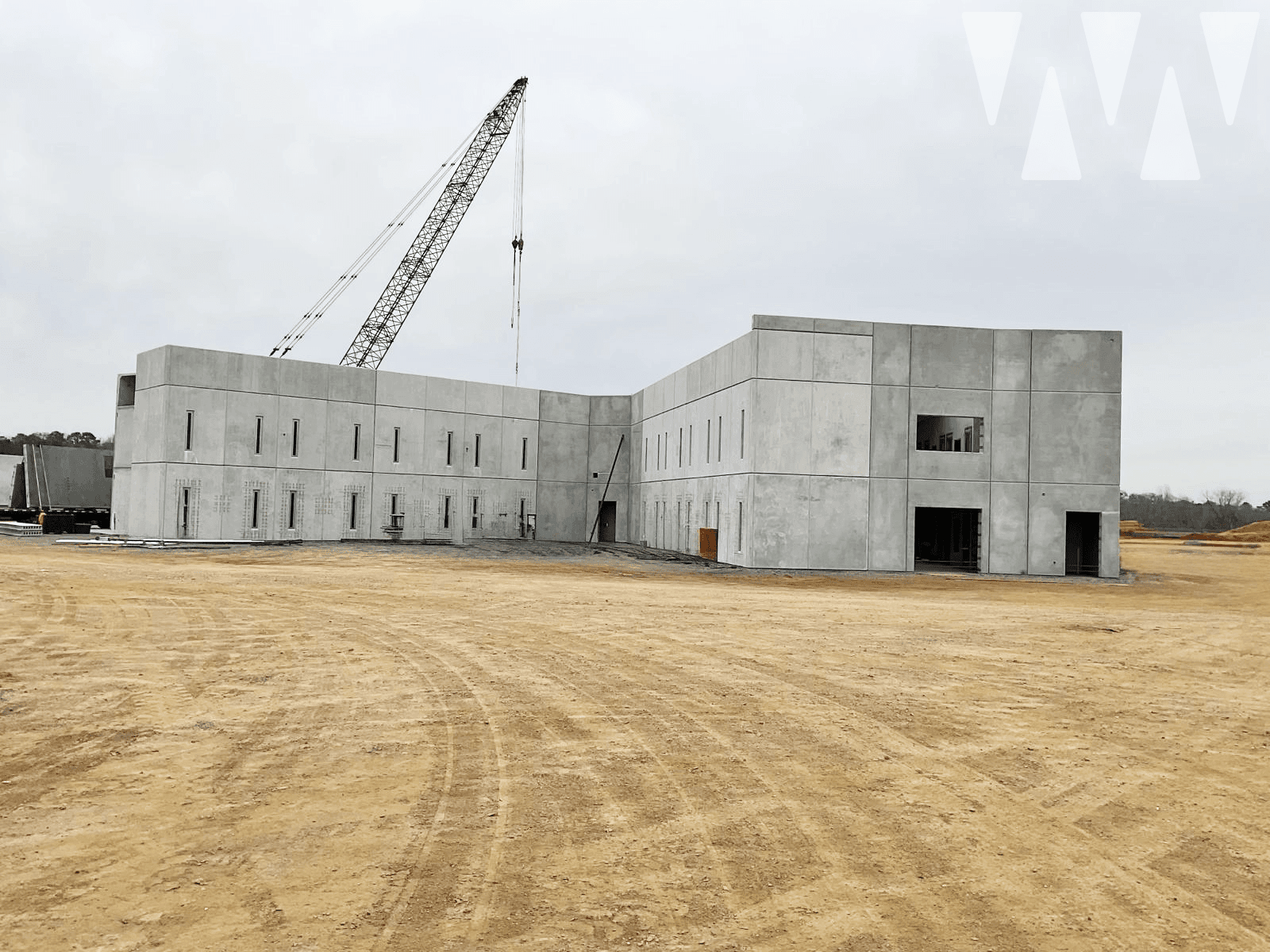

The synergy between technology and efficient methods redefines prison facility construction in Alabama, highlighting an innovative approach and exceptional results

Within the world of precast, Moldtech, based in Spain, has become a leading player in the range of 3D moulds for modules of different sizes.

