Modular technology and custom-made precast solutions for the client Duhalde

Moldtech has successfully completed a large-scale project in France with Duhalde Industries, specializing in the production of PAC4UF transformer substations. The objective: to design and supply an automated production line for the manufacture of reinforced concrete transformer substations in compliance with the very strict local regulations. This project strengthens Moldtech’s position as a provider of comprehensive, customized, high-tech solutions in the European precast sector.

Transformer substations play an essential role in medium- and low-voltage electrical infrastructure, providing a safe, resilient, and regulatory-compliant environment for the installation of transformers, medium-voltage switchgear, and auxiliary equipment. Their presence is common in industrial facilities, residential areas, agricultural operations, solar farms, and wind turbines, requiring versatile, reliable, and efficient construction solutions. Duhalde Industries was looking for precisely that: a production line capable of covering different configurations with high technical standards and a production capacity of 1,200 units per year.

To meet this need, Moldtech designed and supplied a state-of-the-art production line, integrating all production systems into a continuous, automated, and safe process. The new industrial plant, a modern 5,000 m² building, is equipped with the necessary equipment to manufacture strong and safe HTA/LV sheds: 3D moulds, covers, slabs, and more. Duhalde Industries operates completely autonomously thanks to its precast concrete plant. The production system is kept under control, from order receipt to delivery anywhere in France.

- Dimensions: 3.6 m (L) x 3.1 m (W) x 2.4 m (H).

- Use: Comprehensive manufacturing of prefabricated transformer substations using a single concrete casting process.

- Technical characteristics:

- Modular design allows adaptation to different configurations.

- High dimensional accuracy, facilitating the subsequent assembly of doors, grids, frames, and electrical systems.

- Efficient opening and closing system, designed to optimize formwork removal and reduce waiting times between cycles.

- Robust, reinforced steel structure capable of withstanding intensive production cycles.

- Safety elements to protect operators during handling and maintenance.

Operational advantages:

- Significant reduction in production time per shed.

- Uniformity in finishes and dimensions.

- Greater durability and ease of maintenance.

