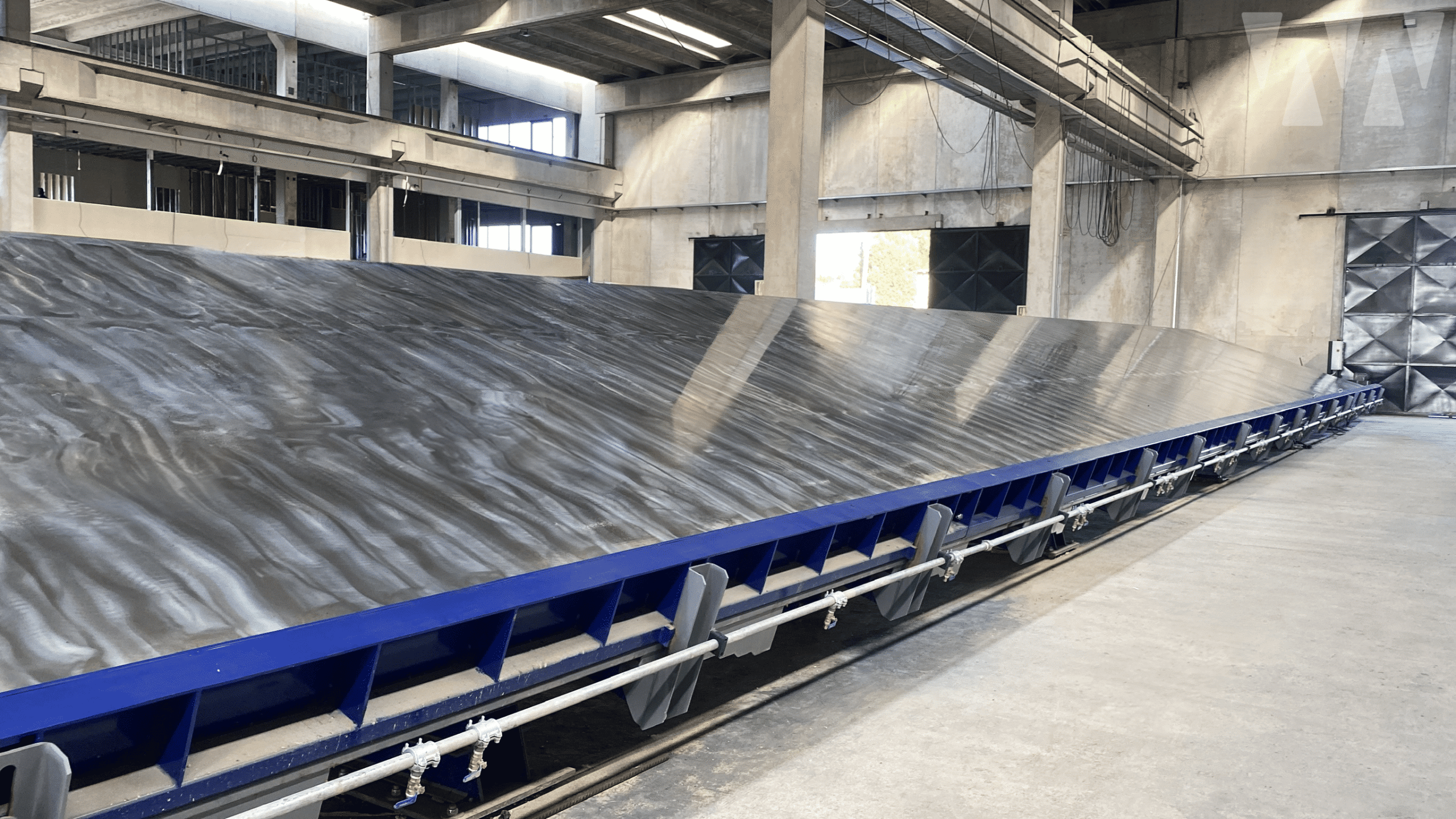

Moldtech is pleased to announce a new international project that consolidates our presence in Latin America: the supply of a large tilting table in Uruguay for the production of non-prestressed precast concrete panels.