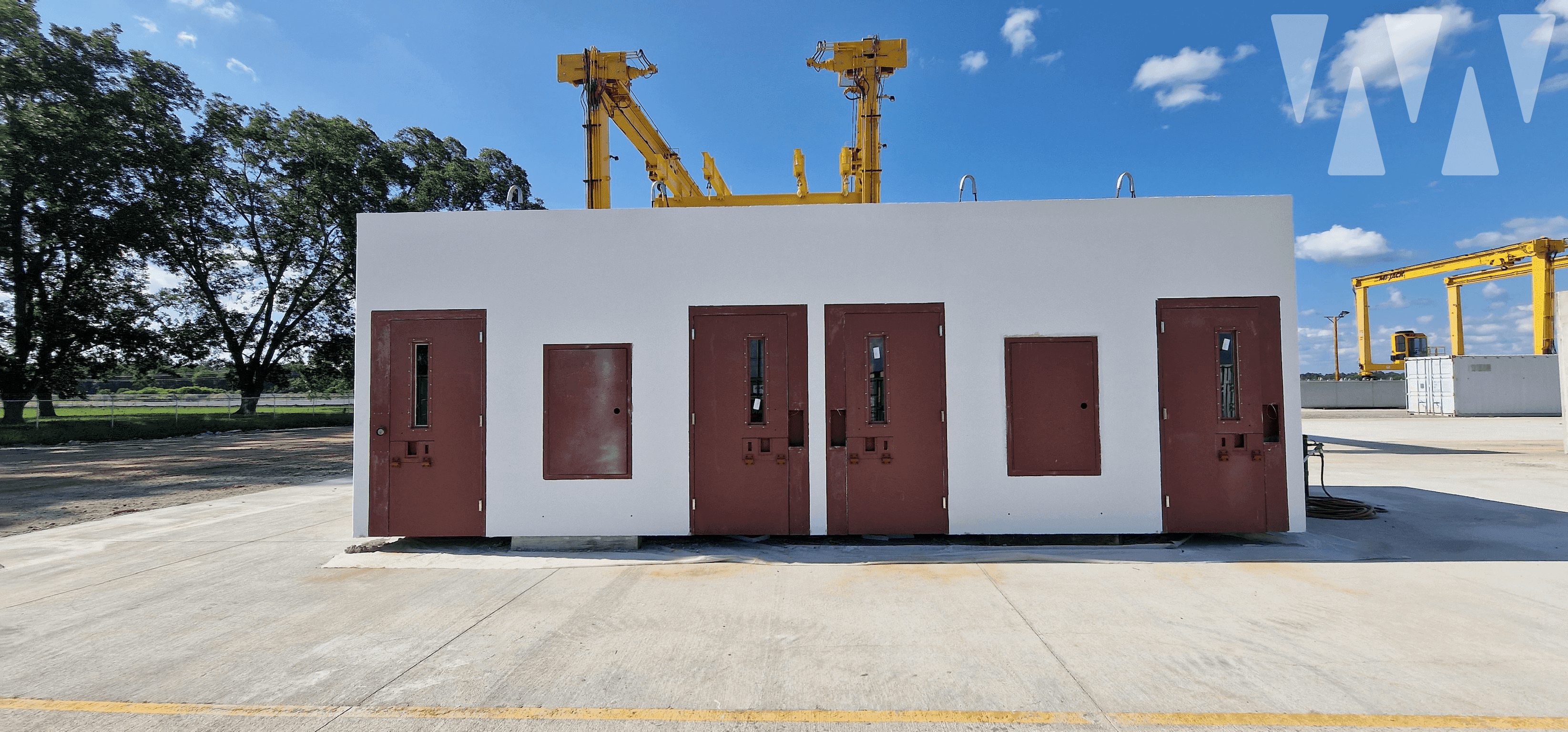

For a project to build a macro prison in Alabama with different types of cells (standard cells, cells for medical use, cells for the disabled, etc.). Moldtech designed hydraulic moulds that can make 2 or 4 cells at the same time. The client was a leading provider of detention services and products globally, specializing in the manufacture, distribution and installation of institutional detention equipment and products for both domestic and international clients and with an extensive experience in the construction of prefabricated modules.

