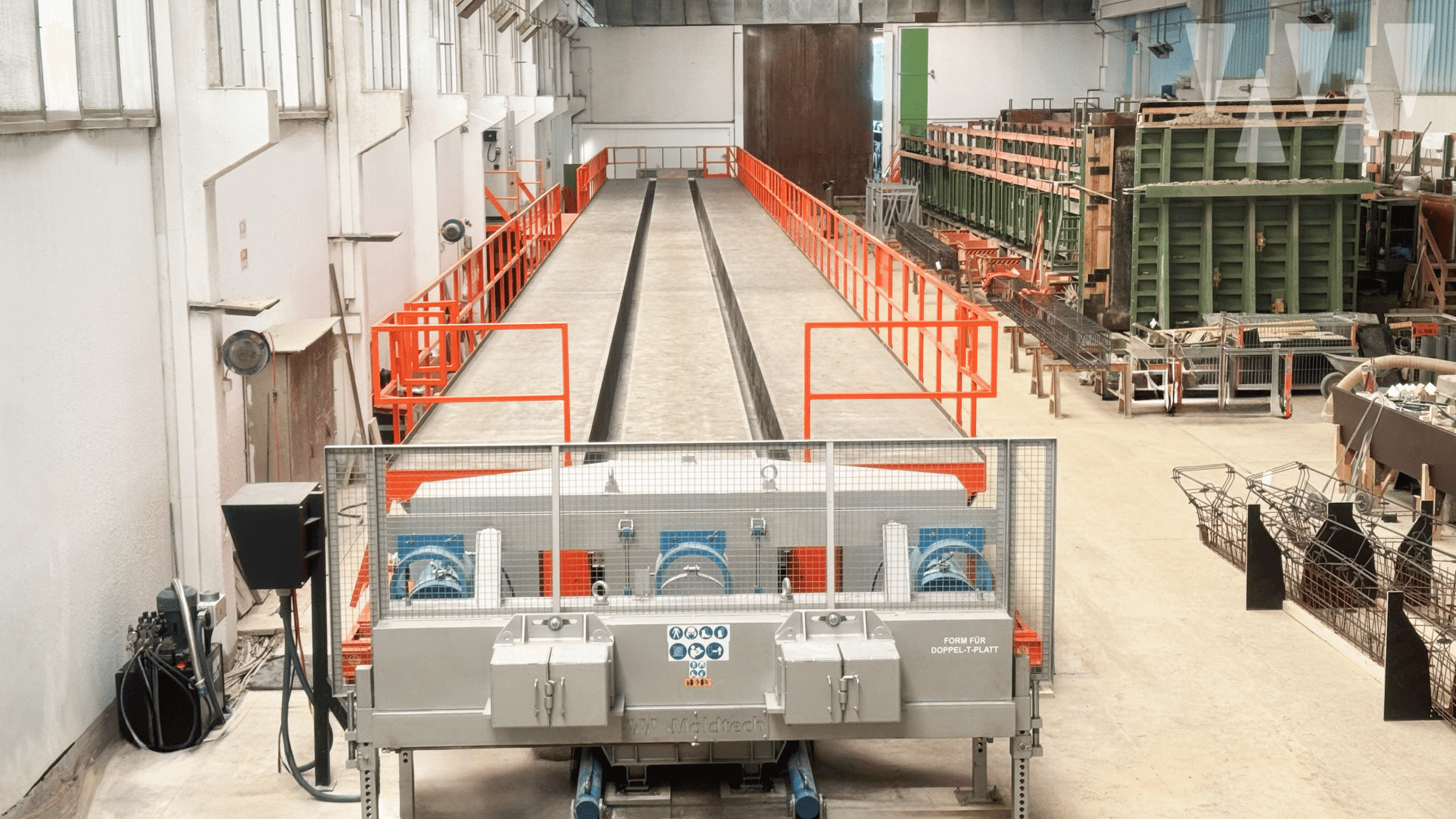

Moldtech has designed, manufactured, and supplied an advanced mould for double-tee slabs (TT slabs), with a prestressing capacity of 600 tonnes and an overall length of 52.5 metres. This mould is specifically engineered for the efficient mass production of prestressed concrete beams with variable cross-sections.

The mould comprises four modular segments, forming a versatile production line capable of adapting to various technical specifications according to project requirements. The beam rib height is hydraulically adjustable, ranging from a minimum of 300 mm to a maximum of 1000 mm. Additionally, it accommodates beam widths varying from 3.5 to 3.8 metres.

Key technological innovations include a hydraulic system for rapid configuration of mould bases, active and passive headers, a digitally controlled electric vibration system, and an advanced heating system that ensures optimum concrete quality regardless of external climatic conditions.

Moreover, it features a synchronised hydraulic relaxation and prestressing unit, equipped with two destressing cylinders of 300 tonnes each, achieving the high total prestressing capacity required. This state-of-the-art configuration guarantees dimensional accuracy, rapid production cycles, and maximum structural strength of the precast elements.

The mould provided by Moldtech will be instrumental in meeting Germany’s growing demand for double-tee slabs, primarily intended for industrial construction projects such as logistics warehouses, car parks, and large infrastructure facilities, ensuring consistent and high-quality production to stock requirements.

Moldtech: commitment to excellence in precast concrete solutions

The collaboration represents a significant achievement for Moldtech in Germany, strengthening its position as one of the leading providers of specialised solutions for the precast concrete industry. The technical capability demonstrated in this project reaffirms Moldtech’s commitment to excellence, technological innovation, and sustainability, aligning perfectly with the requirements of the demanding German market.

With this operation, Moldtech continues to expand its international presence, adding value and reinforcing its reputation as a strategic partner capable of successfully meeting the most complex technical challenges in the global precast concrete market.