Prestressed concrete plays a crucial role in modern construction, revolutionizing the way structures are designed and built. Incorporating this advanced technique allows engineers and builders to increase the durability and flexibility of their projects. Understanding prestressed concrete is vital for industry professionals, as it opens the door to innovative solutions and greater efficiency. In this article, we will delve into what prestressed concrete is, its applications, and the advantages it offers in various construction sectors.

What is prestressed concrete?

Prestressed concrete is a form of concrete in which internal stresses are intentionally introduced to counteract the tensile stresses that will occur during service. Unlike traditional concrete, which must support loads as-is, prestressed concrete is pre-compressed, allowing it to support greater loads and span greater distances with less material.

In our experience, prestressed concrete offers significant advantages in reducing material usage while improving structural stability. This innovative method is characterized by its high tensile strength and design flexibility, making it suitable for a wide range of applications, from bridges to high-rise buildings.

What Are the Typical Applications of Prestressed Concrete?

In bridge construction, prestressed concrete significantly enhances design and longevity. By using this technique, we can create slender, lightweight bridges that can span vast distances without compromising on strength or stability. For instance, in a recent project, we implemented a prestressing system that allowed for longer spans, reducing the need for numerous intermediate supports and thereby minimizing maintenance requirements over time.

Prestressed concrete is invaluable in the construction of high-rise and commercial buildings. It allows us to create large, open spaces without the need for excessive columns, leading to more flexible layouts. This efficiency leads to shortened construction times and reduced waste. When working on residential projects, we found that prestressed concrete allows for quicker build times and less waste.

Moreover, using precast panels made from prestressed concrete enables comprehensive design options while maintaining structural integrity.

Benefits of using prestressed concrete

– Weight Reduction: The efficient use of materials minimizes the overall weight of structures, which can lead to savings in foundation costs.

– Increased Durability: Prestressed concrete is less susceptible to cracking and deformation, ensuring longevity and less maintenance.

– Cost-Effectiveness: While initial costs may be higher, the long-term savings from reduced material usage and lower maintenance make it an economically sound choice.

What we’d do differently today is emphasize more on the long-term benefits of prestressed solutions to clients upfront.

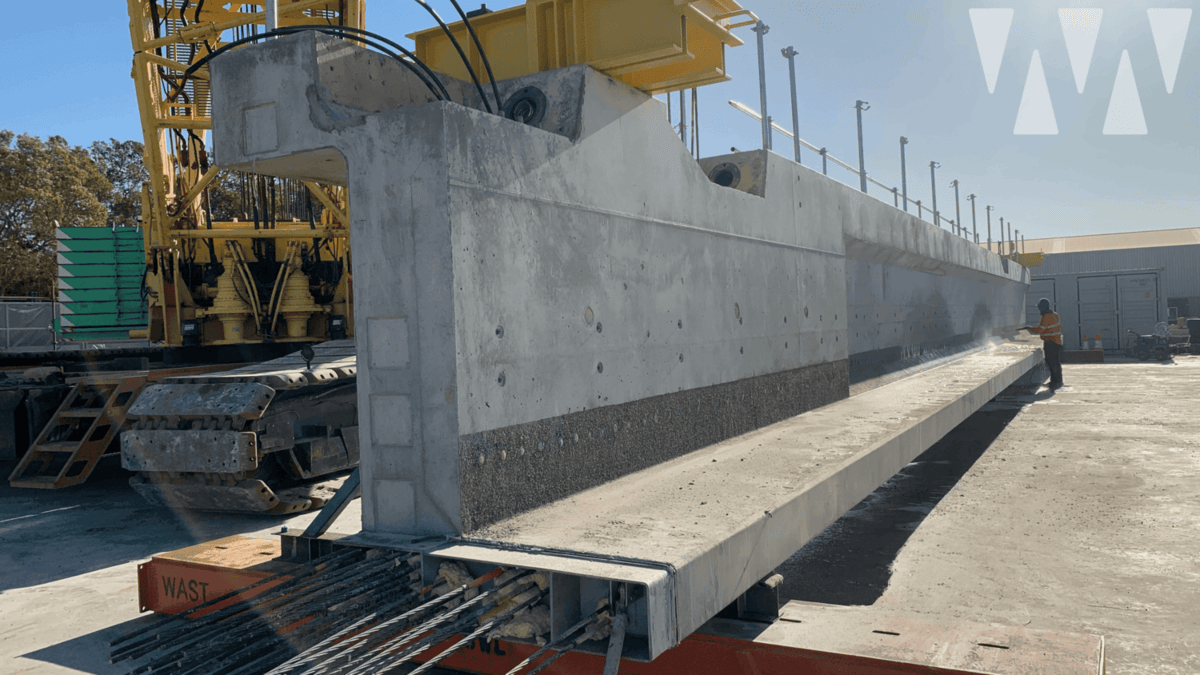

The demand for prestressed concrete is increasing globally, driven by innovative prestressing technologies and methods. Companies like Moldtech are at the forefront of these advancements, offering cutting-edge solutions tailored to diverse construction needs. For instance, our production of specialized molds for pretensioning systems, including self-reacting prestressing systems, has enabled us to serve various international markets effectively.

Conclusion

Prestressed concrete is a game-changer in the construction industry, offering increased performance and flexibility in a variety of applications. If you are considering a project that could benefit from advanced concrete solutions, Moldtech can help you make informed decisions tailored to your needs.

For more information, check out our most relevant projects, such as our Slab Tensioning System in the United States, which exemplifies the advantages and applications of prestressed concrete.