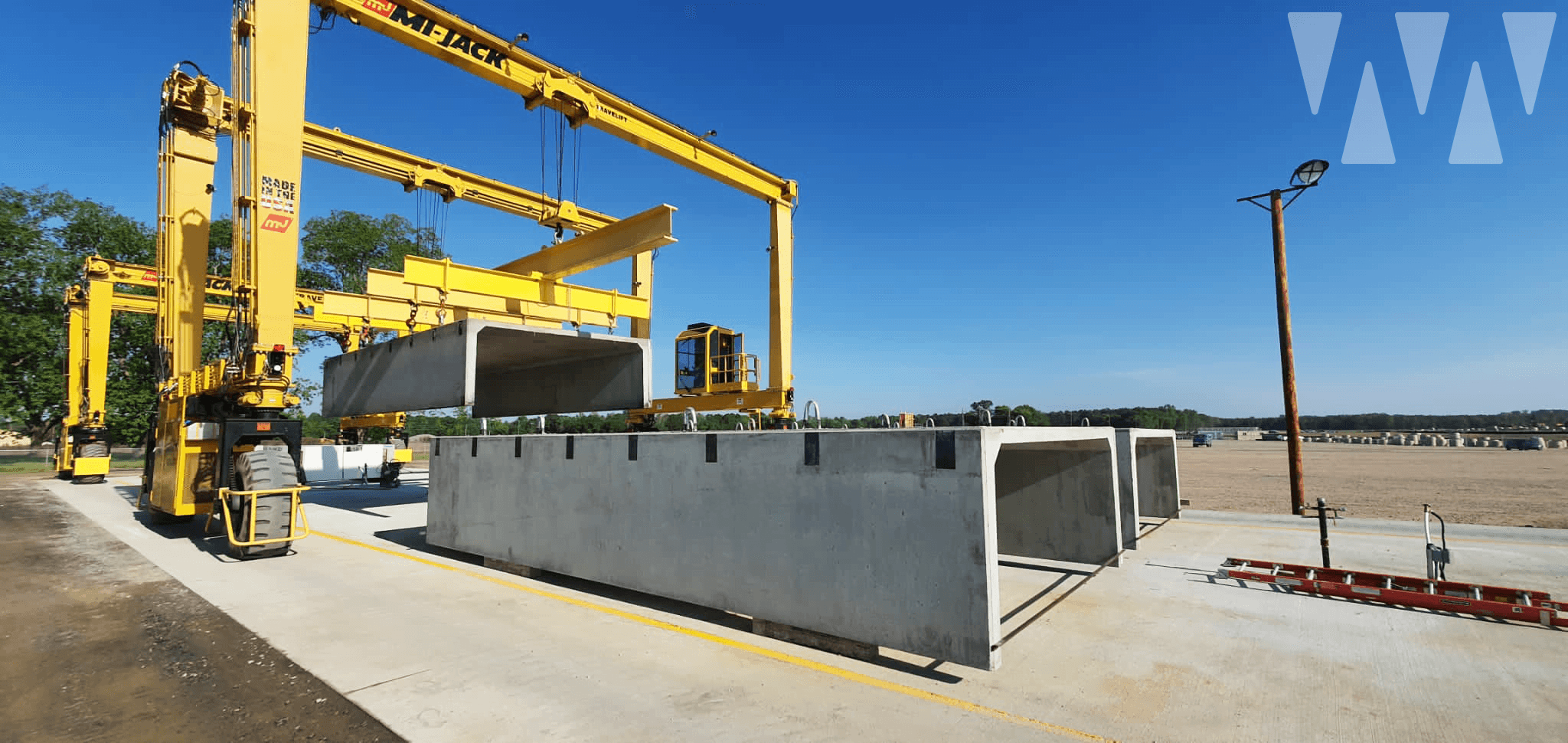

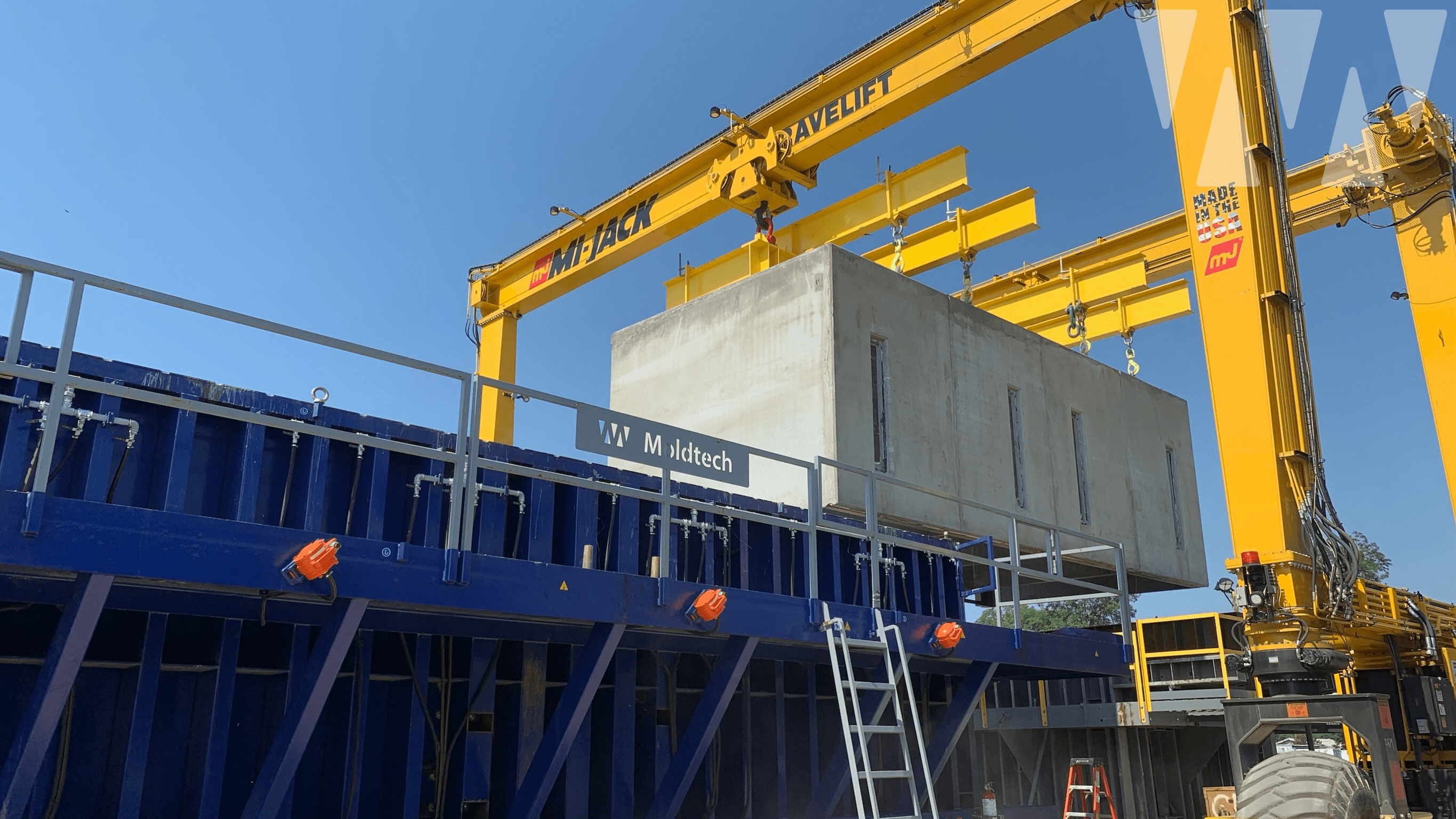

Industrialized construction using 3D modules has been key in this project, highlighting its advantages in terms of efficiency, speed and quality compared to traditional construction methods. Moldtech has played a pivotal role in providing a one-stop supply that includes advanced 3D molds designed for prison cell manufacturing.

The scope of supply includes:

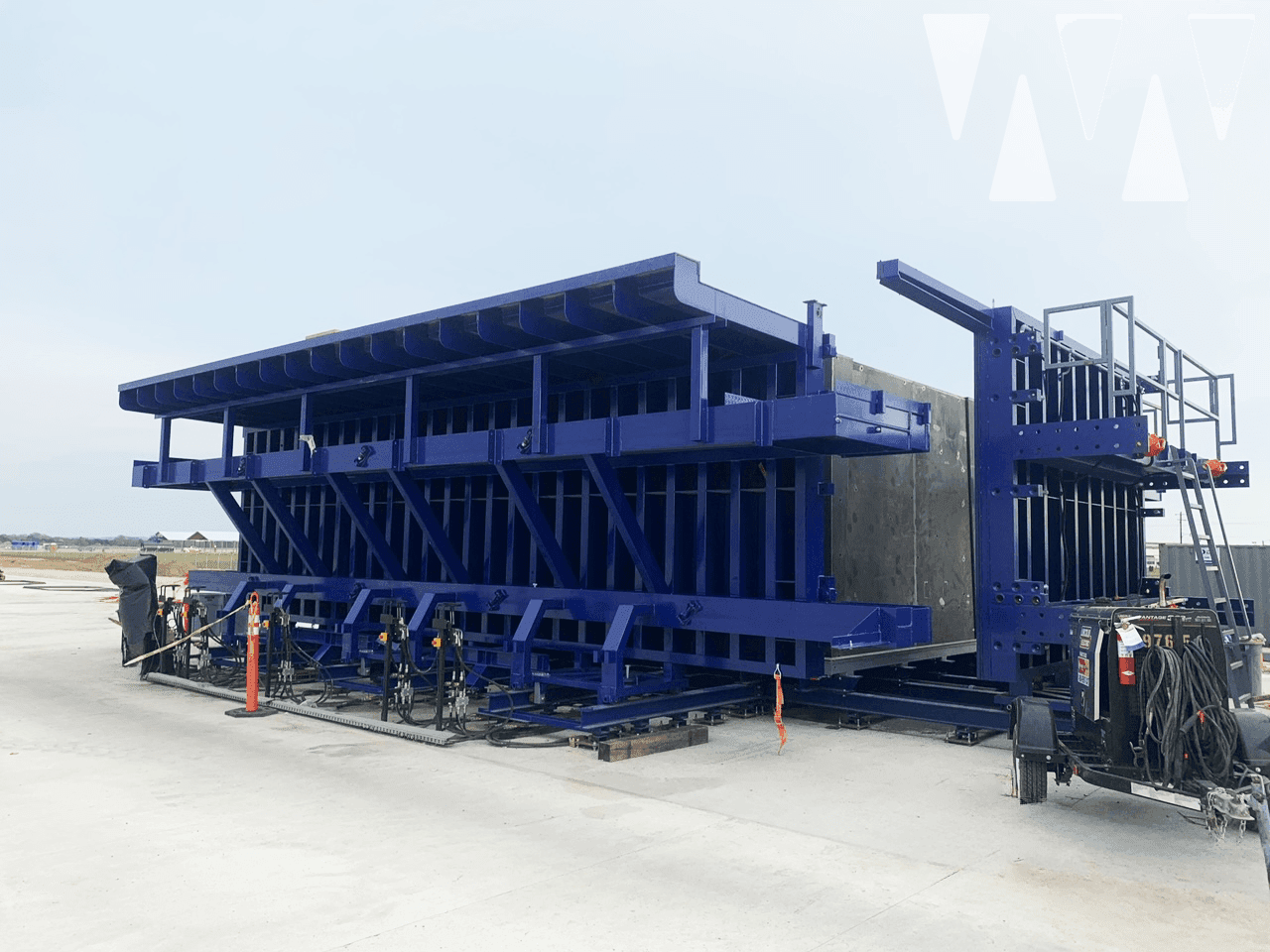

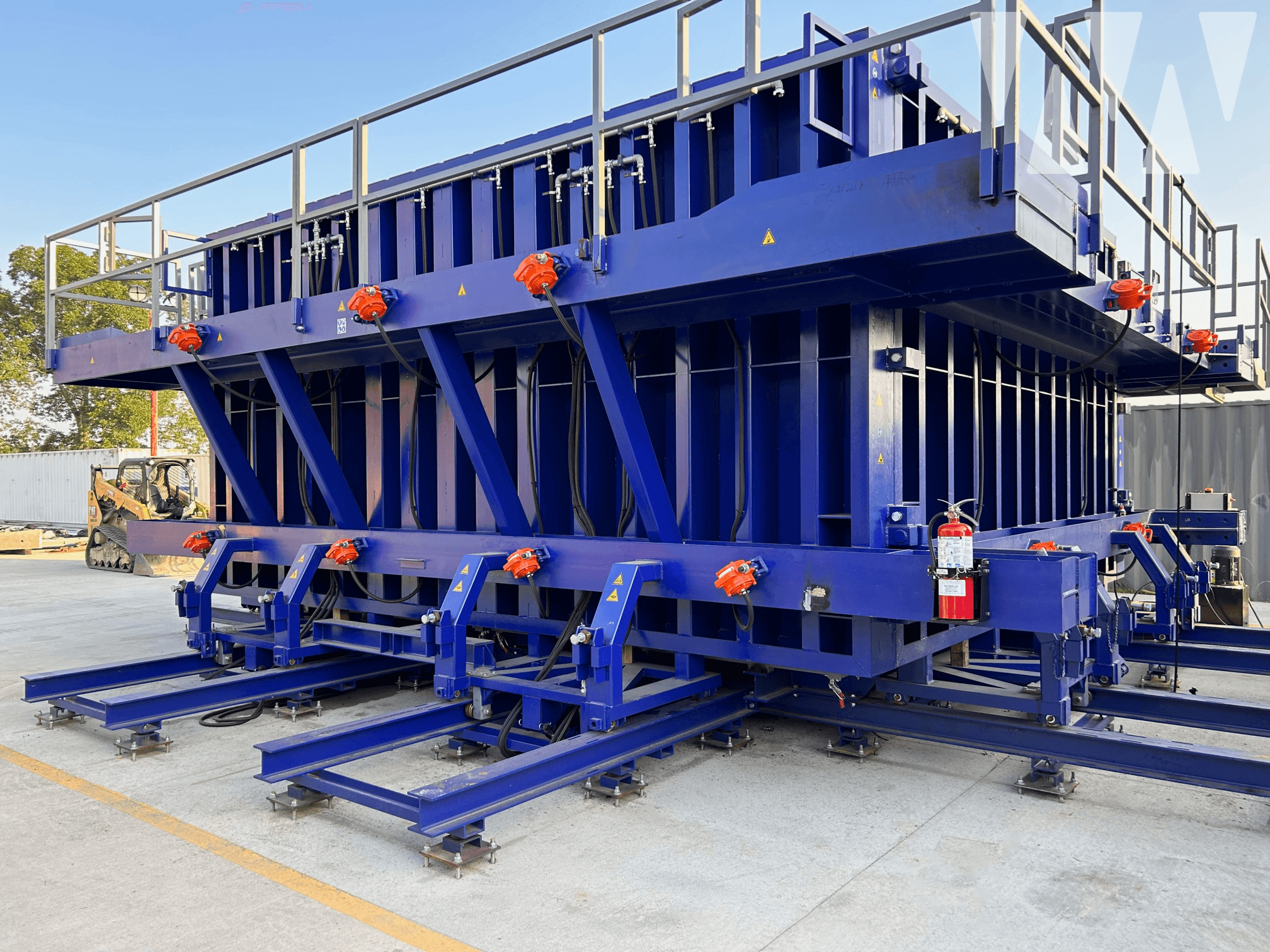

- 1 MOULD TO MANUFACTURE 4 STANDARD CELLS (QUADCELL)

- 1 MOULD TO MAKE 4 CELLS FOR HANDICAPPED PERSONS (QUADCELL)

- 2 DOUBLE HEALTH CARE MOLDS

- 1 DOUBLE RHU MOULD (RESTRICTED HOUSING UNIT)

