Moldtech, a leading company in innovative solutions for the precast concrete industry, has developed a relevant product: a turning system for double walls that promises to transform the construction process.

To enhance the efficiency of production of double walls with unprecedented precision and speed, this innovation from Moldtech is expected to drive the development of high-end construction projects and encourage the adoption of more advanced and sustainable construction practices in the country.

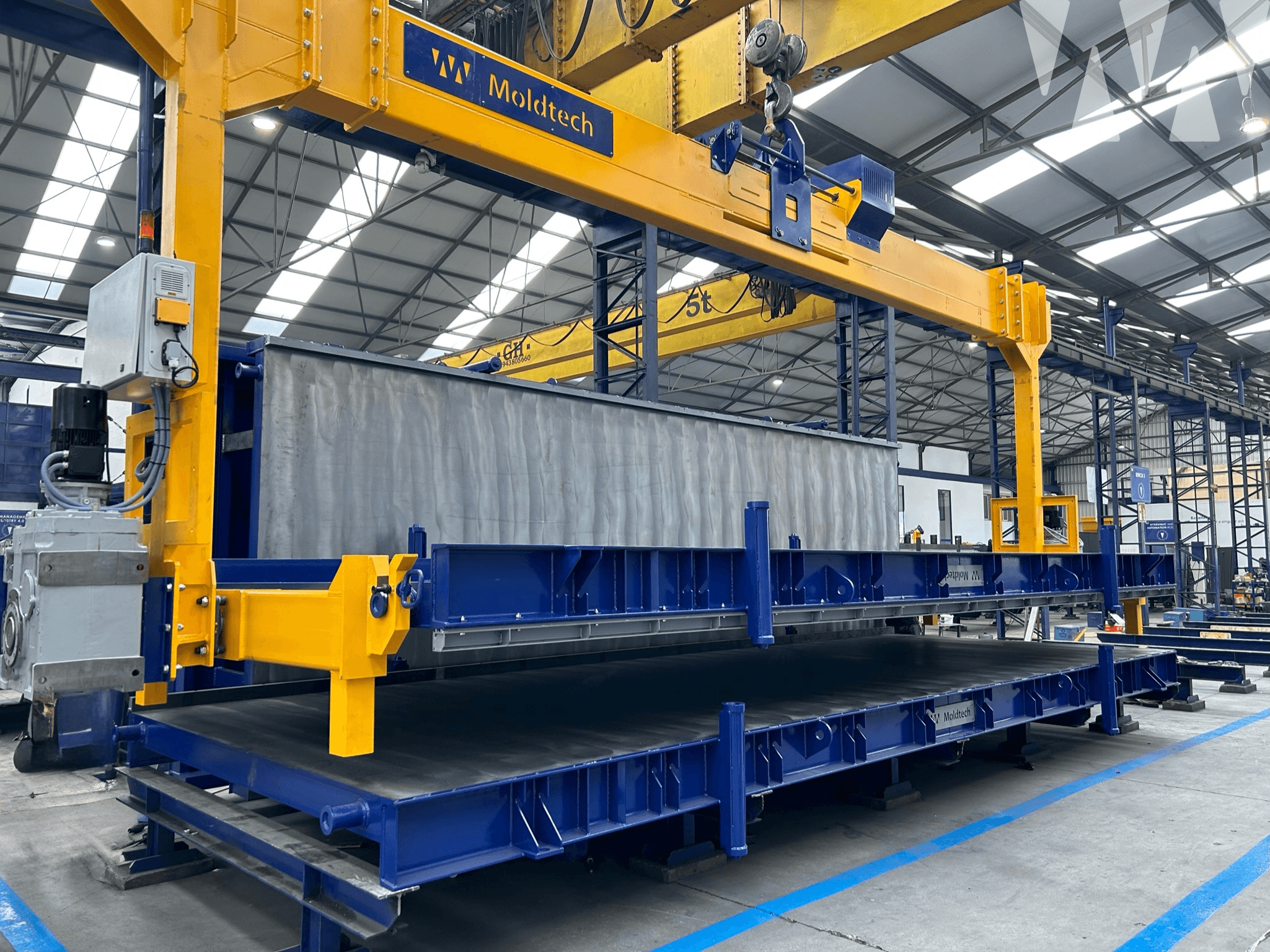

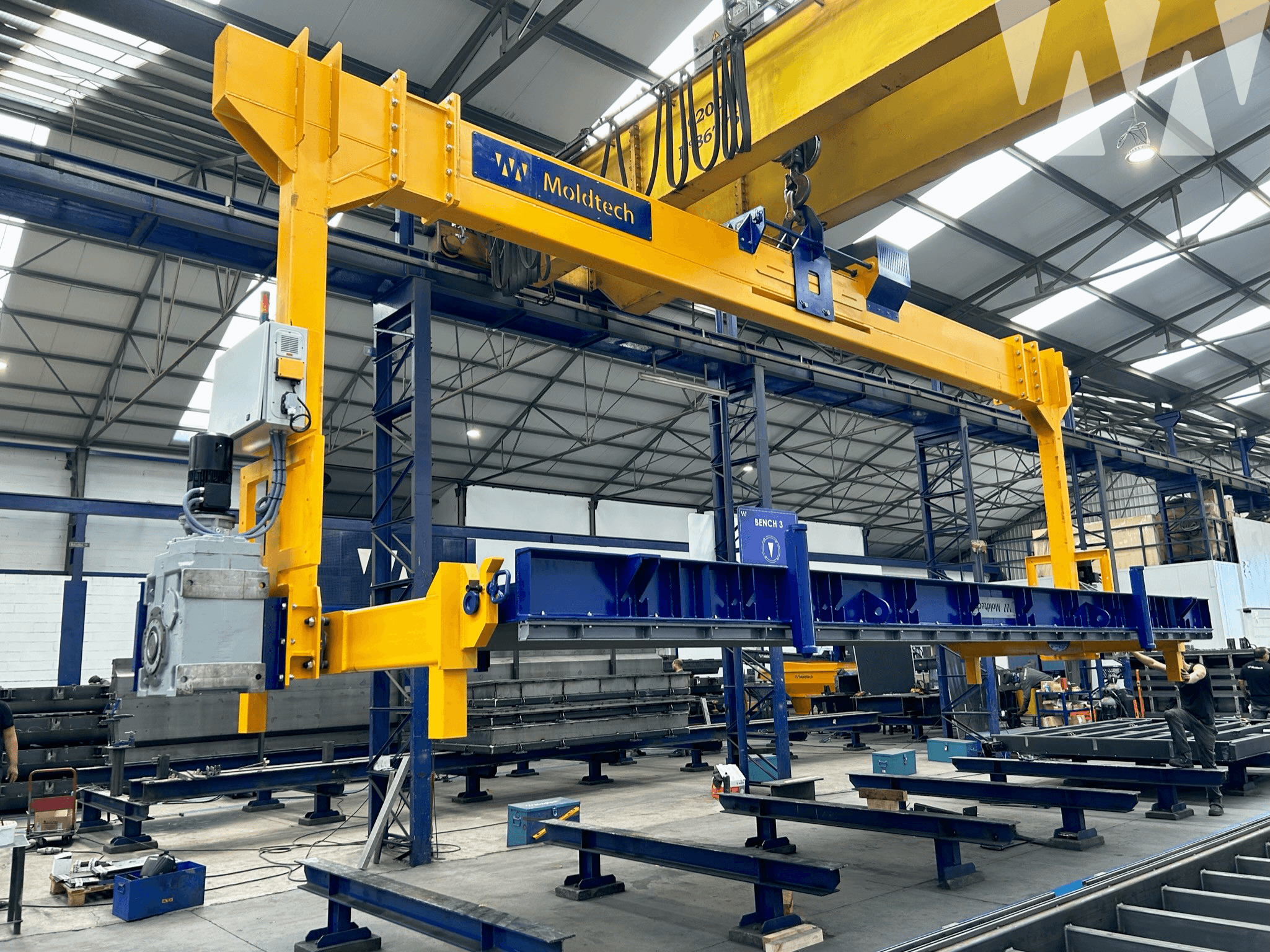

This system integrates stackable pallets, a 180º turner and a vibration station to speed up performance and quality in the production of double walls.

