In today’s construction landscape, understanding what is post tension slab is key for engineers, builders, and developers aiming to optimize structural performance and cost-efficiency. A post-tension slab is a concrete slab that incorporates high-strength steel tendons. These tendons are tensioned after the concrete has cured and achieved sufficient strength, creating a controlled compression that dramatically enhances the slab’s capabilities. This process allows it to withstand greater loads, reduce cracking, and span longer distances with less material.

At Moldtech, we see the post tension slab as a key innovation that aligns with the growing demand for sustainable and versatile building systems, especially in precast construction. For those unfamiliar, knowing what is post tension slab helps understand why this technique is revolutionizing modern construction methods.

How Post Tensioning Works

The process begins with placing steel tendons inside ducts before the concrete is poured. Once the concrete reaches a specified strength, hydraulic jacks are used to tension these tendons. This action induces a calculated compressive force within the concrete slab. The tendons are then securely anchored at the slab’s ends. This pre-compression effectively counteracts the tensile stresses that would typically occur under loads, making the slab far more efficient and robust than traditional reinforced concrete.

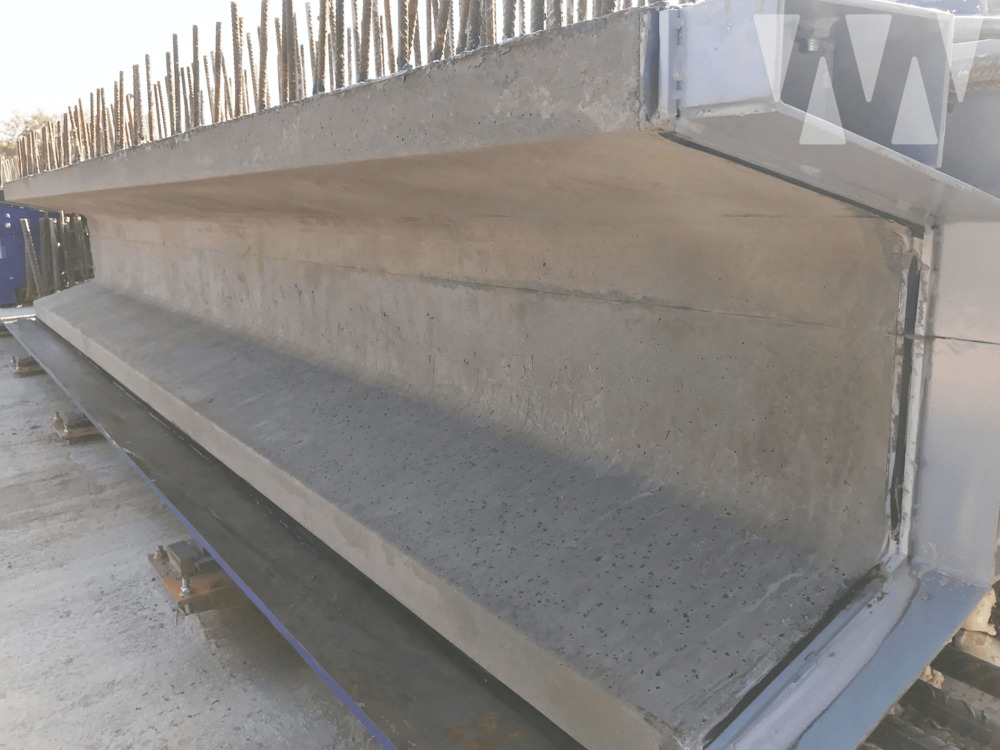

We have successfully implemented post-tensioning in several projects. We’ve seen significant improvements in structural efficiency and cost-effectiveness in our designs, allowing our clients to achieve their project goals with confidence. Additionally, we have produced Post-Tensioned AASHTO Beams for a bridge project in Africa, showcasing our ability to adapt our molds and technology to meet specific project needs.

The Value of Post Tension Slab

Post-tensioned slabs are commonly applied in parking structures, bridges, commercial buildings, and high-rise residential projects. Their primary goal is to create thinner, stronger slabs that minimize material consumption while improving overall structural performance.

Key Benefits Include:

- Material Efficiency: They require less concrete and steel than traditional slabs, leading to cost savings, a lower environmental impact, and reduced dead load on the structure.

- Improved Structural Integrity: The tensioning process enhances the slab’s resistance to bending, cracking, and deflection, resulting in more durable structures with less maintenance.

- Design Flexibility: They allow for designing large, open spaces without intermediate columns, giving architects greater freedom in layout and aesthetics.

Moldtech’s Expertise in Precast and On-Site Applications

At Moldtech, we’ve integrated post tension slab systems into various projects, utilizing our specialized precast molds and custom formwork. Our experience includes manufacturing molds for modular building components and large-scale civil works, where the inherent strength and efficiency of post-tensioned elements are crucial. Our ability to provide the necessary tools and expertise helps bring complex post-tensioned designs to life.

Best Practices for Successful Implementation

Based on our extensive experience, we advocate for several key strategies to ensure the success of post-tension slab projects:

- Integrated Planning: Early collaboration among designers, manufacturers, and contractors is crucial for optimal tendon placement and efficient tensioning processes.

- Precision Equipment: Using calibrated tensioning tools and monitoring systems is vital for applying exact forces and preventing structural inconsistencies.

- Rigorous Quality Control: Routine inspections, both at the factory and on-site, are essential to maintain high safety and performance standards.

- Skilled Team Training: Investing in proper training for field teams on the fundamentals and management of post-tensioning significantly improves project outcomes.

The Future of Post Tension Slab

As construction evolves, the role of post-tension slabs will continue to grow. Innovations like smart tensioning systems and sustainable materials are making this method even more accessible and efficient. Understanding post-tension slabs today will position professionals to lead tomorrow’s most advanced construction projects.