Moldtech supplies an 800T prestressing system to a client in Romania.

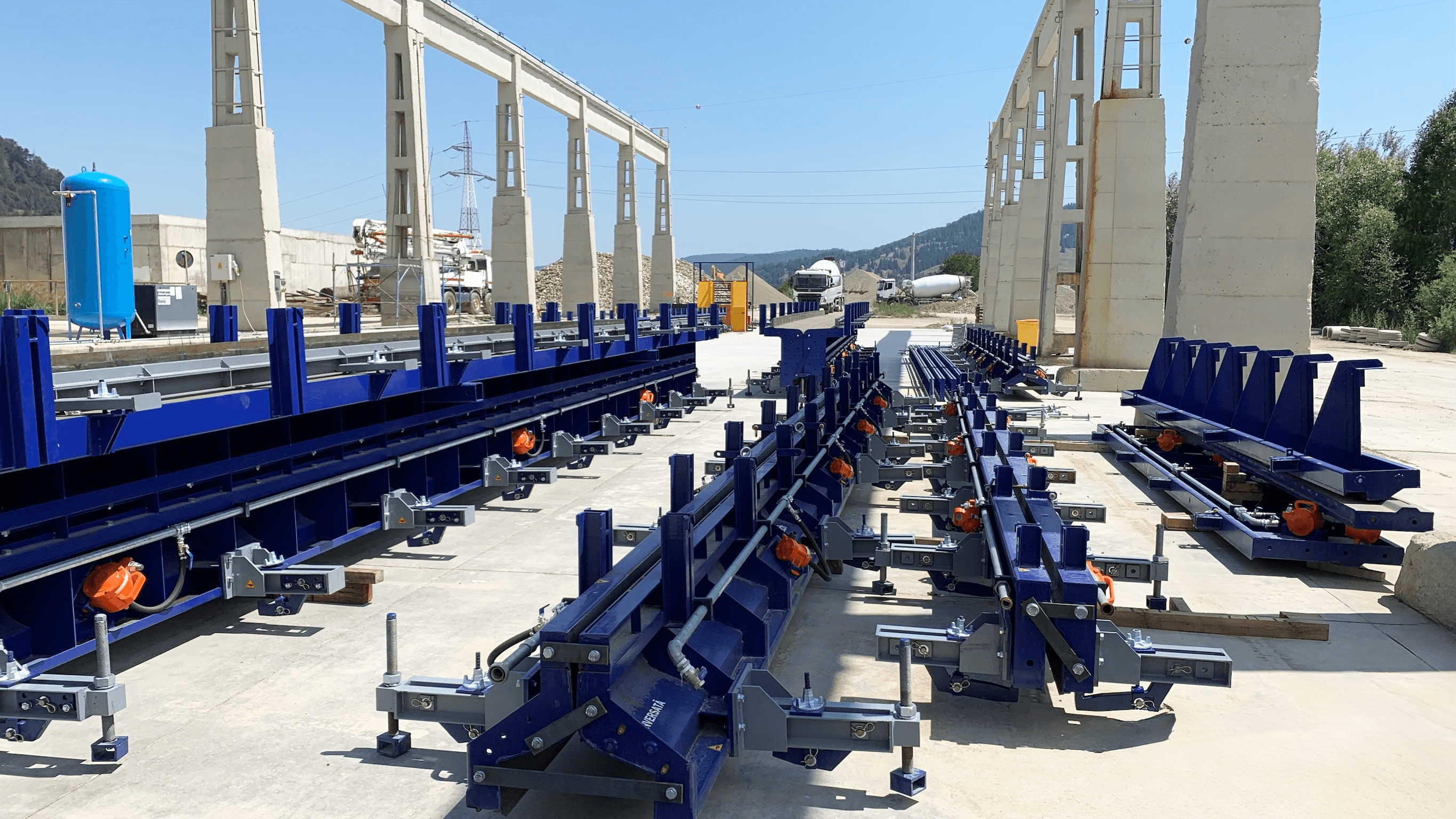

The 800T SELF-REACTING PRESTRESSING BENCH is made up of an active stressing head and a passive stressing head, located at the ends of a universal casting bed, which together with the set of side moulds shape the elements to be manufactured.

The side moulds supplied are the following:

- Side moulds for Dalla beam L=19 m

- Side moulds for the Marginal beam L=6 m

- Side moulds for Inverted T beam L=25 m

- Side moulds for H beam L=26 m h=0.72/0.80 m

- Side moulds for I beam L=25 m h=0.95-1.05 m

With this equipment, it is possible to achieve precise, high-quality manufacturing, optimizing the production process and guaranteeing a final product that meets the most demanding standards in the sector.