- 1 PLENUM MOLD TO COVER 4 CELLS

- 2 PLENUM MOLD TO COVER 2 CELLS

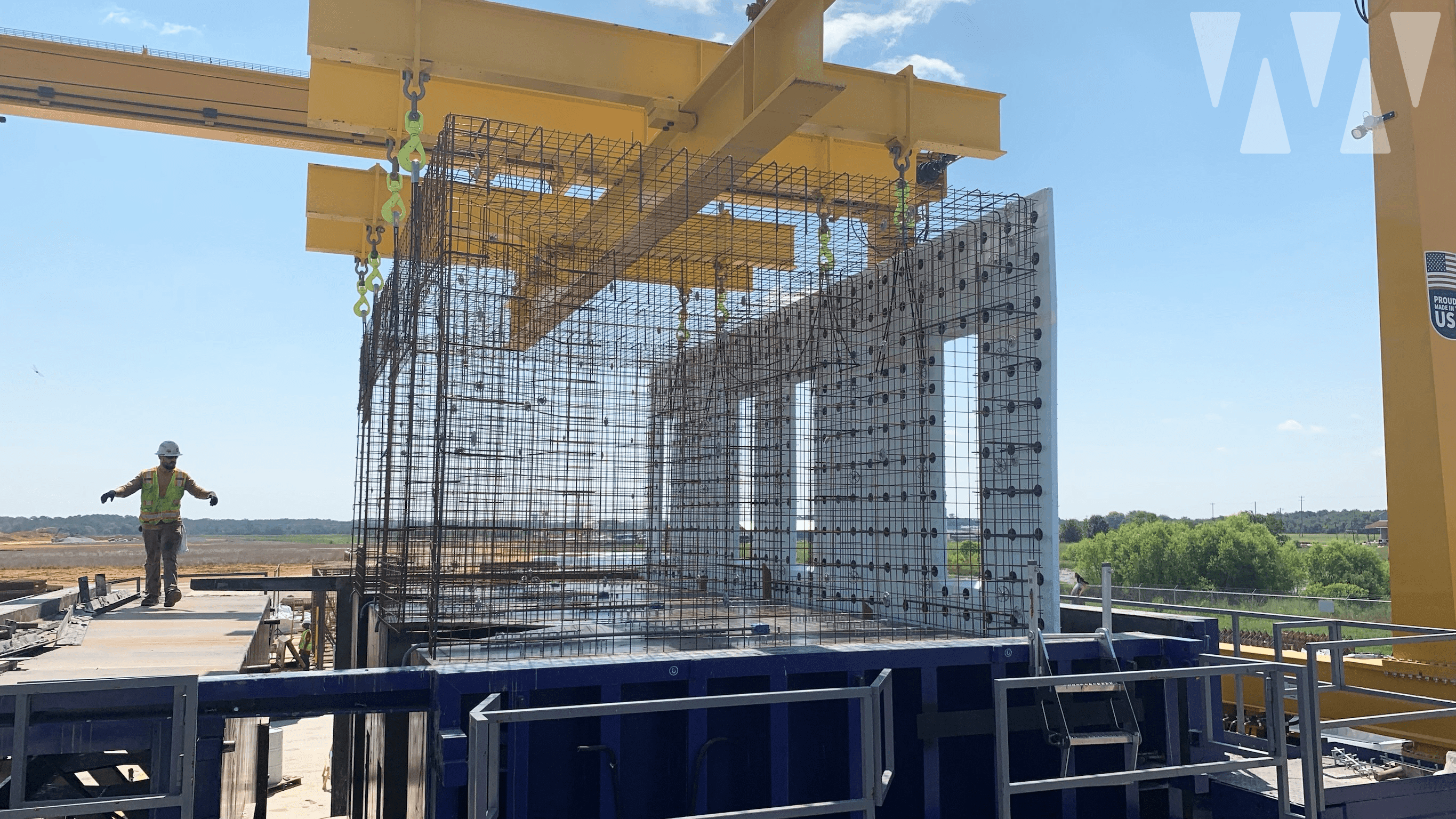

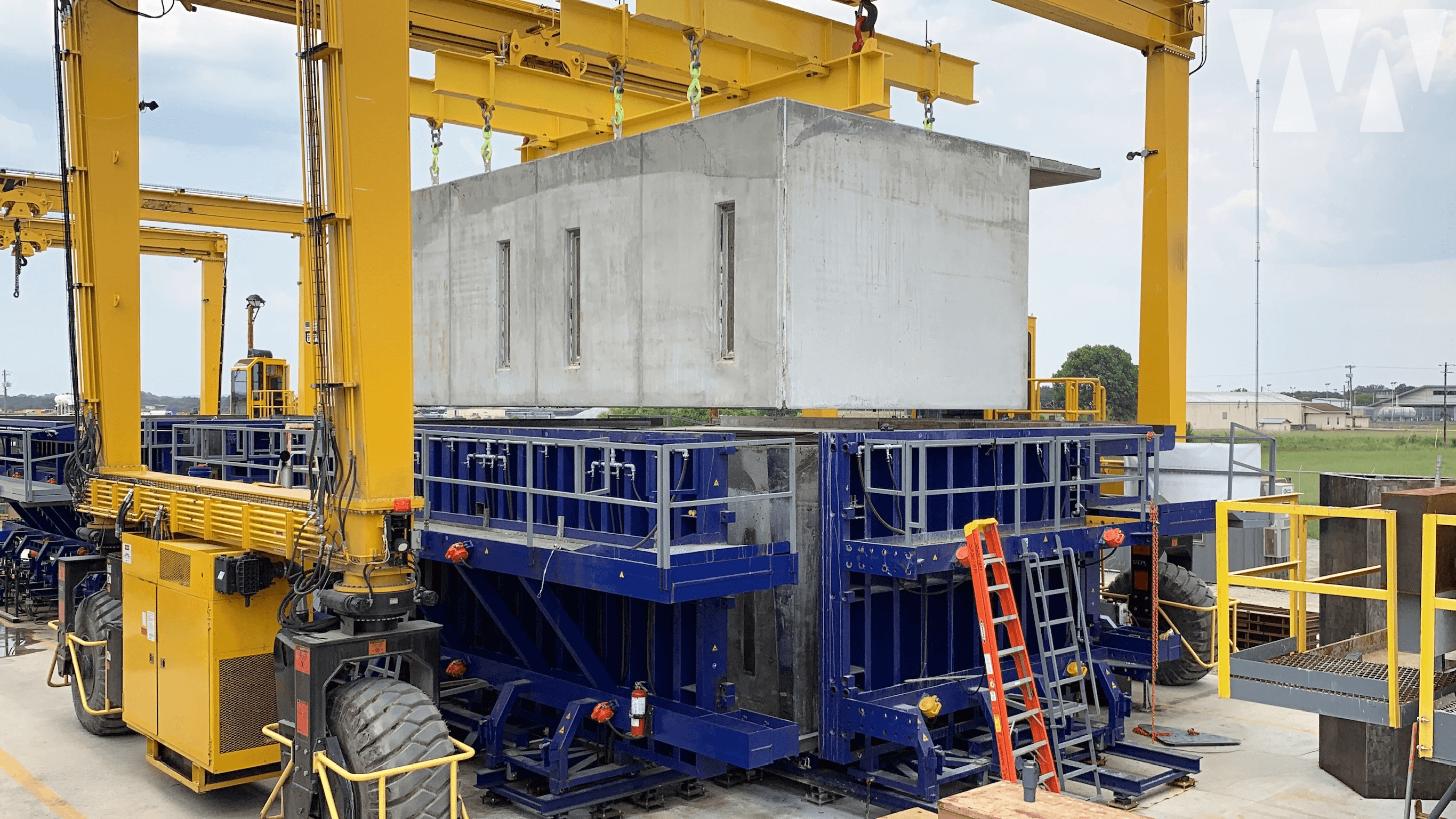

The installed moulds allow a multitude of adjustments for different parts, such as wall thicknesses, module height, protruding reinforcements or the window and door position. Moreover it ensures a very efficient manufacture due to its fully hydraulic demoulding system which makes it possible to optimize quality and productivity.

