Designed for high productivity of precast concrete panels in a small space.

Do you want more information?

Contact an expert from our team now

- +34 955 444 190

- info@moldtechsl.es

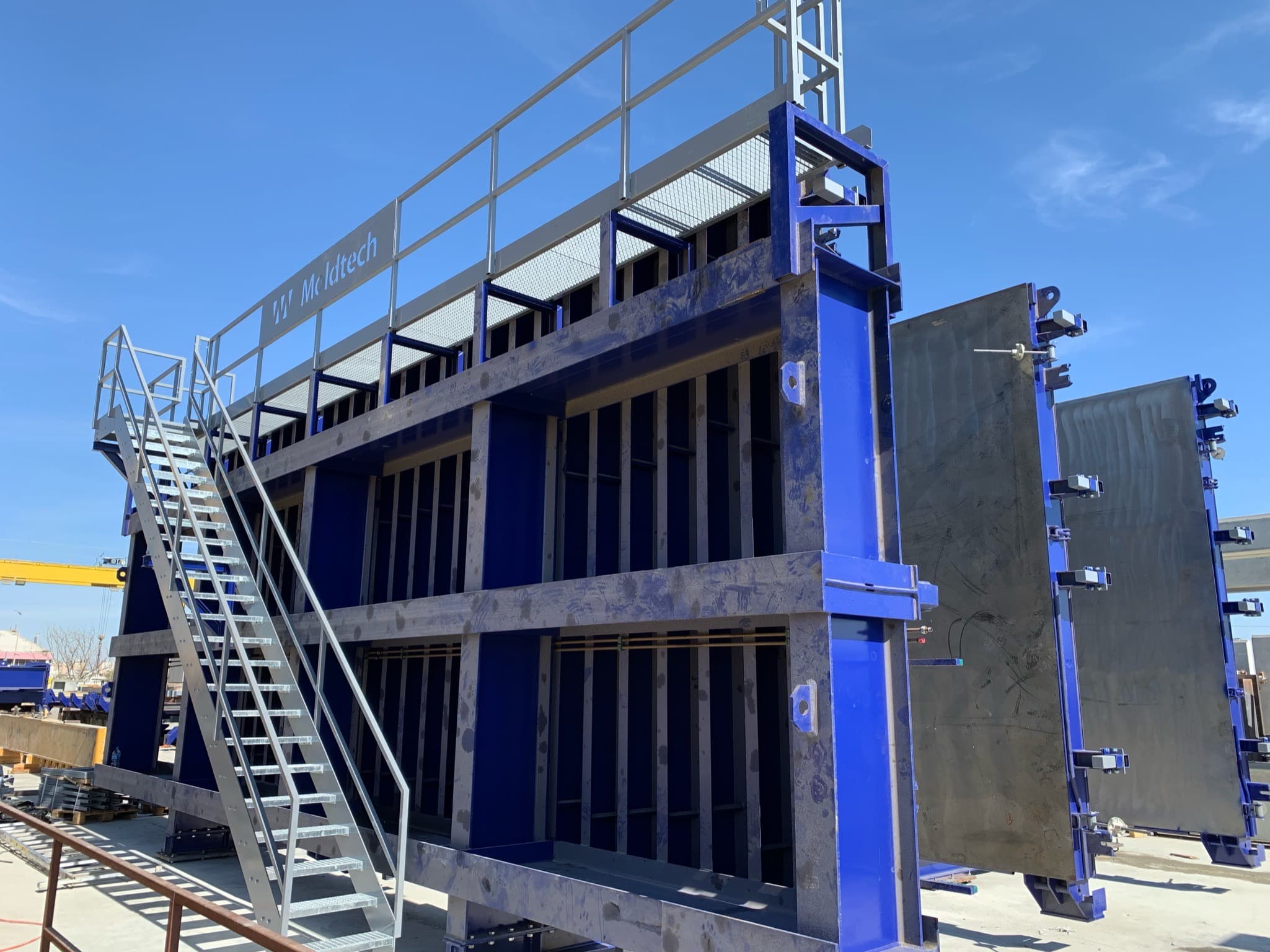

Designed for high productivity of precast concrete panels in a small space.

The vertical battery mould allows manufacturing concrete panels with the desired dimensions and with a specific finish on both sides of the precast concrete panels.