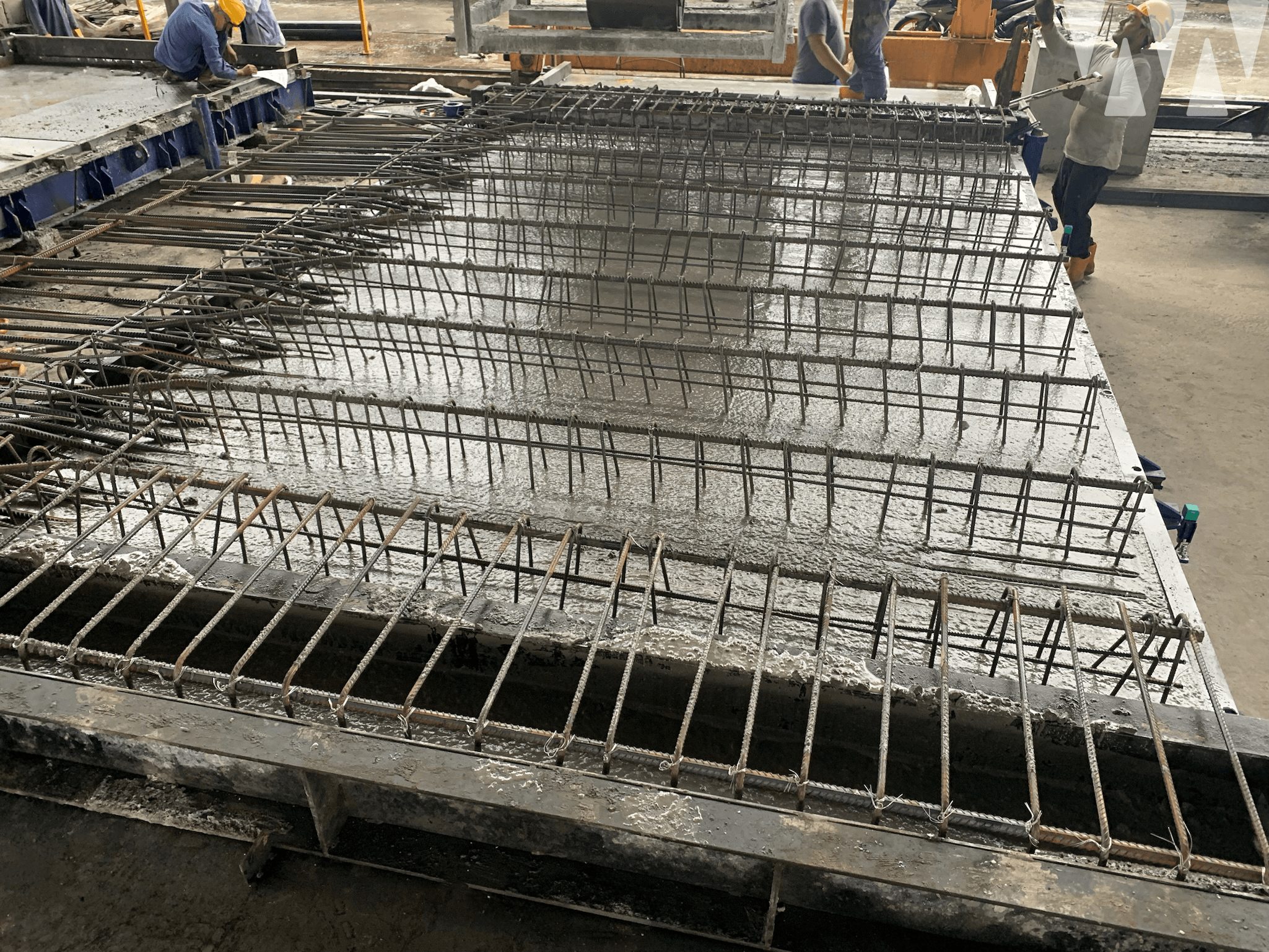

The process starts with placing the pallet for the first slab at the preparation station, where it is assembled with the necessary structure. Subsequently, the pallet is moved to the vibration station to ensure adequate compaction of the concrete using electric vibrators and frequency converters.

Once poured, the pallet is removed and stacked for the curing process. Meanwhile, another pallet is prepared with formwork for the second slab, placed on the vibration station and the concrete is poured.

