Moldtech has recently completed the delivery of a new tilting table to a leading Spanish company specialized in the construction of high-class housing.

The client, with more than 50 years of experience, stands out in the construction sector for offering precast concrete structures which ensure reliability and quality. This company is focused on projects of high-class and luxury turnkey homes, both in Spain and in France.

The company promotes the fast construction velocity and operability in its processes, managing to reduce execution costs without compromising the safety and quality of the materials and the result. With an experienced team, this mentioned company adapts its knowledge and know-how to the specific needs on each project, guaranteeing exceptional service.

Committed to change and customer satisfaction, Moldtech and its customer look for a continuous profitability and success in the field of the precast construction within the highest construction standards with “Passivhaus” certification.

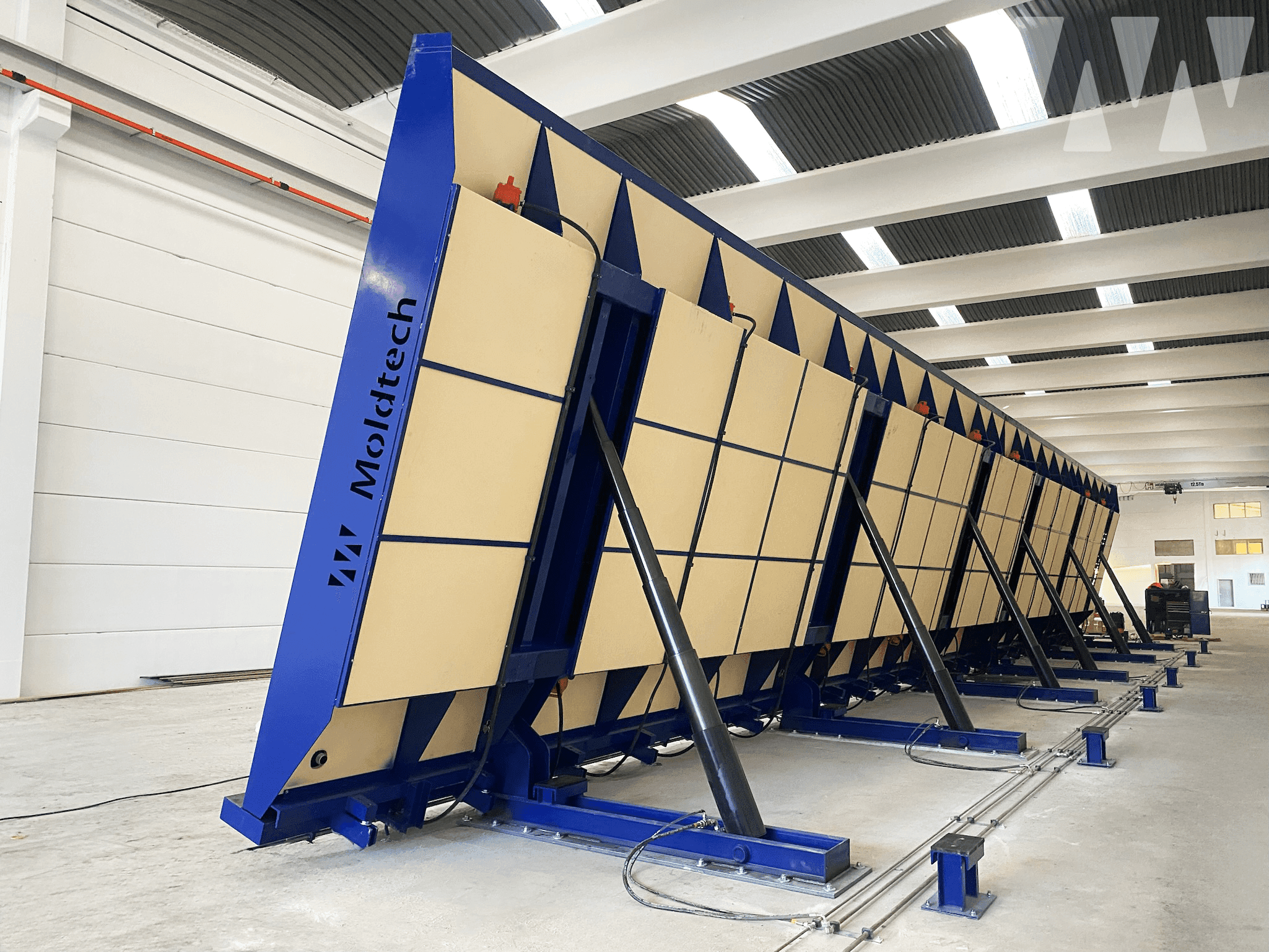

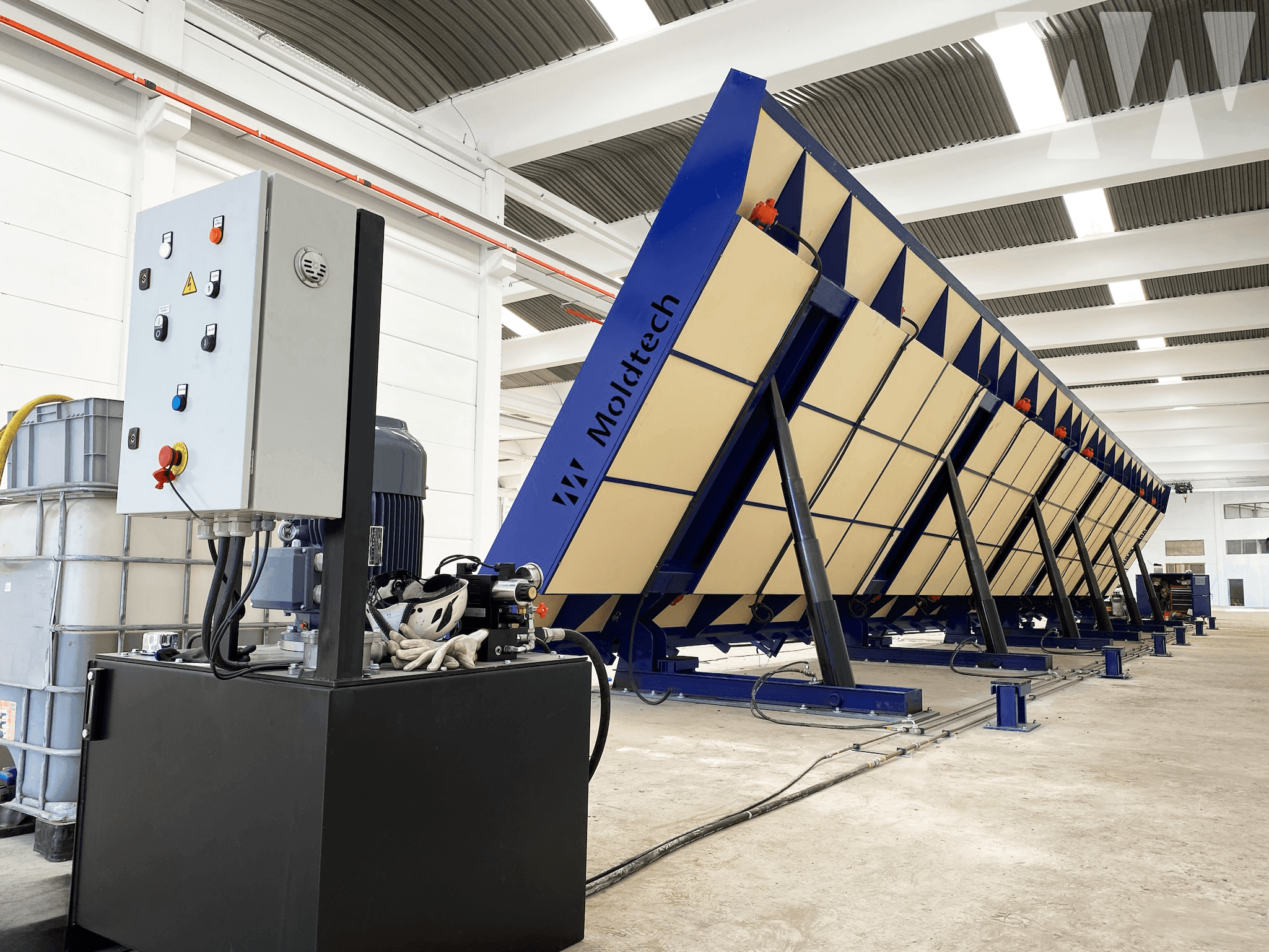

Moldtech tilting tables are equipped with hydraulic telescopic cylinders that allow efficient tilting operation, facilitating the demoulding of the panels without compromising the curing time of the concrete. In addition, integrated vibration and heating system speeds up this mentioned curing process, while adjustable bands and magnetic shuttering systems offer a high versatility to produce a big number of different panel dimensions and shapes.