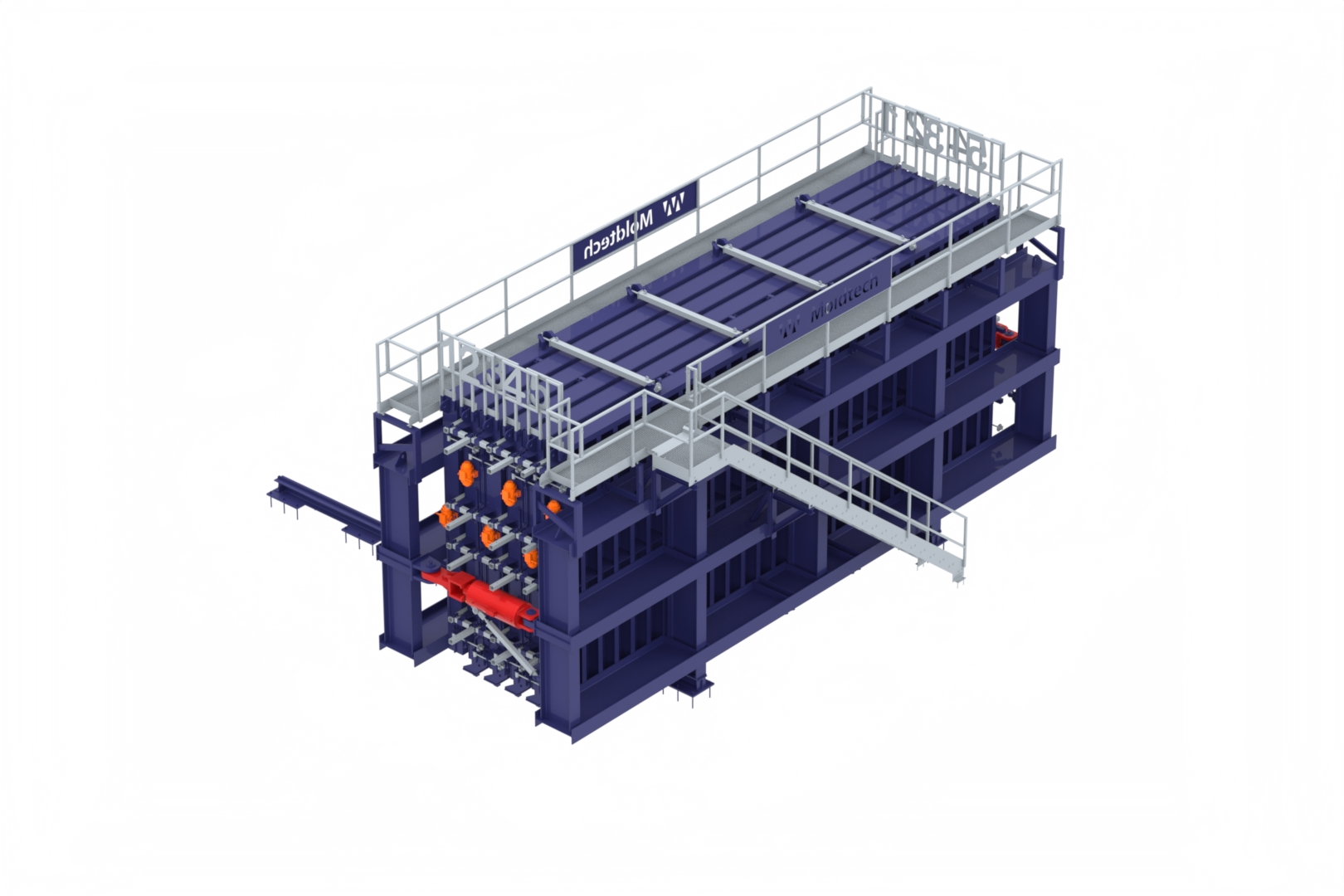

The vertical battery mould is a machine specially designed for high productivity of precast concrete panels in a small space. An additional benefit of this production system is that the precast panels are already extracted for its stockpiling and transportation in the final position which they will be installed on site.

