Moldtech supplies a TILTING TABLE to a prominent customer in the construction sector in Spain.

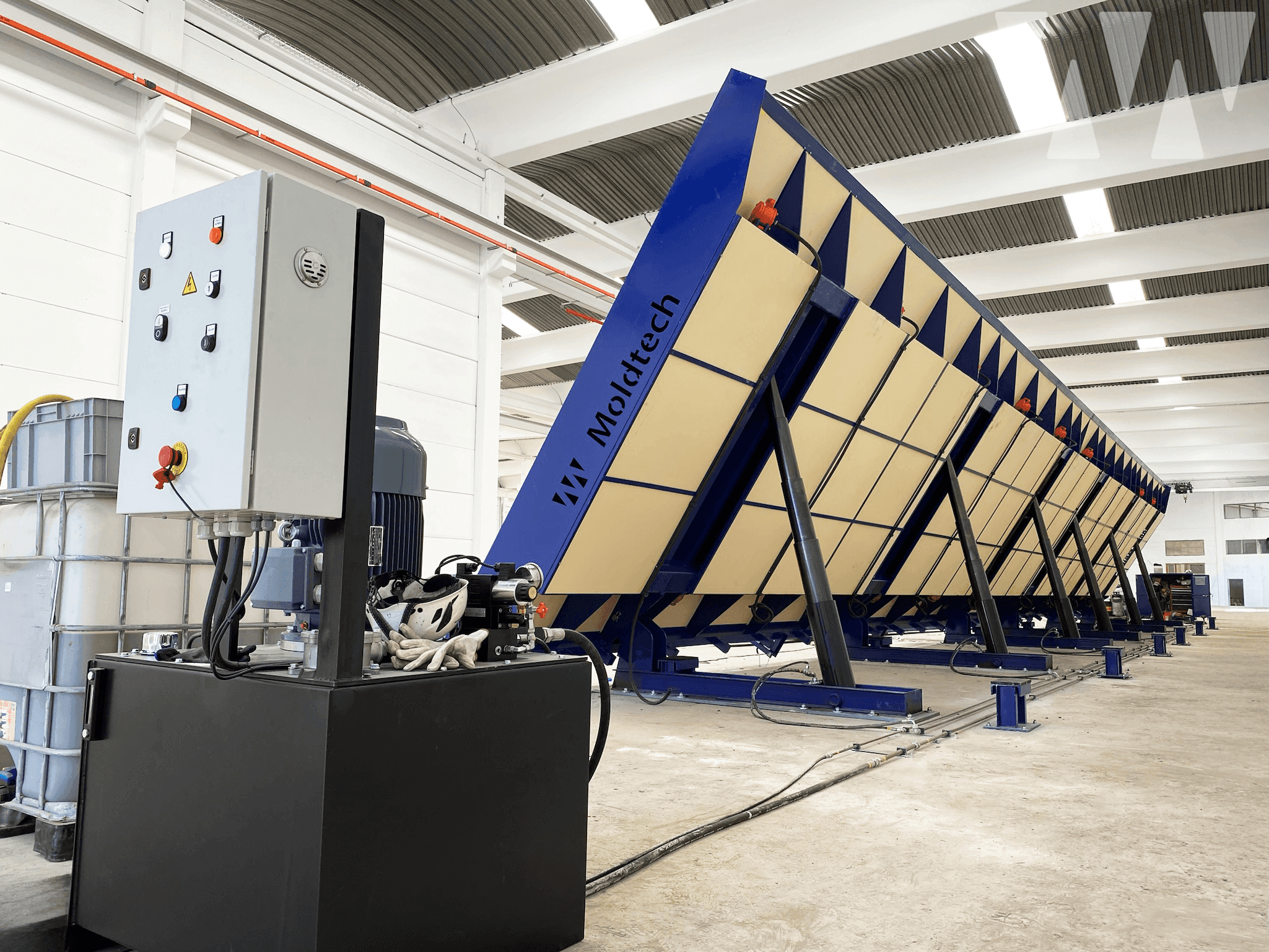

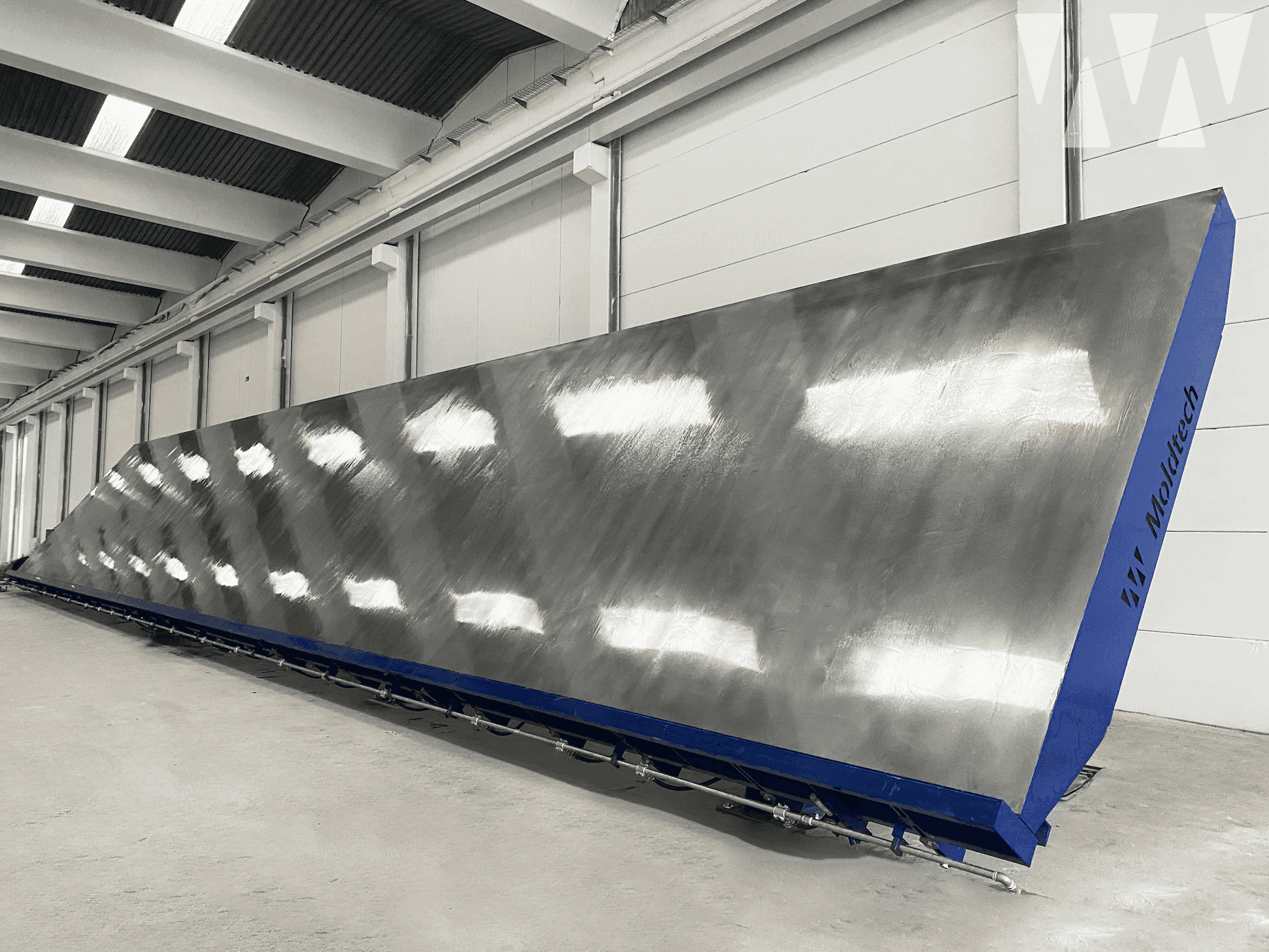

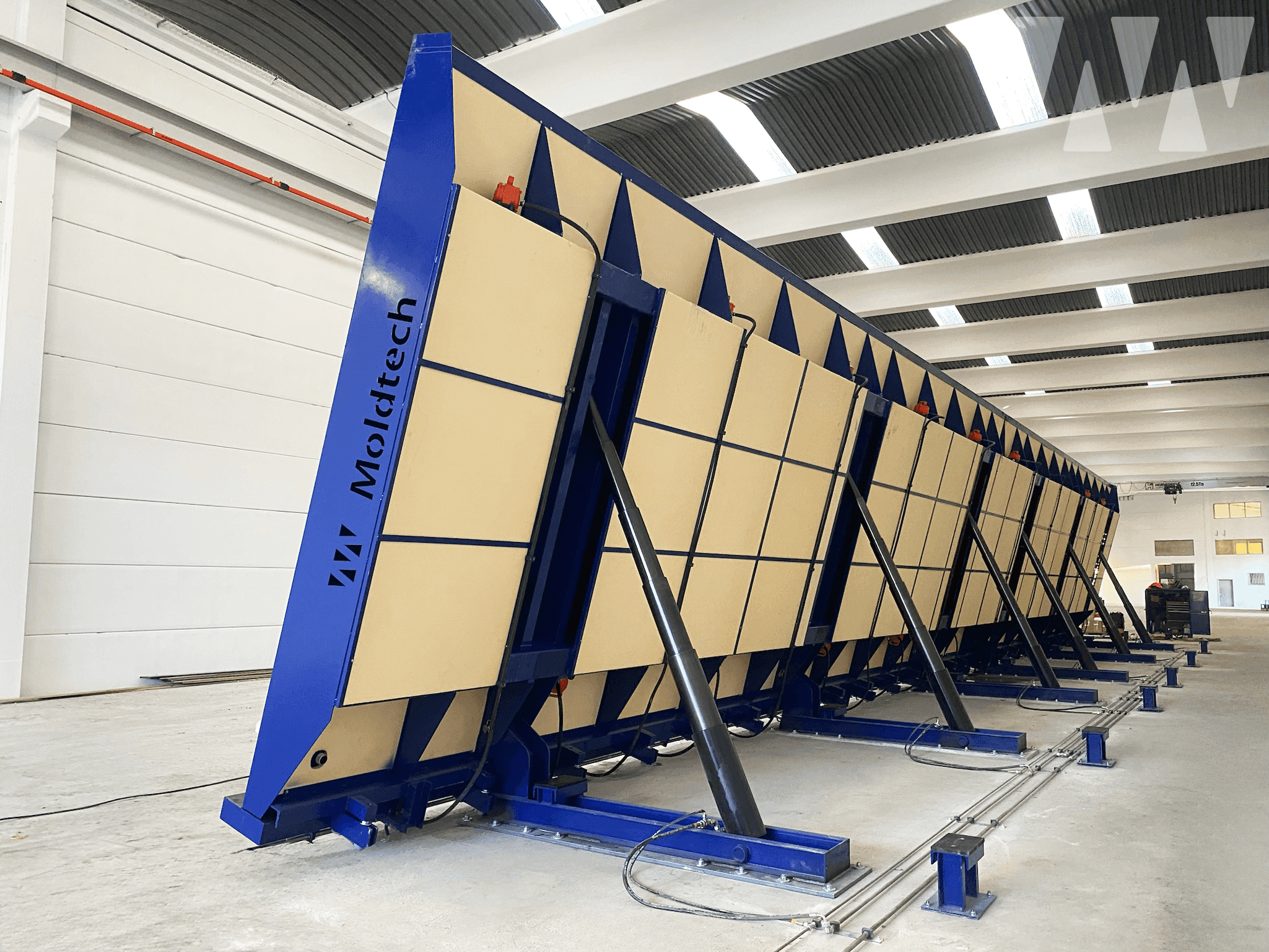

The TILTING TABLE is made up of two 13 meters long modules, which, when assembled together, make up a production line of 26m long and 4.2m wide. The modules are made up of supports fixed to the slabs, which, together with a frame and tilting table top, allow a maximum inclination of 74º.

The table has a lower longitudinal shutter that can be mechanically adjusted in height, which makes it possible to manufacture elements with a thickness of between 160 and 300 mm. The table is tilted by means of hydraulic cylinders, driven by a hydraulic power unit and a main control cabinet.

It is also supplied with made-to-measure insulating panels to be attached to the underside of the table.

The moulds designed by Moldtech are designed to ensure that the parts produced are accurate and uniform. In addition, the technology used in the manufacturing process not only increases accuracy, but also allows for more cost-effective production.