Moldtech has recently commissioned new 3D moulds for housing modules (PPVC) in Chile and prefabricated bathrooms (PBU) in New Zealand. These new projects reflect the company´s ability to adapt and apply its technology in different geographical contexts, promoting more efficient, sustainable and high-quality construction practices.

The Chilean company, founded in 1972 as a manufacturer of concrete electric poles, has evolved to become a national leader in the production of all types of prefabricated elements. With five plants in different parts of the country, the company has maintained its position at the forefront of the sector through the constant incorporation of innovative technologies.

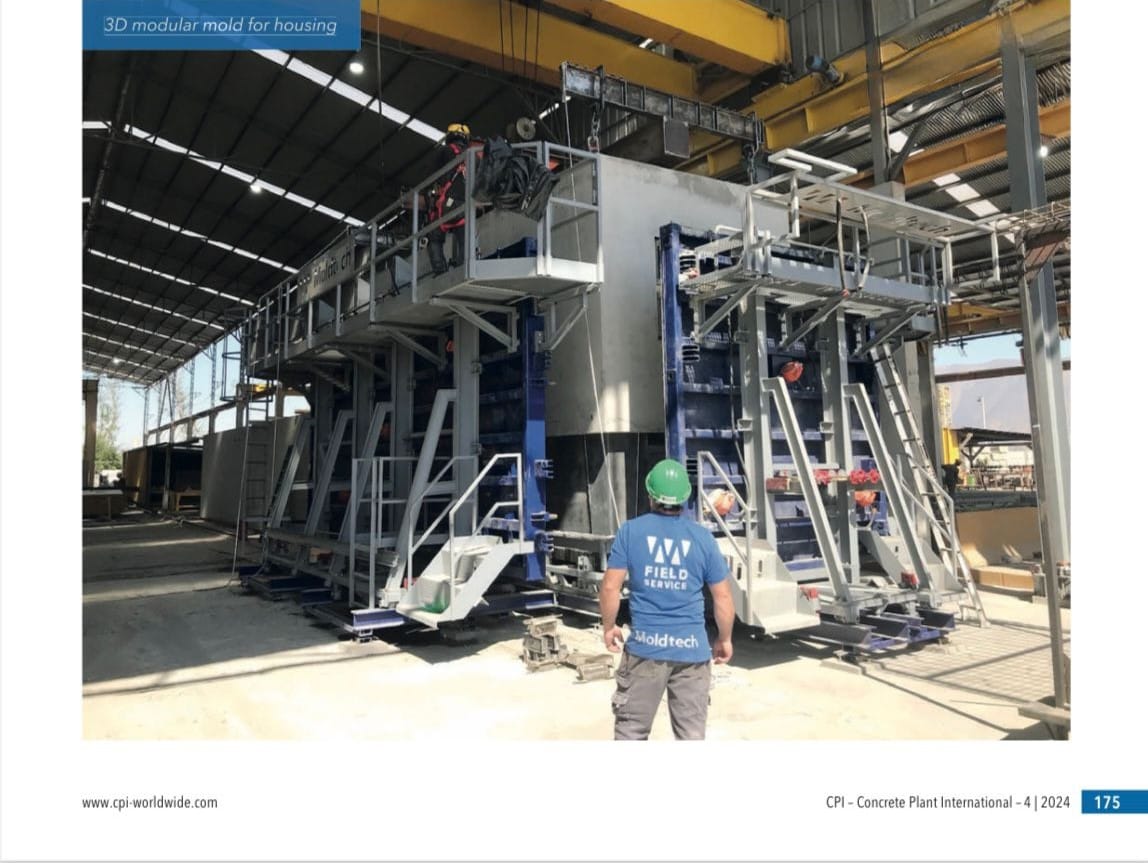

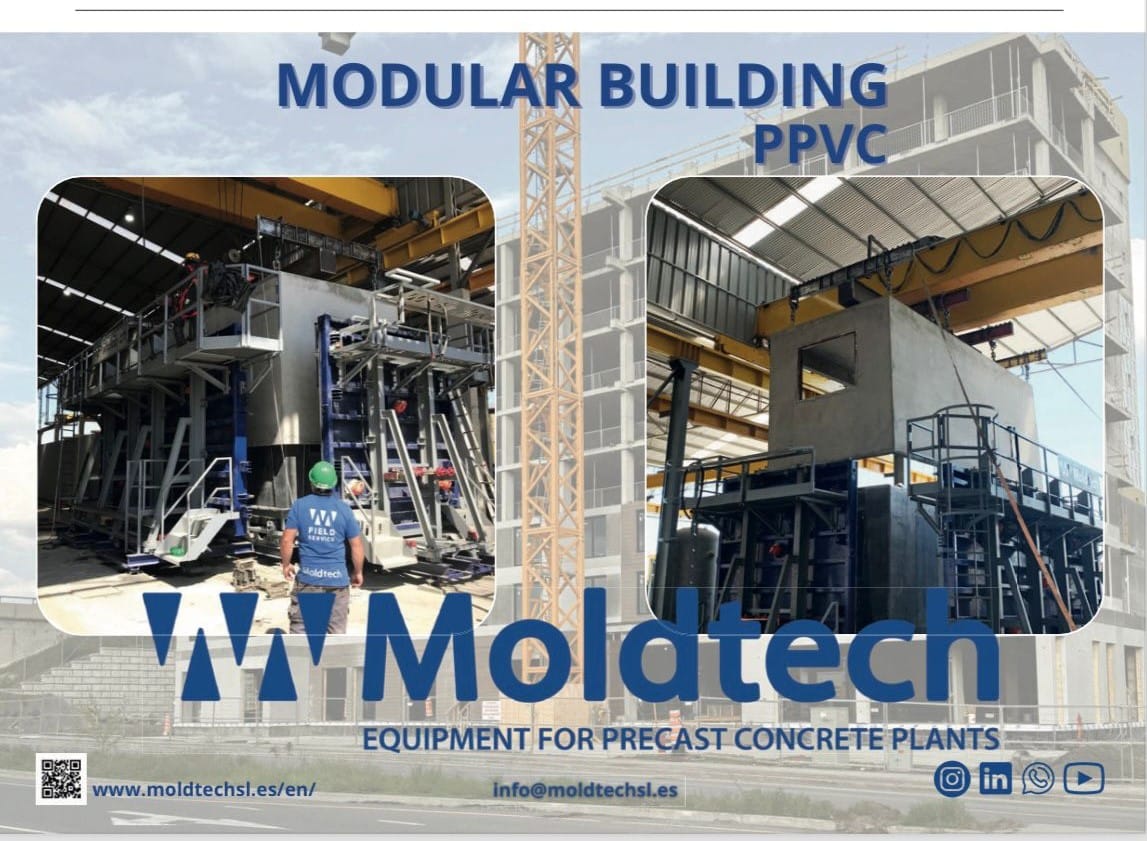

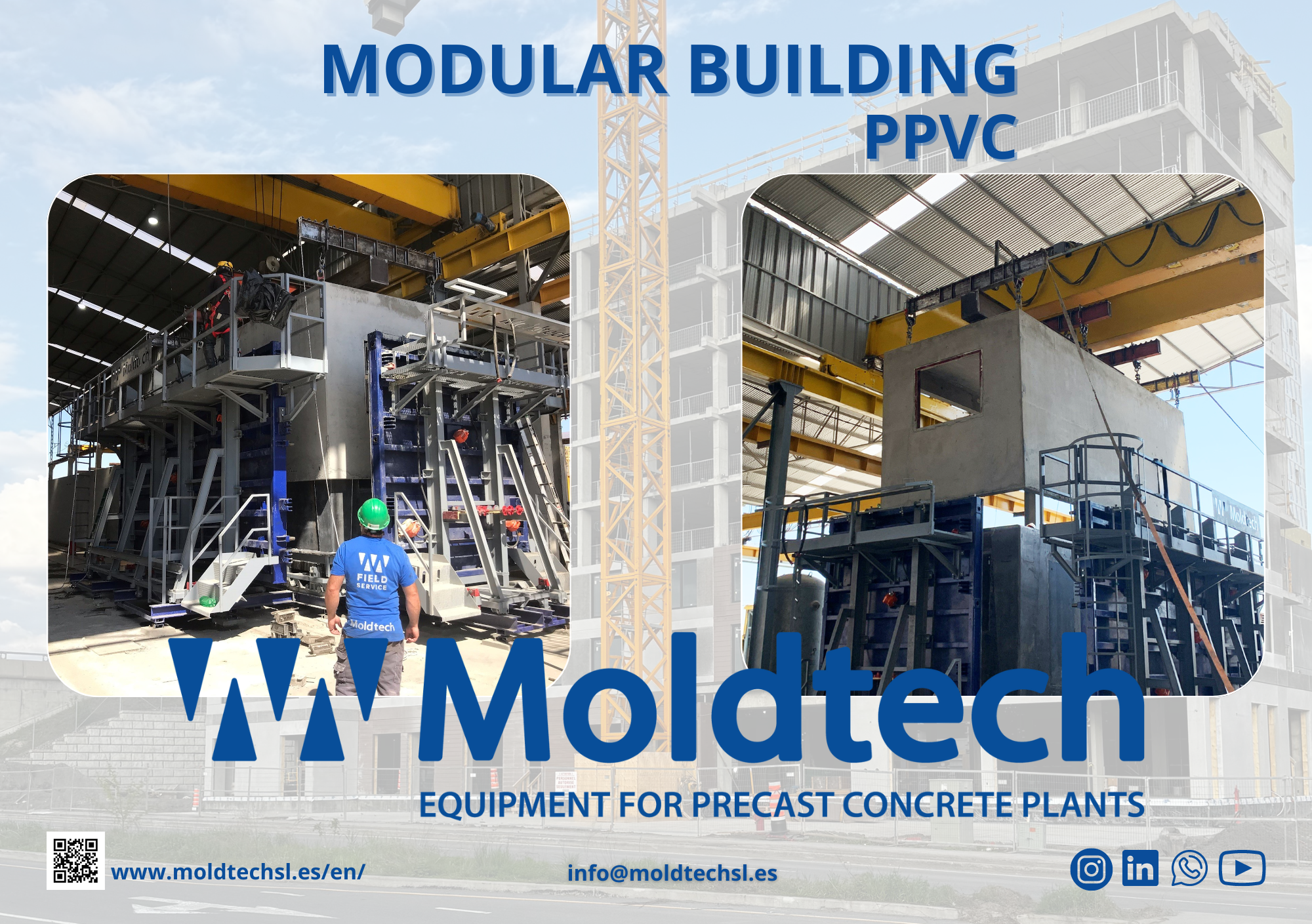

Moldtech has become a strategic partner, supplying a flexible mould for the production of 3D modules for housing projects. This system allows the manufacturing of complete 3D housing modules, with roof and walls casted in a single monolithic piece with the best structural properties.

Precast modular housing represents an efficient and sustainable construction solution. Prefabricated, pre-finished 3D modules (PPVC) go one step further, significantly increasing efficiency and quality control at factory production and considerably reducing on-site installation time, the necessary personnel and their qualifications, achieving unbeatable execution time.