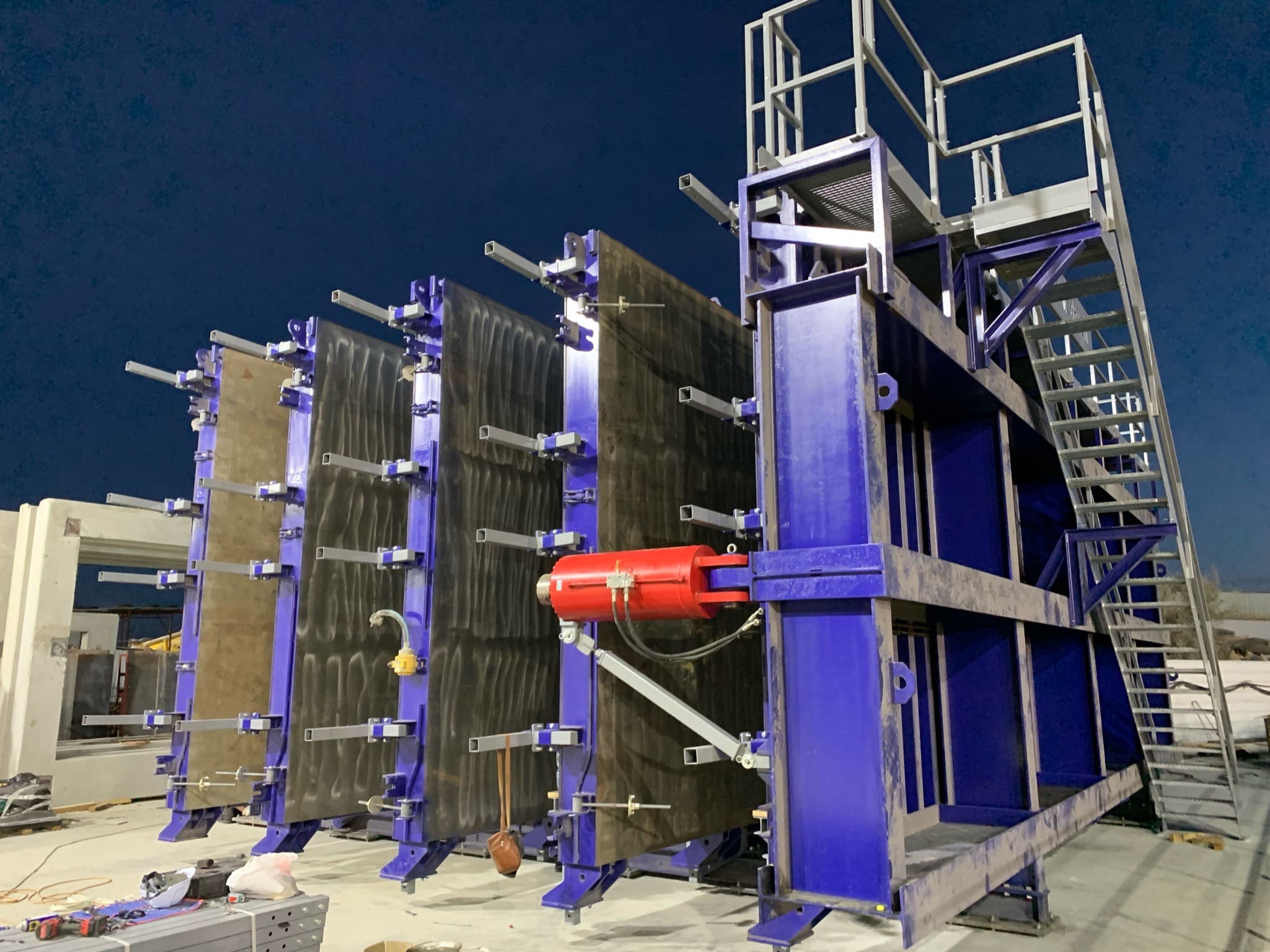

Constructively, it has a main structure or frame with rails on one or both sides, on which roll some steel bulkheads that function as separators between the concrete panels. Between bulkhead and bulkhead, formworks with sealing gasket are positioned as well as constructive and finishing elements required by the precast concrete panel.

The production process begins with the placement of formwork for both the perimeter of the panel and the windows and doors openings. Then, elements such as pipes, through-wall grille or electrical wiring are arranged on the bulkhead. Finally, the release agent is applied and all the process is repeated in the next bulkhead.

