Moldtech goes on to provide solutions for industrialized construction with its 3D Mold – PBU (prefabricated bathroom unit), designed for the manufacture of prefabricated concrete bathrooms in a single piece, ready to be transported and slotted into place like a perfect puzzle.

This system allows you to optimize construction processes, improve productivity and guarantee a high-quality standard in each module produced.

A mold designed for maximum use

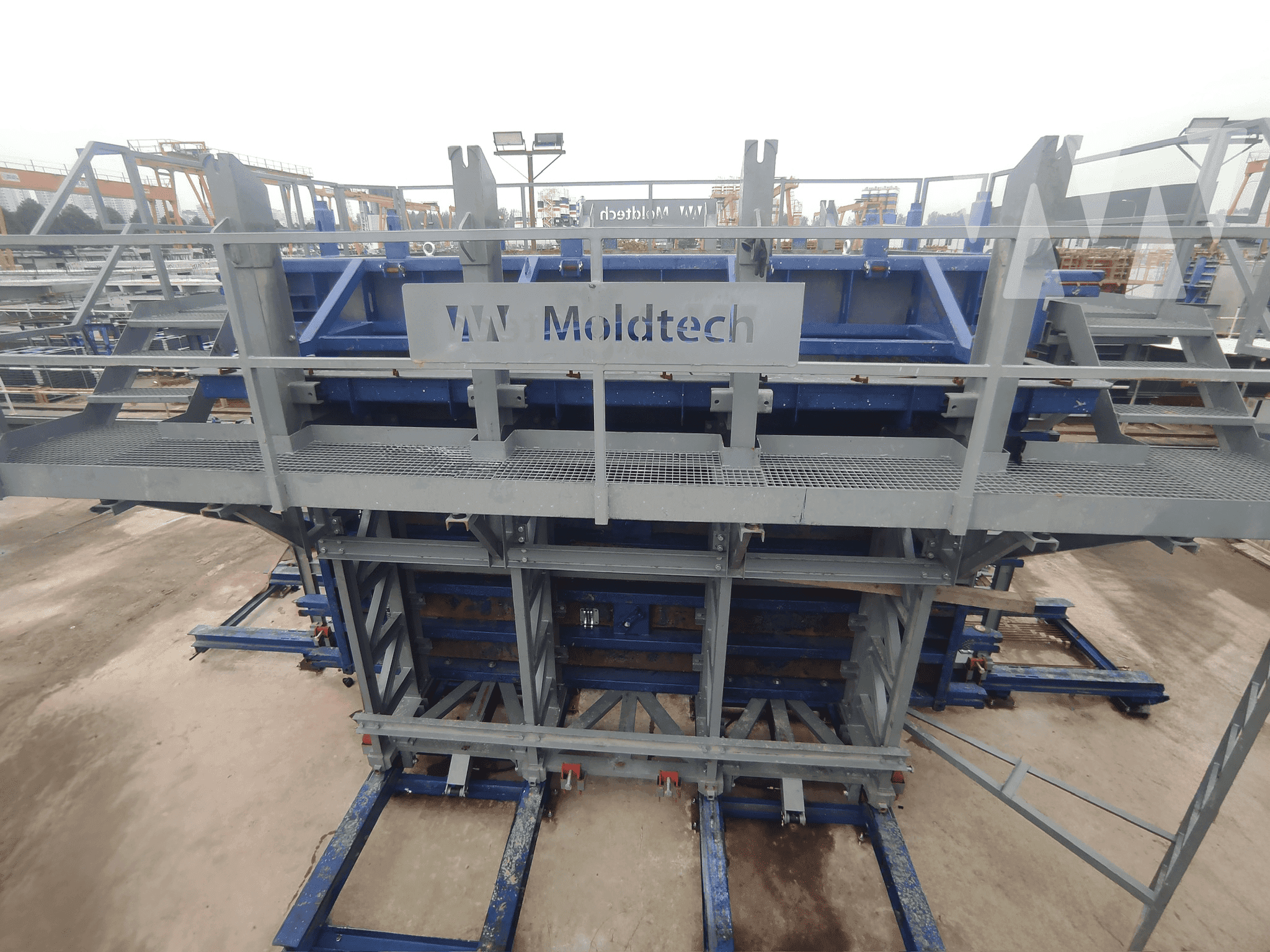

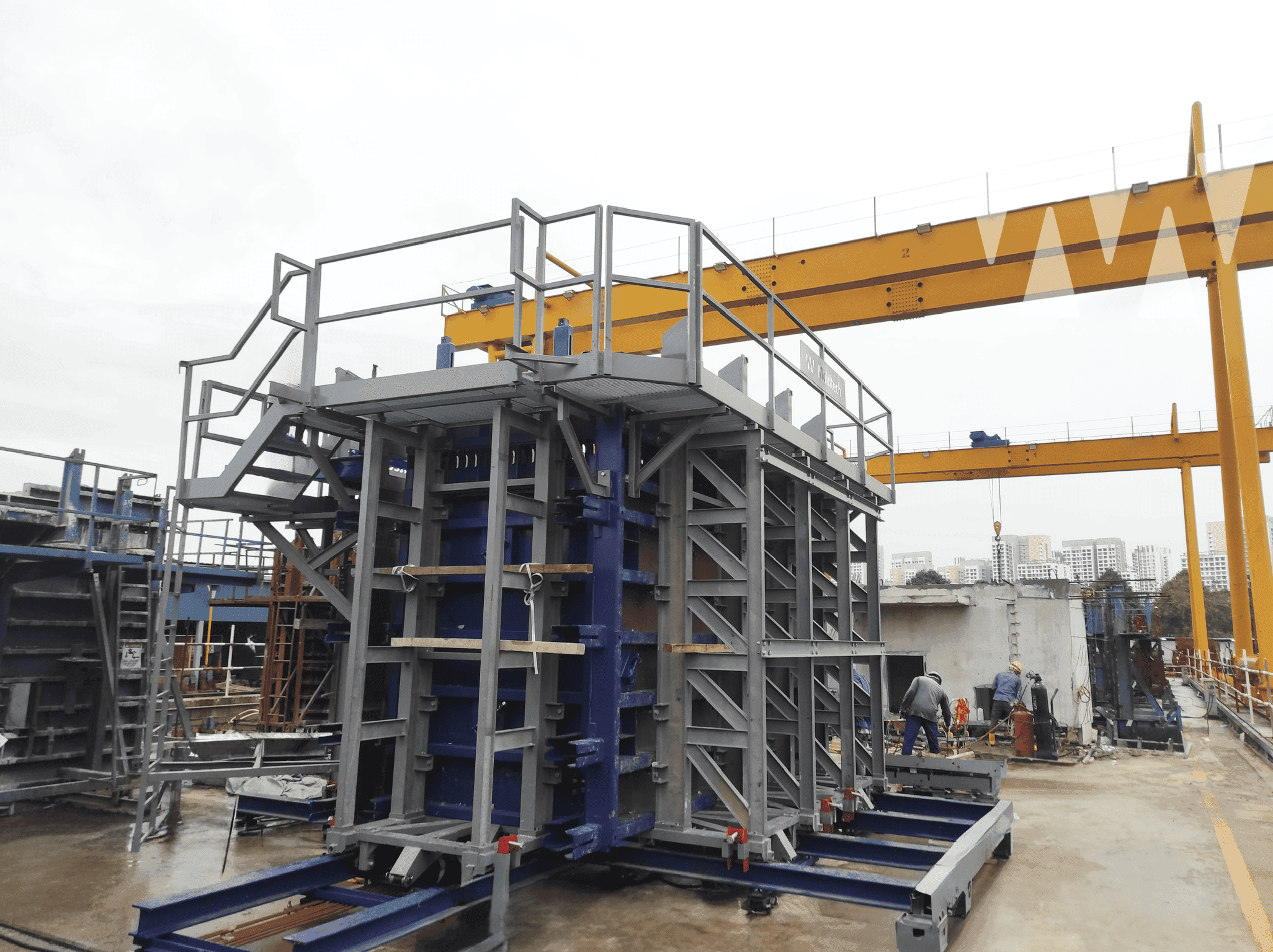

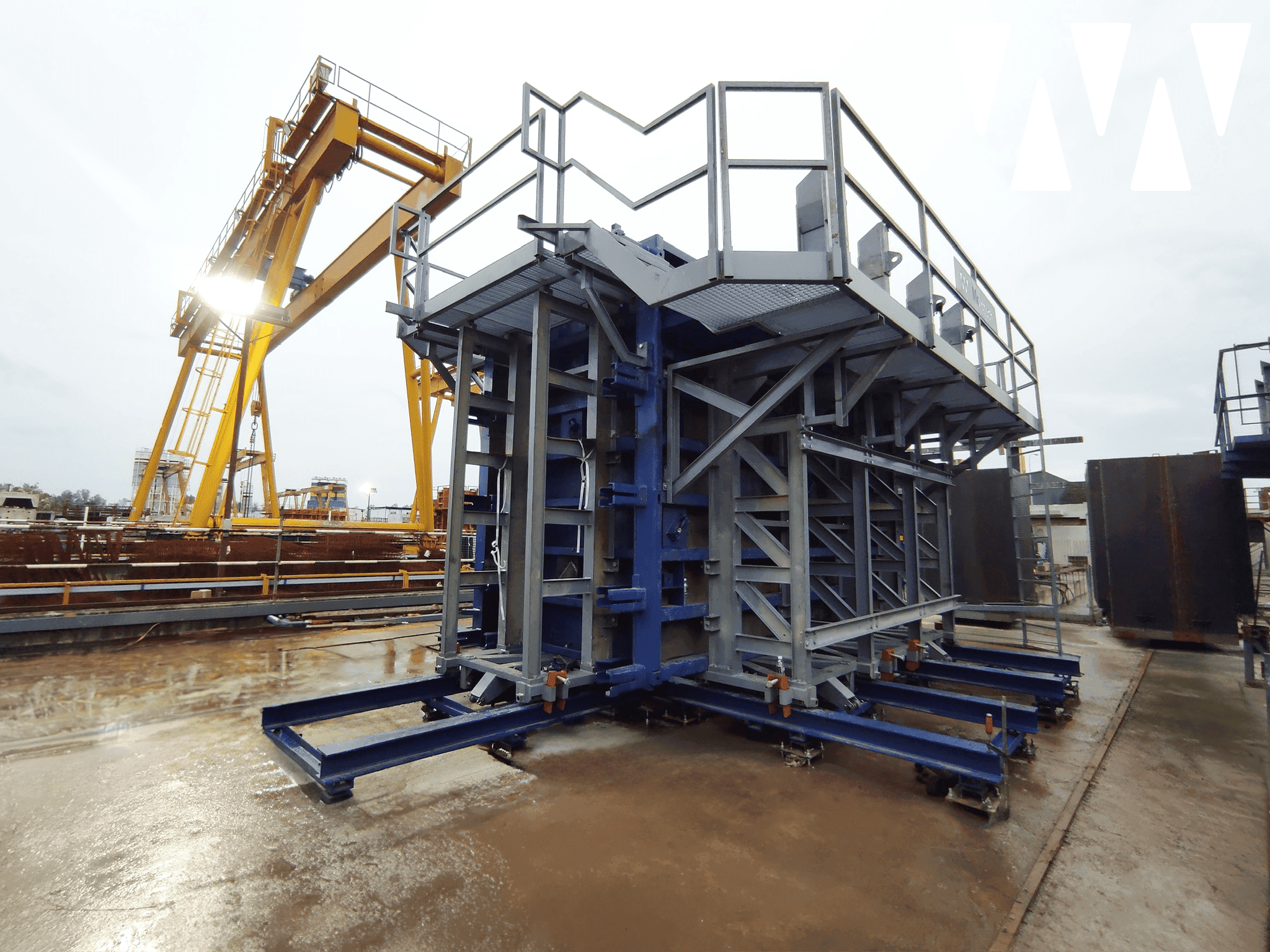

The new 2.95 x 4.5 x 2.8-meter mold has been developed for the production of complete modules, including slab and walls, adapting to various modular specifications according to the client’s needs.

Within its main features:

???? Versatile dimensions: Length of 4.5 meters, width of 2.95 meters and variable height of up to 2.8 meters.

???? Integration of structural details: Formwork for doors, windows and ceilings, guaranteeing precision in each module.