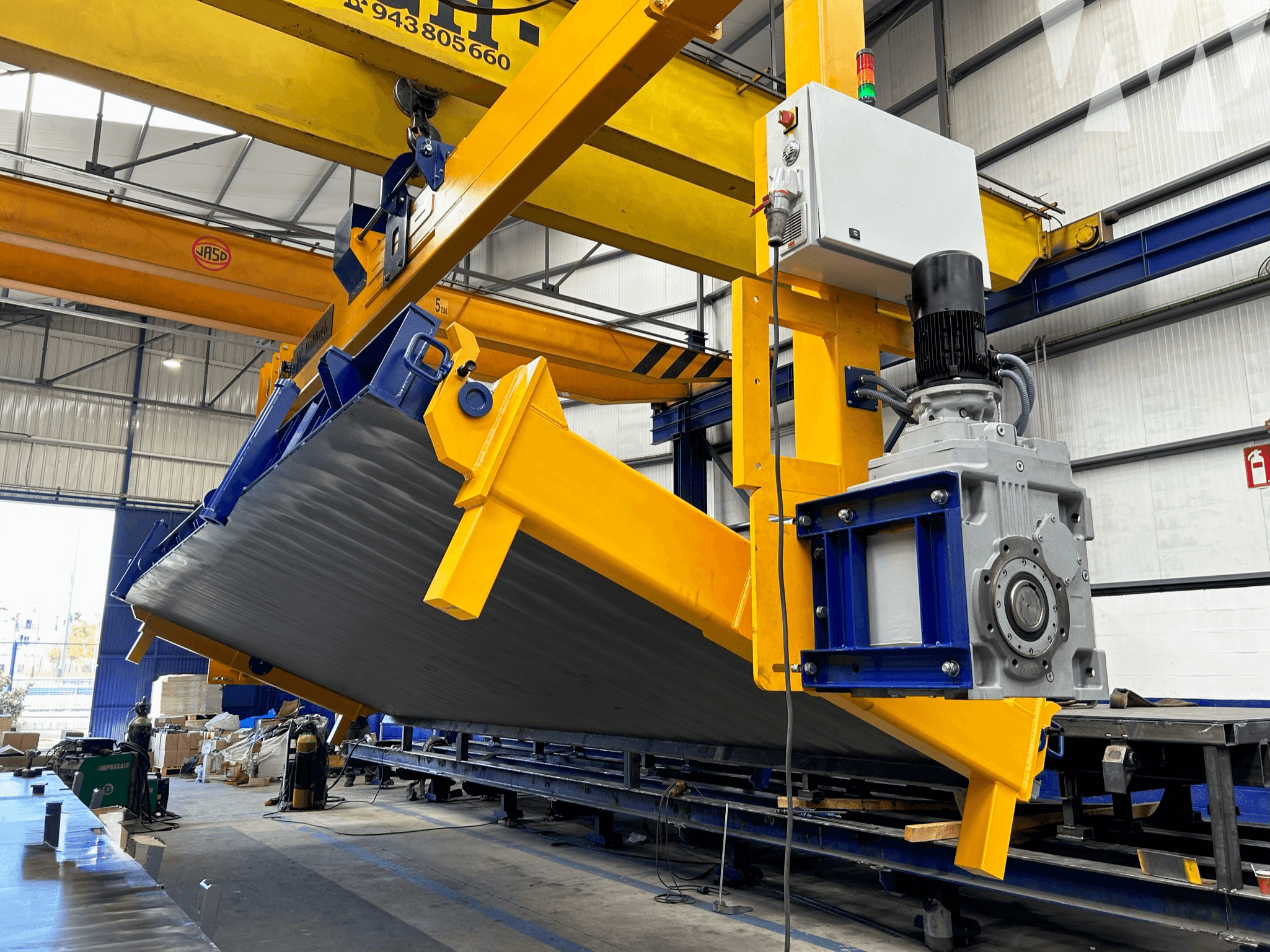

What is truly innovative and advanced occurs when the first pallet, already cured, is removed from the stackable zone and prepared with fixing bars to be flipped 180º with the turner. Then it is placed on the second pallet, where the concrete is still fresh, allowing both slabs to join together forming a complete double wall.

This system not only offers the possibility of adjusting different double wall thicknesses using spacer bars between the pallet legs, but also ensures an effective and precise process.

Once the concrete is adequately compacted, the fixing bars are removed and the upper pallet is unmolded with the turner, leaving the complete double wall in the second pallet.

Besides Moldtech offers the possibility of progressively increasing this system with additional equipment, until implementing a complete pallet circulation system, providing a versatile solution for double wall or slabs construction projects.

With this new proposal, Moldtech reaffirms its skill and impeccable execution in the manufacture of equipment for precast concrete, which substantially improves construction processes and opens new possibilities for the industry, offering productive, precise, and high-quality solutions.