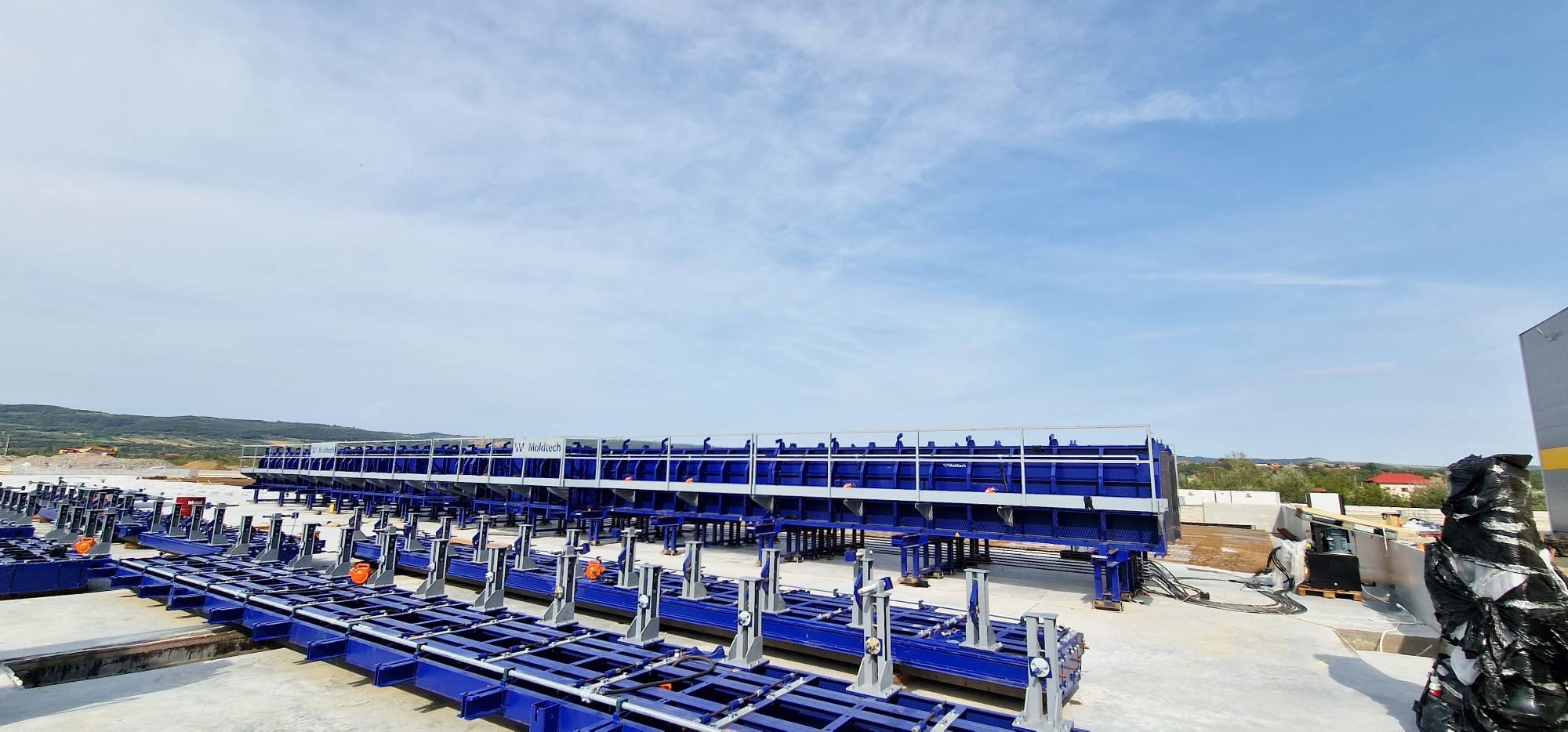

Moldtech completes the project in Romania by supplying a 1000 T prestressing system and a double hydraulic mould for column.

The 1000 T PRESTRESSING BENCH is designed for the manufacture of prestressed concrete beams on a universal casting bed of 85 m in length and maximum width of 1.2 m.

The scope of supply:

-1000 T stressing heads

-85 m x 1.2 m universal casting bed

–I beam side moulds H=0.6-1.4 m, L=26 m

–DELTA beam side moulds L=38 m

-LTR beam side moulds L=28 m

-Strands decoilers

DOUBLE HYDRAULIC MOULD FOR COLUMNS L=36 m, for simultaneous production of two columns with variable section from 500X500 mm to 1200×1200 mm. The machine is made up of two 36 m sides, a central panel, two configurable bottom supports and removable stoppers, which when assembled together give shape to the piece to be manufactured.

This project reaffirms Moldtech‘s position as a leader in solutions for concrete structures, offering advanced and versatile equipment that optimizes production in Romania and stands out for its efficiency and adaptability.