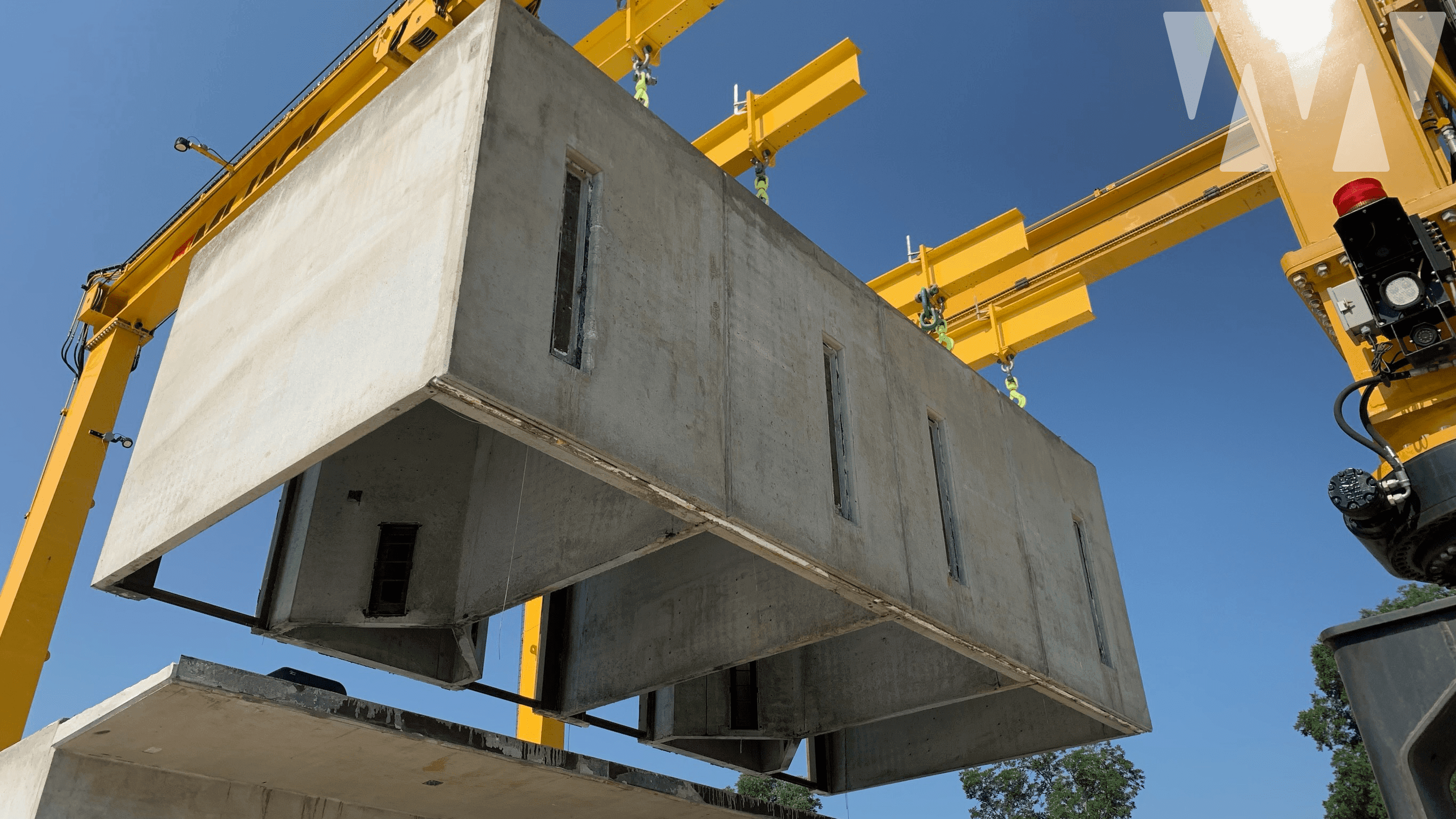

The exterior walls of the mould are opened by hydraulic cylinders, allowing the formwork of doors and windows to be removed at the same time. The core can be contracted with a hydraulic system, allowing the demoulding of the monolithic 3D cells with straight walls in record time.

At Moldtech we are highly specialized in the design and manufacture of flexible moulds for 3d modules (PPVC). Our modular moulds allow to adjust measurements in width and length of the modules within the same project and for future projects with minimal additional investment.

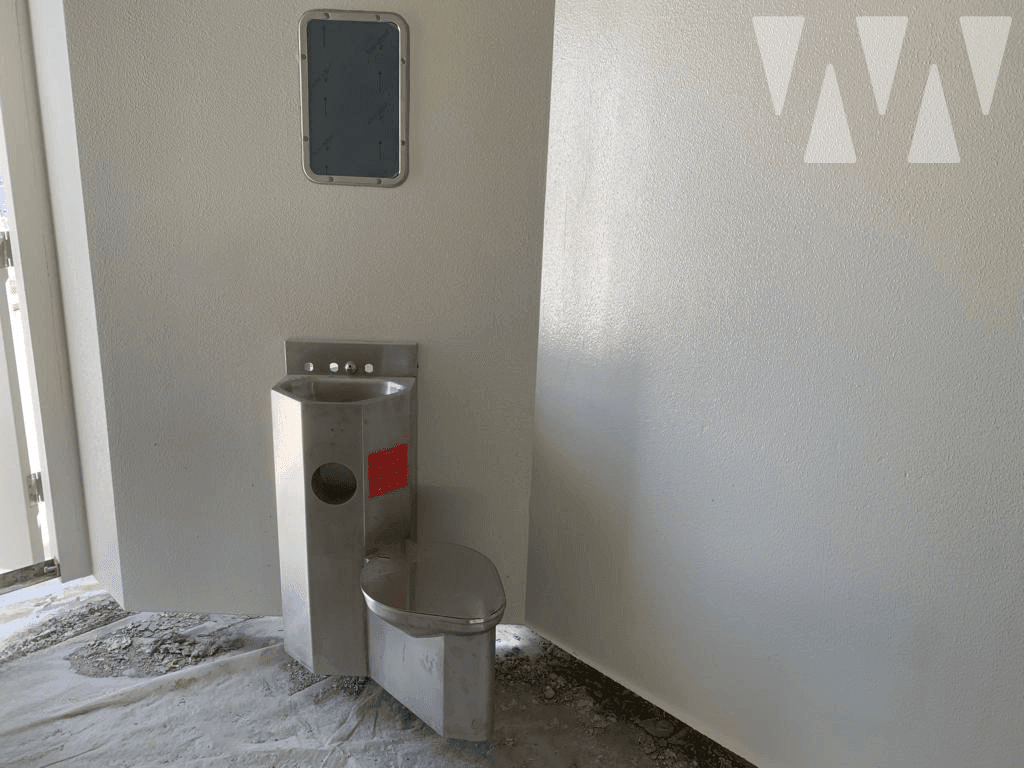

After removing the three-dimensional concrete modules from the moulds, the finishing phase is carried out. This involves the incorporation of installations such as light fixtures, as well as the installation of the furniture. All of this is done according to a previously designed scheme where workers and technicians execute repetitive tasks. This methodology ensures quality verification at every stage of the process, resulting in prison cells with an exceptional level of quality.

Optionally, these moulds can also include an efficient heating system for accelerated curing of the modules.

3D moulds allow the creation of highly customized designs; moreover this technology has streamlined the manufacturing process, ensuring the timely delivery of components for the construction of safe and efficient facilities.

In addition to the 3D moulds, Moldtech has supplied 2 manual pouring buckets with a capacity of 7.7 m3 (10 yd3) designed to facilitate the controlled and precise pouring of concrete at the job site. Its high capacity allows the moulds to be filled faster, thus increasing the pace of production.

Moldtech has stood out as a strategic ally for the manufacture of moulds for precast concrete, demonstrating its ability to face diverse challenges and meet the most demanding requirements of its customers.

This success reinforces Moldtech’s reputation as a reliable partner capable of offering optimal solutions for the most rigorous needs of the construction industry.