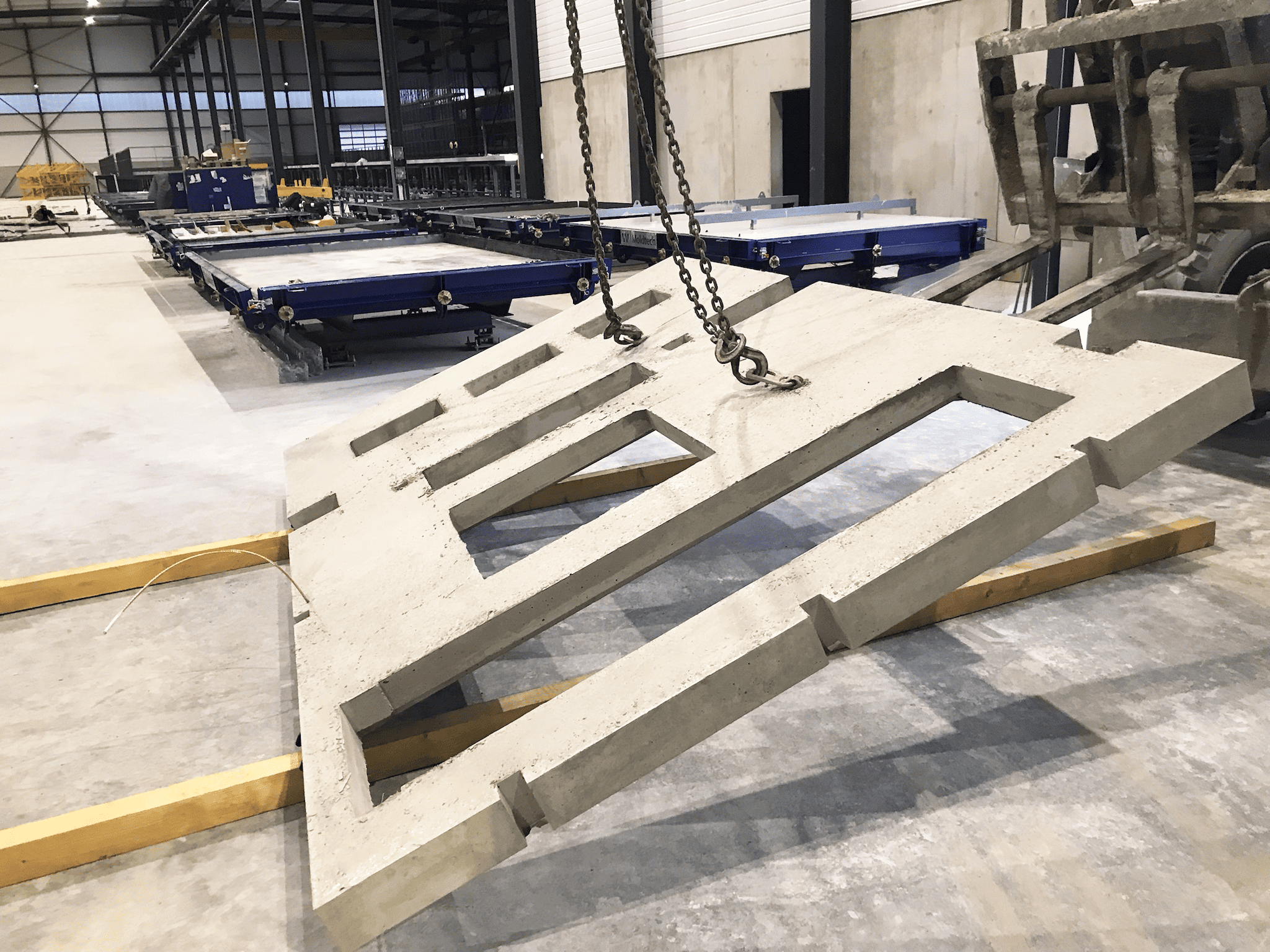

- Fixed tables for sheds slab panels and roof slabs (10 units)

Lay-out:

- 5 fixed tables for the production of sloped roof slabs.

- 5 fixed tables for the production of intermediate slabs with slopes according to regulations.

- Use: casting of flat elements complementary to 3D structures.

- Technical characteristics:

- Work with different slab thicknesses, adapting to project requirements.

- Smooth surface for an excellent surface finish.

- Calibrated geometry to ensure a perfect fit in the final assembly.

Operational advantages:

- Versatility for different types of sheds.

- Production in parallel with 3D moulds, increasing the plant’s total capacity.

Use: Safe handling of three-dimensional precast elements after demolding and before installation.

This auxiliary equipment plays an essential role in the plant, allowing complete precast 3D elements to be rotated from their molding position to their final orientation for installation on site. Its use is especially important in cases where the casting position does not coincide with the assembly position, making safe and precise rotation necessary to avoid risky crane manoeuvres.

The turner supplied for this project is composed of two 90° modules that, acting sequentially, allow a complete 180° rotation. It operates using telescopic hydraulic cylinders connected to a hydraulic power unit and is designed to support up to 50 tons, making it the largest capacity manufactured by Moldtech to date.

- Technical characteristics:

- Hydraulic system driven by telescopic cylinders.

- Full 180° rotation with two 90° steps.

- Maximum capacity: 50 tons.

Operational advantages:

- Ensures safe handling of large volumes.

- Improves ergonomics and reduces plant risks.

- Facilitates the transition of elements between stages without tandem cranes.