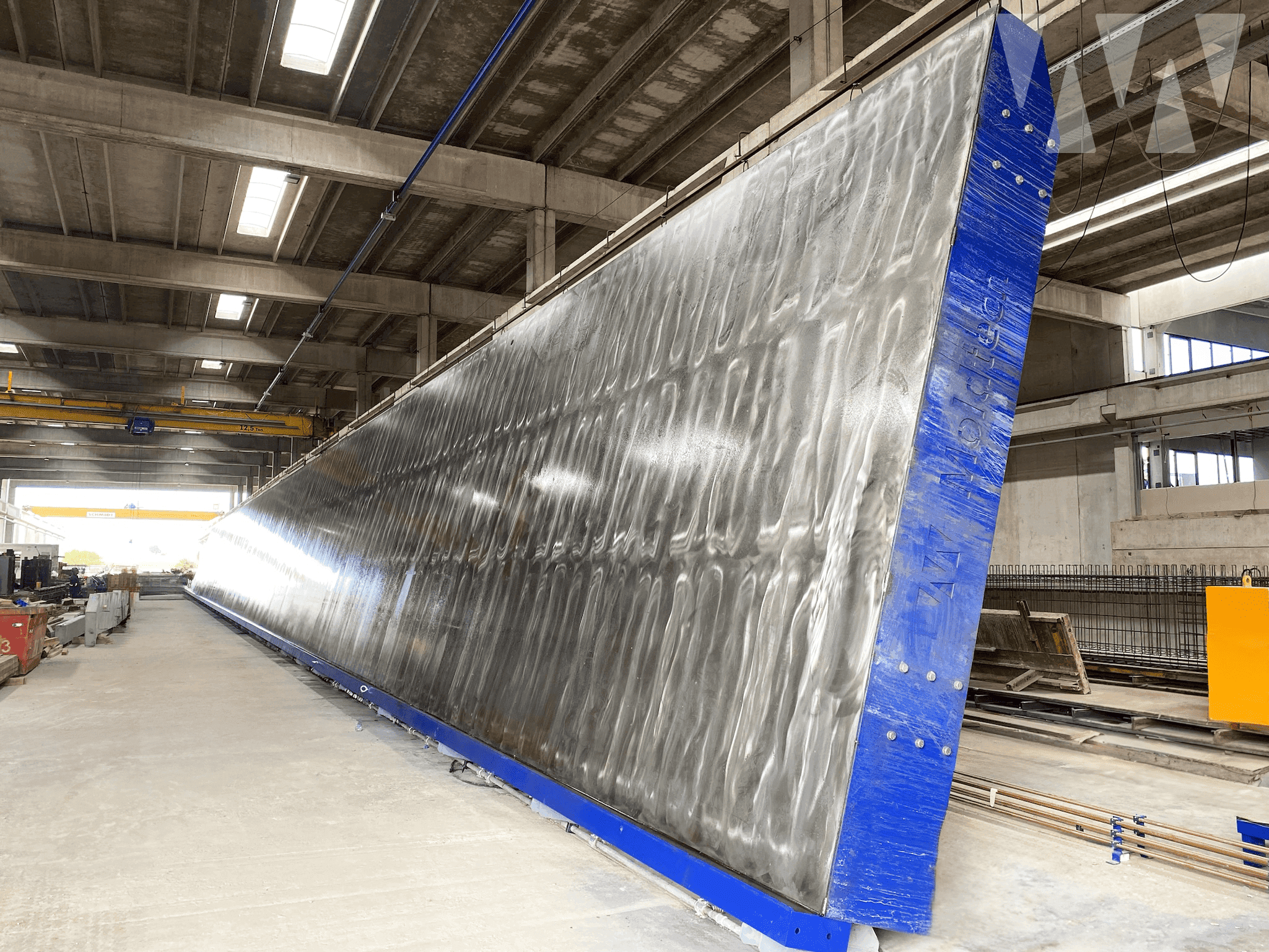

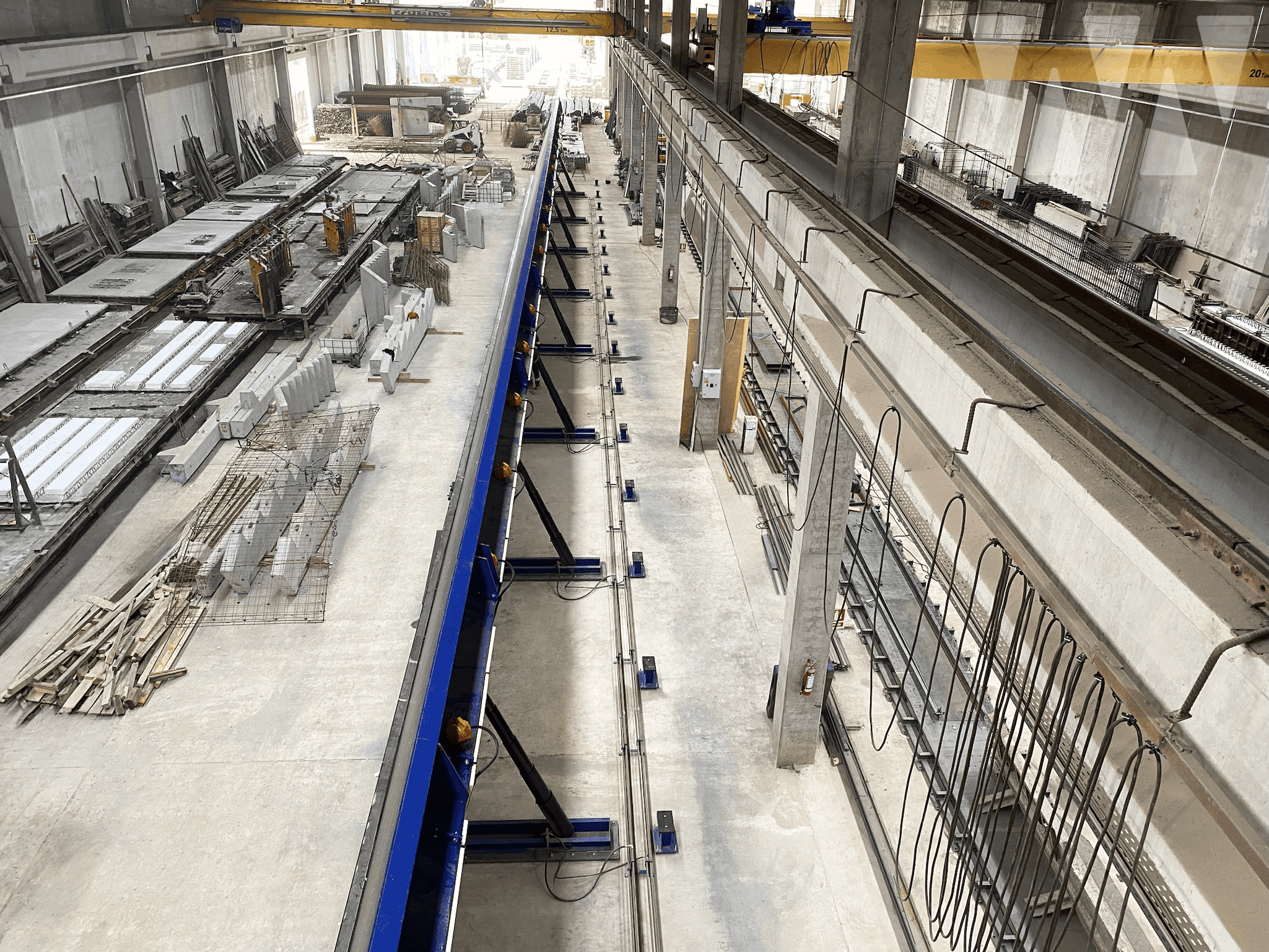

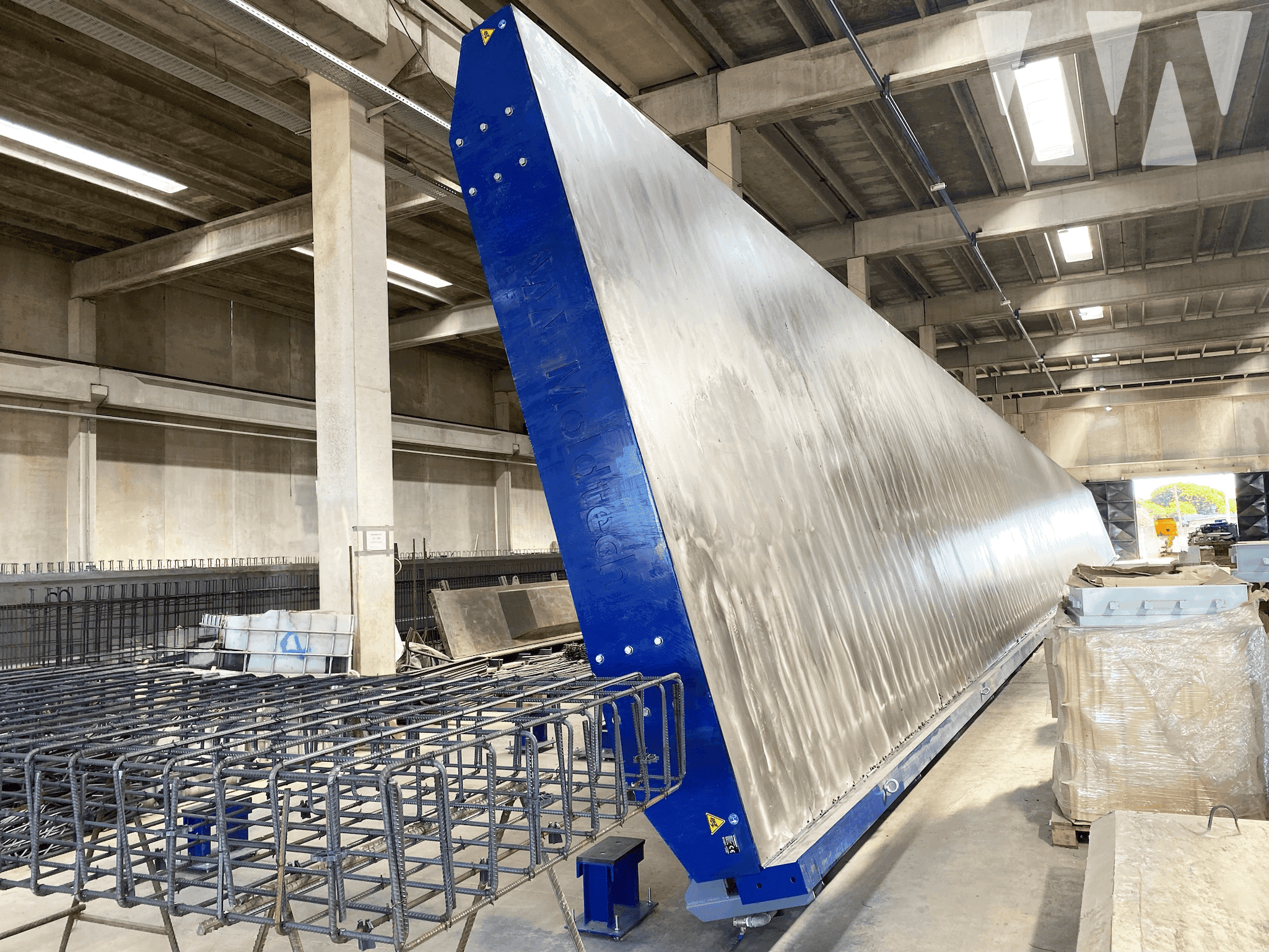

The installation, 60 metres long by 4 metres wide, has been designed to manufacture panels with variable lengths between 3 and 4 metres and adjustable thicknesses from 100 to 250 mm. This state-of-the-art equipment incorporates technologies that optimise both product quality and production processes.

Its main technical features include:

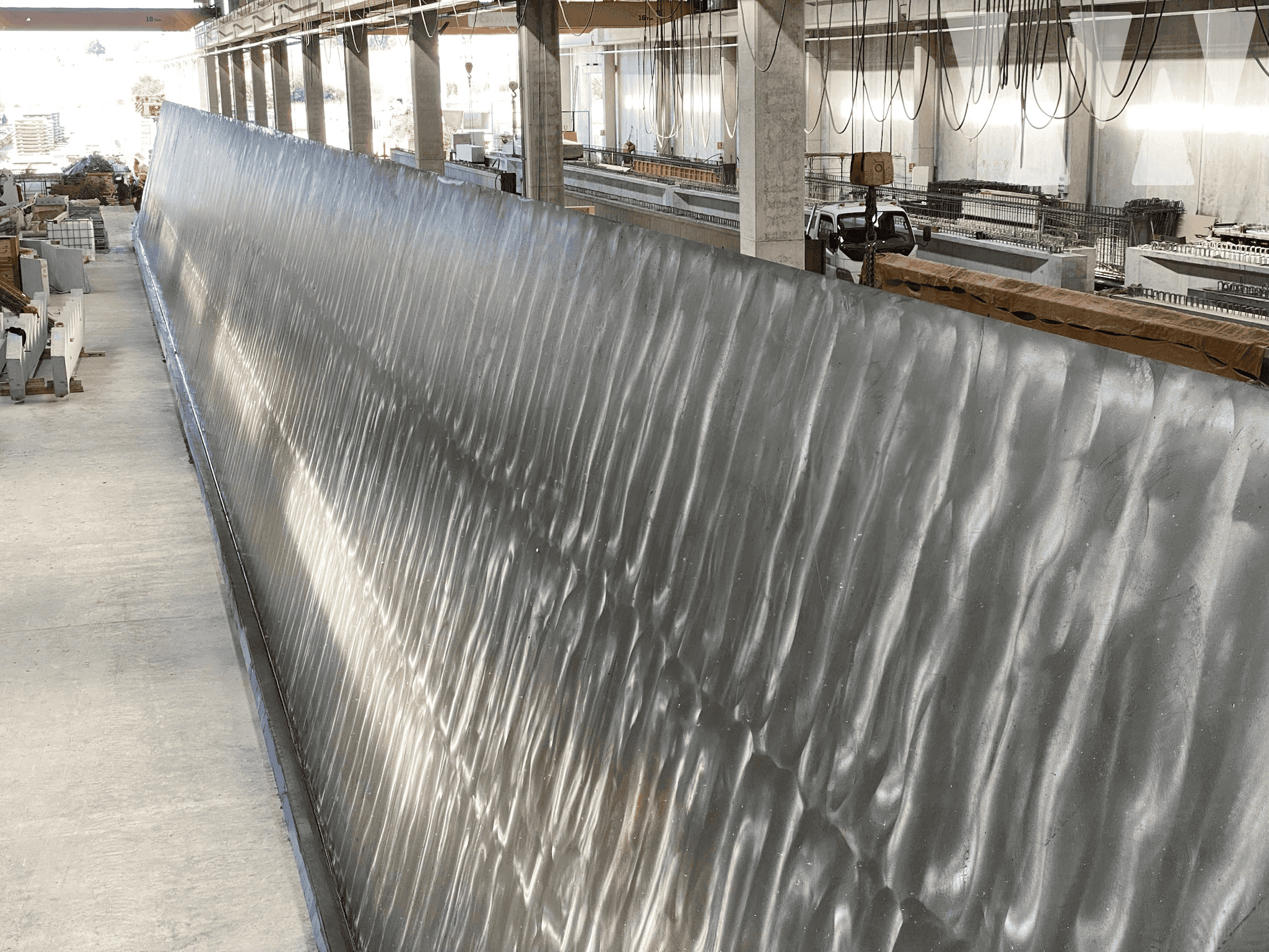

- Pneumatic vibration system, which improves concrete compaction and reduces porosity.

- Integrated heating in the board, which promotes uniform setting and accelerates curing times.

- Hydraulic tilting system, operated by cylinders and a hydraulic power unit, controlled from a main cabinet.

- Height-adjustable lower longitudinal side, which facilitates the production of panels with different thicknesses.

- Supply of 1,800 kg and 900 kg industrial magnets, together with adapted phenolic formworks.

- A laser projection system, which projects the exact design of the panel to be manufactured onto the table surface, allowing operators to precisely position the magnets and separators, optimising preparation time and reducing errors.

This project once again highlights Moldtech‘s ability to develop customised solutions and to meet the technical challenges posed by the industrialisation of construction.

Industrialisation of precast concrete in Uruguay

Our client in Uruguay, with more than 30 years of experience in precast sector, is an outstanding example of how to combine traditional experience in precast concrete with a firm commitment to industrialised processes.

This company, a national benchmark, offers a wide range of precast products for industrial, commercial, residential and infrastructure works, such as beams, walls, pre-slabs, stairs, New Jersey type barriers, elevator shafts and box culverts.

It has also developed a specific line of prefabricated housing, aimed at both social and larger-scale residential projects, with a modern and sustainable approach that prioritises quality and energy efficiency. The company is ISO 9001 certified and has been institutionally recognised for its commitment to innovation and excellence in its processes.

At Moldtech, we are proud to participate in its evolution and to be part of a process that drives faster, safer and more standardised construction in the region.

Magnetic technology for faster production

This project also includes some of our most advanced magnetic solutions, specifically designed to facilitate and speed up the forming of panels in different types of moulds: tilting tables, fixed tables, vertical battery moulds, among others.

We manufacture high-performance magnetic boxes equipped with neodymium magnets that guarantee a firm and precise fixing without the need to drill holes in the board, thus preserving the work surface. Their robust design, with blued box and steel components, protects them against corrosion and gives them a long service life.

Thanks to their versatility, these magnet boxes can be fitted with customised adapters and accessories, making them easy to integrate into any production system. The result is a faster, safer and more efficient assembly that reduces time and increases productivity in the plant.

With projects like this, Moldtech confirms its role as a strategic partner for companies that are committed to the development of precast concrete, offering technology, experience and commitment in each solution.