This system can offer great versatility, adapting to both single-family homes and multi-story buildings. Furthermore, these molds allow the production of modules with thermal insulation in the walls that face facades, offering excellent properties, improving energy efficiency and reducing heating and cooling costs.

The flexible mould supplied by Moldtech is designed according to the client’s specifications, allowing the production of 3D modules with variable lengths between 5 and 7 meters, a fixed width of 3 meters and variable heights between 2.50 and 3 meters. It also includes magnetic door and window formworks that can be placed in any position. The exteriors are opened by means of hydraulic cylinders and the hydraulic shrinking core allows demoulding of monolithic 3D modules with straight walls in record time.

Simultaneously, Moldtech has also completed the installation of a 3D mould for prefabricated bathroom units (PBU) with an important New Zealand company.

In this case, the mould is designed to produce 3D monolithic units with floor and walls. The bathrooms are casted in an inverted position and once demolded, the units are rotated 180º to continue with the finishing process in the factory.

In the case of bathrooms, even more efficiency is achieved, with the finishing percentage reaching up to 90%, including waterproofing, installation of tiles, plumbing, electricity, toilets and accessories…

Therefore, these 3D prefabricated bathrooms are even used in combination in construction projects with in-situ concreting or with traditional prefabricated 2D elements.

This mould has also been designed as a flexible system that would allow increasing the lengths of units to be produced in the future, according to the customer’s needs. Likewise, the mould allows the production of 3D bathrooms with variable wall thicknesses and varying heights.

More and more clients trust Moldtech to implement construction technology with 3D modules and improve both manufacturing efficiency and on-site installation processes.

Moldtech has a decade of experience in 3D industrialized construction and high specialization in the design and manufacture of flexible moulds for 3D Modules (PPVC) and prefabricated bathrooms units (PBU). We also design and install adjustable hydraulic turners 180º and automated lines for the complete finishing of modules in the factory, using circulation systems that allow great efficiency and flexibility.

We have extensive experience in this type of plants, with clients in countries such as Singapore, the United States, Malaysia, France, Saudi Arabia, Sri Lanka and Hong Kong.

This double success in Chile and New Zealand highlights Moldtech‘s commitment to modernizing the construction sector. These initiatives not only transform the way homes and bathrooms are built, but also lay the foundation for a new standard in the global construction industry.