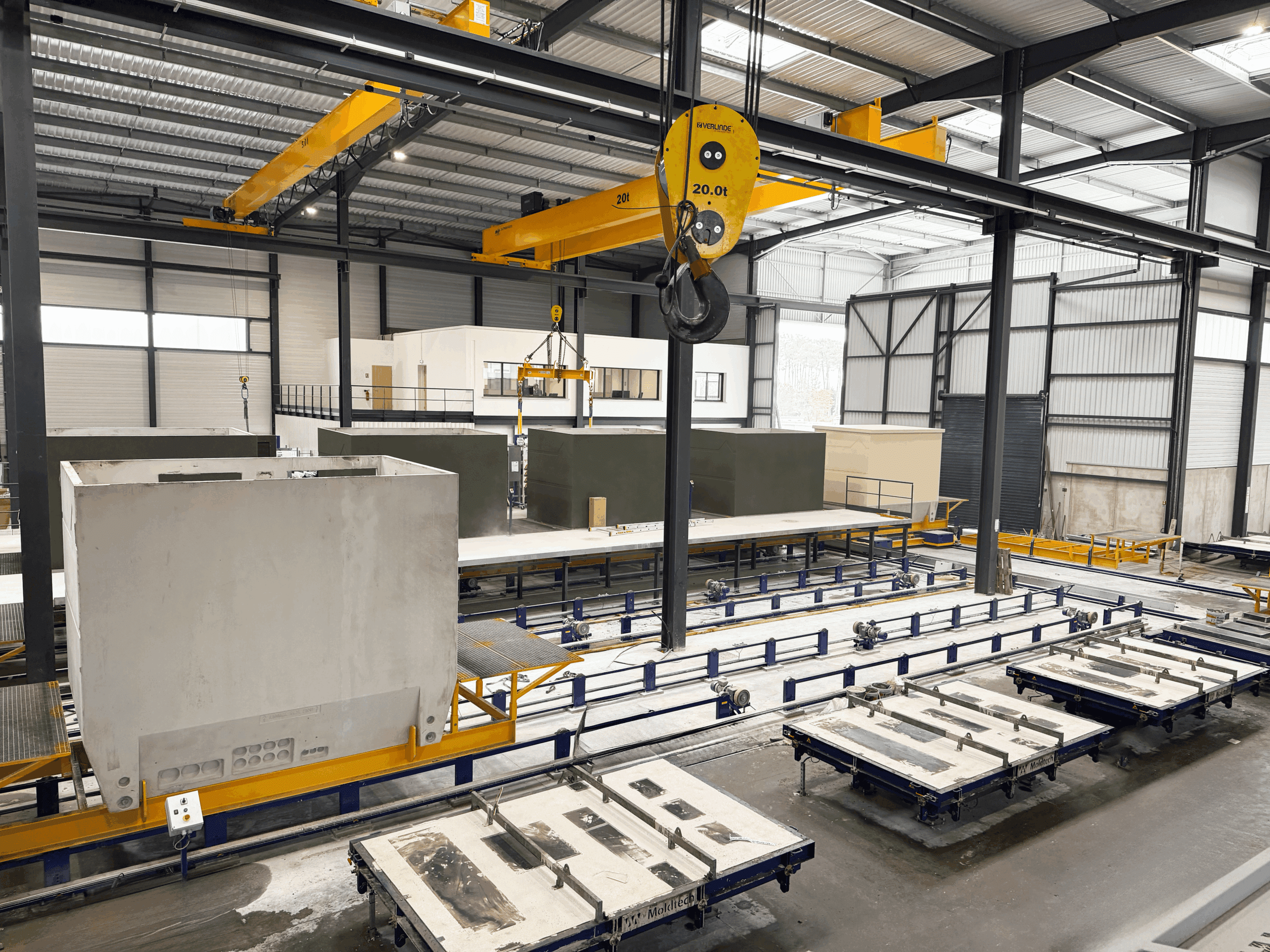

- Carousel line for final assembly

Use: Sequential assembly of precast elements, execution of finishing works and electrical installations.

The CAROUSEL system was designed as a solution for the serial production line of precast concrete transformer sheds. Its main function is to facilitate the entire manufacturing process, from obtaining the structural elements using specific moulds to the final finishing phases and installing the electrical components.

This system allows for efficient and safe handling of precast elements during the various stages of the production process, ensuring operational continuity, final product quality, and optimized cycle times.

The system was designed according to the client’s specifications to operate under the following conditions:

- 36 working stations

- Shed size: 3.6 x 2.37 x 2.35 m

- Pallet dimensions: 5.32 x 2.37 m

- Precast elements processing area

- Assembly area

- Storage area

The carousel features main, secondary, and individual control panels, as well as centralized control software that allows for management and control of the entire process.

- Technical characteristics:

- Closed-loop modular layout.

- Fixed positions for each assembly phase: placement, fixing, connection, and inspection.

- Structural support and guidance system to ensure precise alignment.

- Integration with auxiliary handling systems.

Operational advantages:

- Reduced assembly times.

- Greater control over process traceability.

- Standardized assembly with the ability to adapt to different configurations.

Comprehensive solution adapted to market demands

This project reflects a 360° approach to precast engineering. Moldtech not only provided the equipment but also supported Duhalde in setting up an efficient, safe, and mass-produced plant. All equipment has been designed based on principles of functional compatibility, enabling smooth operations from start to finish.

Daily manufacturing capacity is increased thanks to the ability to perform simultaneous processes. While the 3D moulds work on the main structure, the fixed tables produce ceiling and floor slabs in parallel, which are then assembled using the carousel, completing the cycle with efficiency and precision.

Furthermore, the robust design of all the equipment ensures a long lifespan, easy maintenance, and safe operation even during long production shifts. This type of solution is especially relevant in today’s precast context, where competitiveness demands maximum efficiency, regulatory compliance, and adaptability.

Technical and personalized approach

Each component of the system has been designed with engineering criteria applied to actual plant use. Moldtech worked closely with the Duhalde Industries technical team to adapt the dimensions, anchoring systems, manoeuvrability, and ergonomics to the client’s specific needs.

This customized approach has optimized both the equipment’s performance and the quality of the final product. The transformer substations produced with this line meet French and European standards for structural strength, insulation, durability, and compatibility with standard electrical equipment.

The French precast market: an evolving environment

France currently represents one of the most dynamic markets in Western Europe in terms of electricity grid modernization and energy transition. The growing demand for infrastructure associated with renewable energy, rural electrification, and new construction regulations have driven the adoption of precast solutions that guarantee rapid execution, technical traceability, and structural strength.

In this context, the use of prefabricated transformer substations has become an increasingly valued alternative for electricity distribution companies, construction companies, and energy project developers. The ability to manufacture in-house, under controlled conditions, and deliver ready-to-install solutions reduces construction times, logistics costs, and operational risks in the field.

Therefore, this project not only responds to a specific need of the client, Duhalde Industries, but also aligns with the structural trends of the French market: industrialization of the sector, automation of the construction process, and a focus on sustainable and adaptable solutions.

Conclusion

The project developed with Duhalde Industries not only represents a high-level technical solution, but also an example of business collaboration focused on efficiency and technological innovation in the field of construction industrialization. Moldtech once again demonstrates its ability to integrate engineering, production, and customer support into a comprehensive offering aligned with the challenges of modern precasting.

With this new facility in France, Moldtech consolidates its expansion into the European market and reaffirms its commitment to developing precast technologies tailored to each client, each application, and each production environment.

At Moldtech, we don’t strive to be better. We strive to be unique.