STAR TRADING IMPEX S.R.L. is a company that has been working for 25 years in a very competitive panorama. This company has been forging its position in the construction market with its effort and constancy.

At this stage, with such a dynamic evolution, it focuses on civil and industrial constructions. They make tailor-made projects where the execution of urban and natural gas works has an optimum level of quality. Thus Star Trading has come to deserve to be in the position of the best construction companies of the moment in Romania.

The Romanian enterprise focuses on residential buildings, construction of engineering projects for fluids, construction of bridges, roads and construction of civil engineering projects, industrial constructions and autostraps gas supply. All this by the hand of professionals with experience and consolidated reputation in the sector.

In order to be seriously involved in prefabrication systems, Star Trading has acquired a complete prefabrication plant destined to the construction of industrial warehouses, commercial buildings, parkings and civil works.

Study phase work

The joint work in the study and definition phase of the prefabrication project has enabled Moldtech and First Technology as local agents to develop the most suitable production system for the customer.

The experience and technical mastery of Moldtech’ s prefabrication engineering have been the key to this project. Our team of engineers has worked hand in hand with the costumer to define the constructive system and adapt it to the specific needs of Romania.

In an environment where prefabrication is booming, Moldtech’ s experience and technology transfer have enabled the customer to find in “know-how” what it takes to become a pioneering leader in prefabricated concrete elements.

Equipment installed by Moldtech for industrial plant

Moldtech has designed, supplied and installed in this new industrial plant in Romania the following equipments:

- A 100-metre universal track with 1000 TN tensioning heads. Structure formed by a work-table mounted on a frame. The mold is installed on the board and determines the geometry of the work piece to be manufactures. Composed of assembles modules has 100 m long and 1 m wide.

- A 100-metre universal track with 1300TN tensioning heads. It is a similar structure to the previous one, but with other dimensions.

- Side molds for I beam, delta beams, T and L beams. It consists of a set of sides to mount on a universal track bottom, forming a formwork or mold with the desires piece shape. The installation is supplied with pneumatic vibration system.

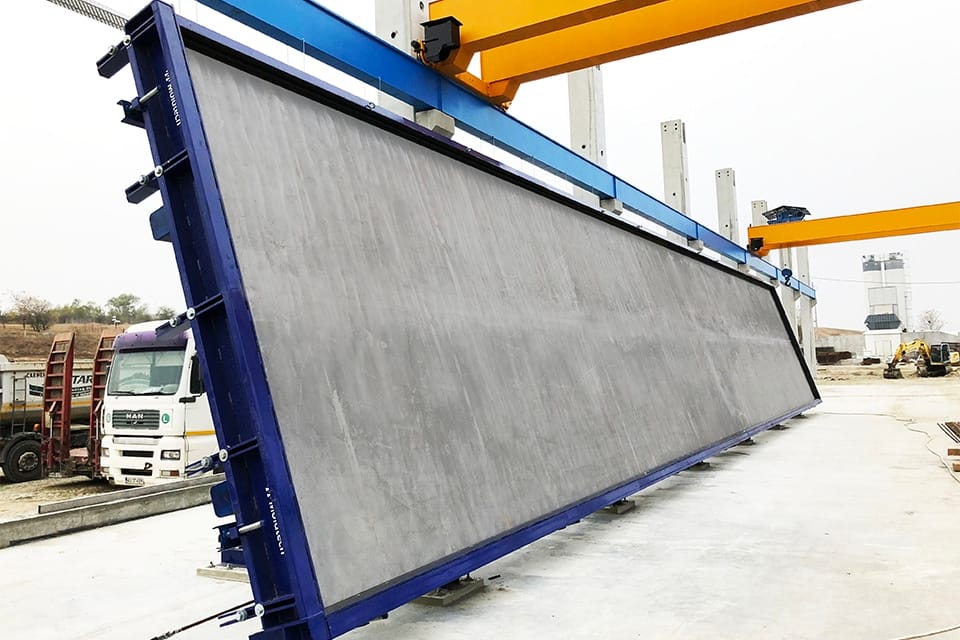

- A 24 x 4,0 meters tilting table. It is composed of 2 modules of 11.8 m long and 4 m wide. The Union of the modules configures a line of 23.6 m long.

Each module is, in turn, composed of a frame with supports fixed to the foundation by means of bolts. The structure and board of the tilting table are mounted on the frame. The module is provided with hydraulic cylinders, to tilt the table, and electric vibrators.

The table has side bands throughout the length of the line. - A 72-meter TT plate mold Hydraulic. It consists of 6 modules of 12 m long and 3.25 m wide. The Union of the modules configures a line of 72 m long. The mold is composed of a central body, with supports fixed to the foundation by means of bolts, and two movable lateral bodies, that are actuated with hydraulic cylinders and determine the dimensions of the final piece. For cable tensioning, an active moving head and a fixed passive head are available. The installation is supplied with pneumatic vibration system. The mold is accompanied by a hydraulic switchboard and electrical panel where all the manoeuvres are carried out.

- A 16-metre beam mold

- A double mould of columns of 36 meters and maximum pillarof 1.00 x 1.00. This machine consists of a bottom and a set of double height adjustable sides. At the same time, it has different cylinders that make and help to the demolding of the piece. In addition, interior core pulls to provide the piece with the desired configurations by the customer.

- A stair mold of an adjustable universal-type stretch. The stair molding equipment consists of a module of 7 m long, 2 m wide and 2 m high. It is made up of a frame fixed to the foundation by means of threaded rods. On the frame there are two sides configurable in height.

At the same time the frame is to be mounted on a set of plates mounted on top of each other, the main function will be providing the different configurations in the part. The installation is supplied with pneumatic vibration system. - A transport “Giraffe” and concrete pouring. This machine has been preconceived to self-propel the transport and distribution of concrete. The machine consists of a hopper and an endless channel. These elements are mounted on a chassis with wheels and a swivel platform with tilting system. It also has a control and driving position.

The machine is designed to be used in the industry and with a maximum load of 7200kg.

|