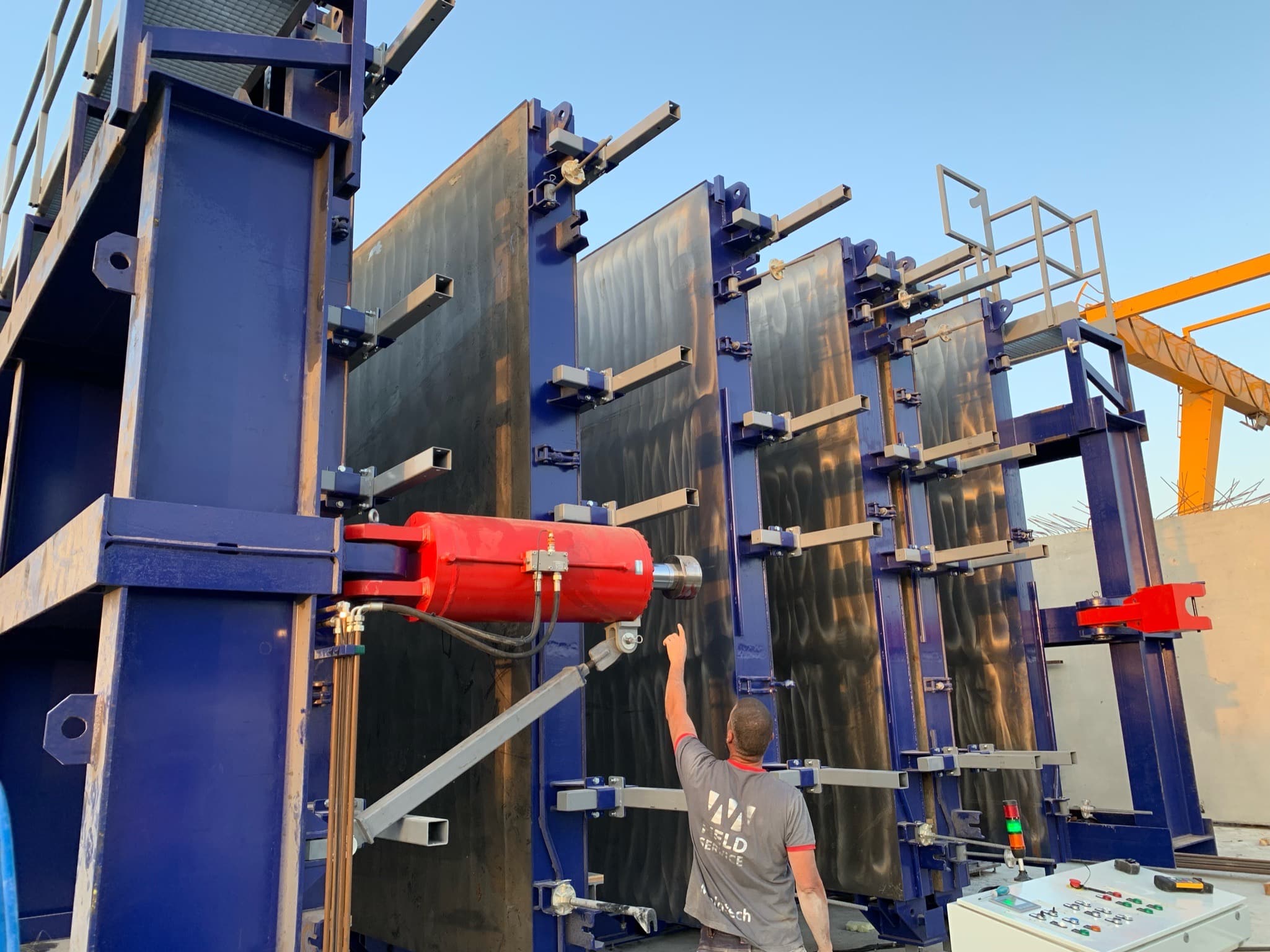

Then, the mold is closed, usually with the support of a hydraulic system, and all the locking mechanisms are activated. At the top will rest the openings for filling the casting slots, where the panels will be produced.

A complementary function which is usually implemented in vertical battery mould is the electrical vibration system, allowing the compaction of the concrete and its formulation with lower water content, so that improve the productivity. At the same time, this function helps to eliminate air bubbles and optimizes the finishing on both sides of the precast panel.

Further, the vertical battery bulkheads may include a piping system for the circulation of hot water or steam, which allows providing heat to the curing process of the concrete and reducing the time required for hardening and removal of the concrete panel.

As for the surface finish, bulkheads are supplied with a polishing treatment that gives a mirror effect to the precast concrete panels.