???? Advanced hydraulic system: Promote the opening and closing of the mold with precision and safety.

???? Optimized structure: Composed of two independent inner cores, exterior sides, base and accessories that ensure the correct conformation of each piece.

Applications and benefits

This manufacturing system is ideal for hotels, hospitals, student residences, prisons, residential buildings, etc., where modular construction provides a competitive advantage.

Moldtech and the vision of the future of construction

The industrialization of the construction sector is the present and the future. Moldtech has identified this evolution and positions itself as a benchmark in the development of solutions that not only improve construction processes, but also respond to the growing demand for sustainable, profitable and high-performance infrastructures.

Moldtech is committed to automation and digitalization in the manufacturing of prefabricated elements, ensuring greater precision and quality control at each stage of the process. This vision allows reducing construction times and associated costs, offering builders a faster, more productive alternative with less environmental impact.

The development of molds such as the 3D Mold – PBU responds to the need for flexibility and scalability in modern construction projects. Thanks to its modular and adaptable design, specific modules can be manufactured for different uses, guaranteeing personalized solutions without compromising quality or efficiency.

Moldtech also works on the integration of technologies and the manufacture of prefabricated structures using advanced processes that optimize material performance and minimize waste.

Commitment to industrialized construction

With this new delivery, Moldtech reaffirms its commitment to the development of advanced and high-level solutions for precast construction.

Because precast is no longer just a trend, it is a necessity.

???? If construction is a puzzle, Moldtech gives you the key piece.

???? Moldtech continues to lead the evolution of modular construction with tailored solutions.