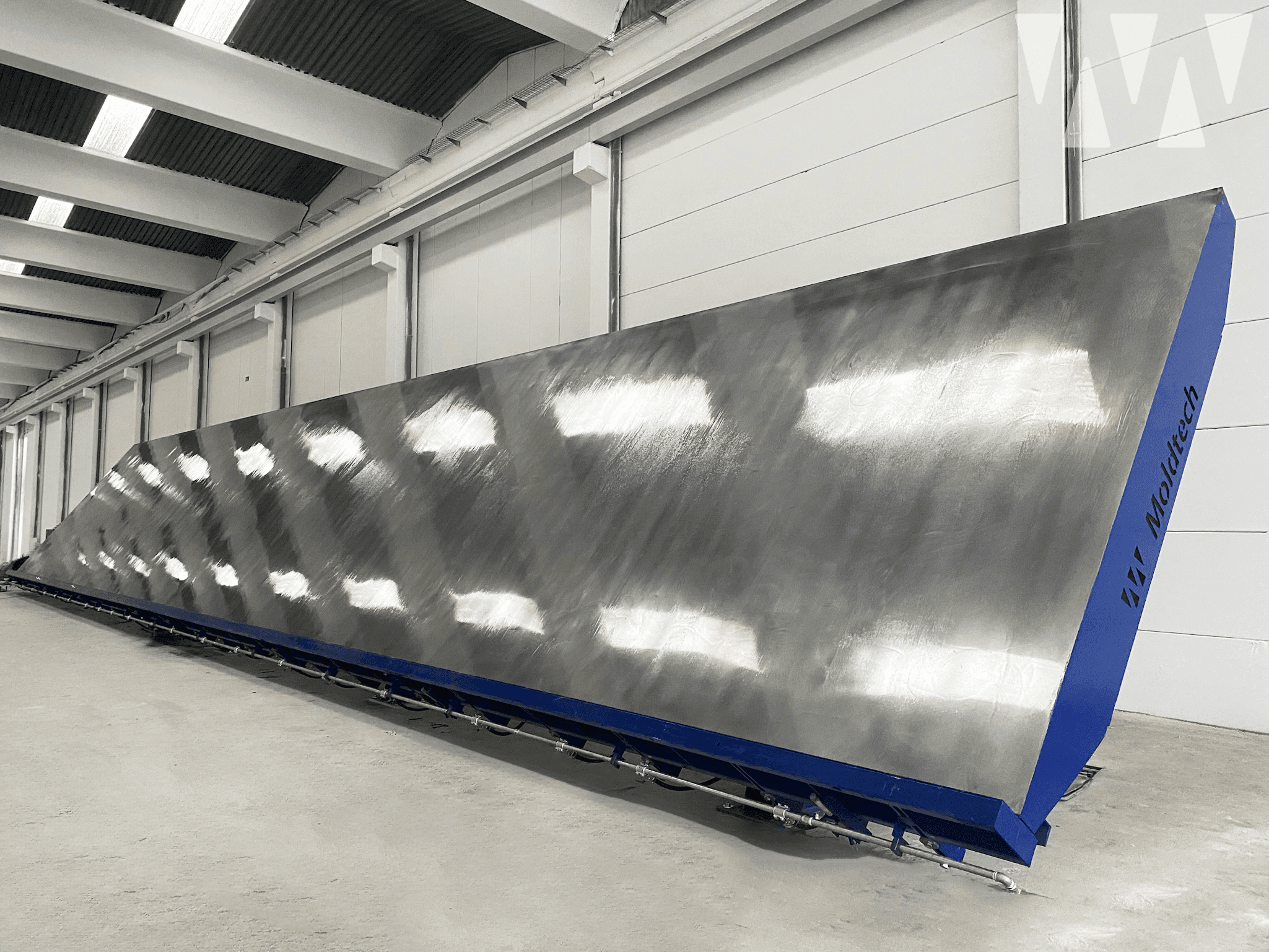

This new 26 metres long and 4.2 metres width tilting table has been designed to optimise the production of high quality precast concrete panels for residential buildings.

The table has a heating system, consisting of finned pipes for hot water and thermal insulation system that optimises and reduces energy consumption preventing heat losses underneath the table.

This specific table has a mechanically height-adjustable lower longitudinal band, which allows the production of different thickness of the panels, between 160 and 280 mm. The table is tilted by means of hydraulic cylinders, driven by a hydraulic unit and a main electric control board.

This equipment not only improves the quality of the final product, due to the final polish mirror finish, but also reduces the number of labours required to produce the final wall panels, it also enables efficient customising of the production of precasted elements, which are key point for modern building and infrastructure construction.

For more information about Moldtech‘s solutions and their impact on the construction industry, please visit the company’s website or contact its support team directly. Moldtech remains committed to developing advanced technologies that facilitate and enhance the construction of homes, ensuring efficiency and quality in every project delivered.