Moldtech and our partner in Chile join forces to take a step forward in the 3D modular construction (PPVC) and together, we achieve the development of this innovative system for housing construction in Latin America.

The company of our charismatic and loyal client was created in 1972 as a concrete factory in Chile, becoming a national leader in this product line and currently having four manufacturing plants.

In order to remain at the forefront, and always looking for innovative products through the use of precast concrete, our client has incorporated European technologies where Moldtech plays its role as a strategic partner.

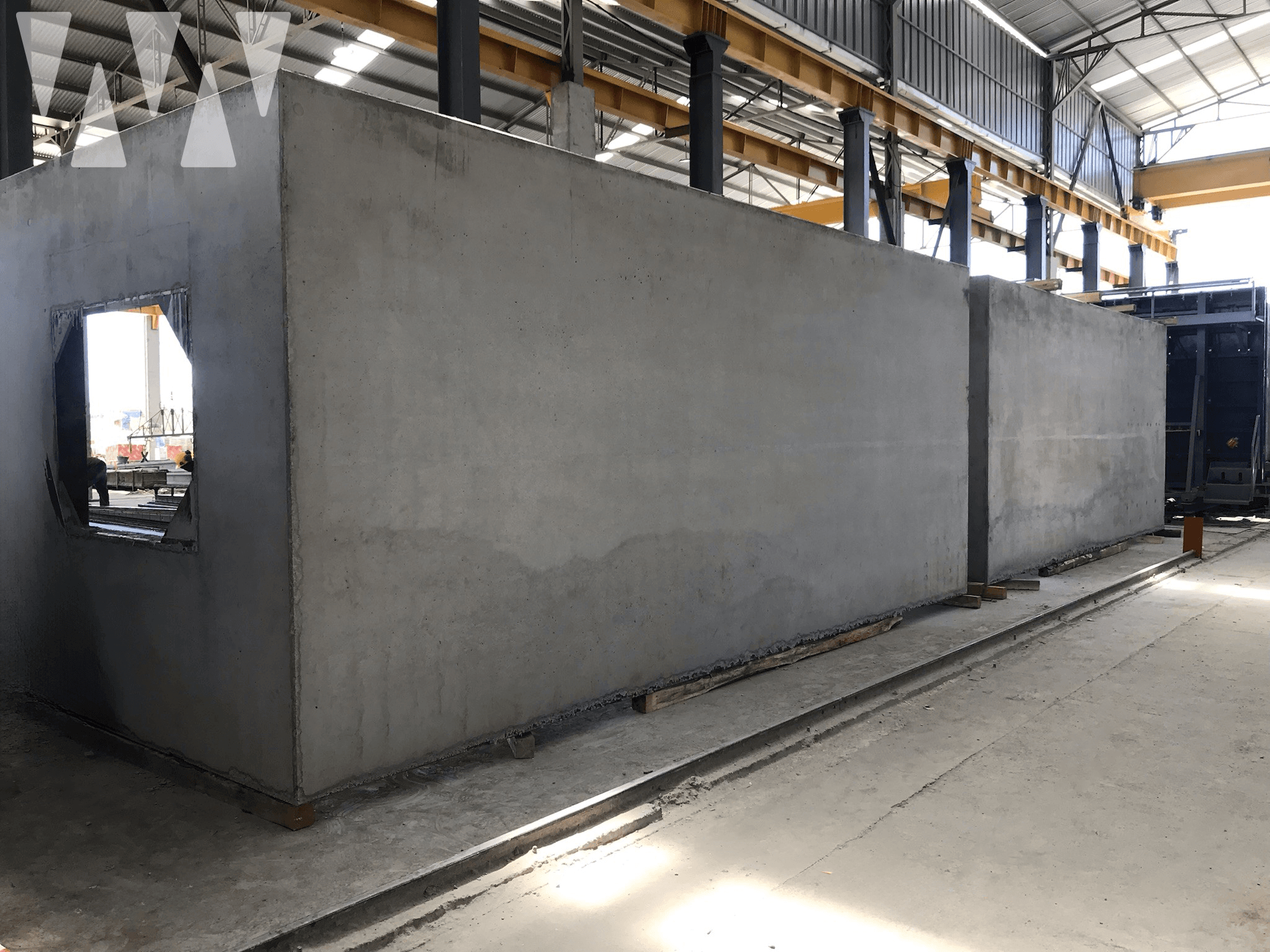

This concrete modular housing is efficient and represents a sustainable construction by using precast concrete modules manufactured in specialized factories. These precast concrete modules allow the client to get a great and wide versatility in architectural design, from single-family houses to multi-storey buildings.

The high production capacity in this construction process is achieved by a significant reduction of the construction timing and the possibility of working in a controlled environment at the factory during the whole year. In addition, these concrete modules offer good thermal insulation, contributing in this way to energy savings in heating and cooling costs.

The durability of the concrete also reduces potential long-term maintenance costs. Although the initial investment may be similar to the traditional construction, the efficiency of the process will result in an overall reduction of the general costs.

Concrete modular homes incorporate modern technologies and allow the final customisation of the different designs to suit the wide range of individual preferences.

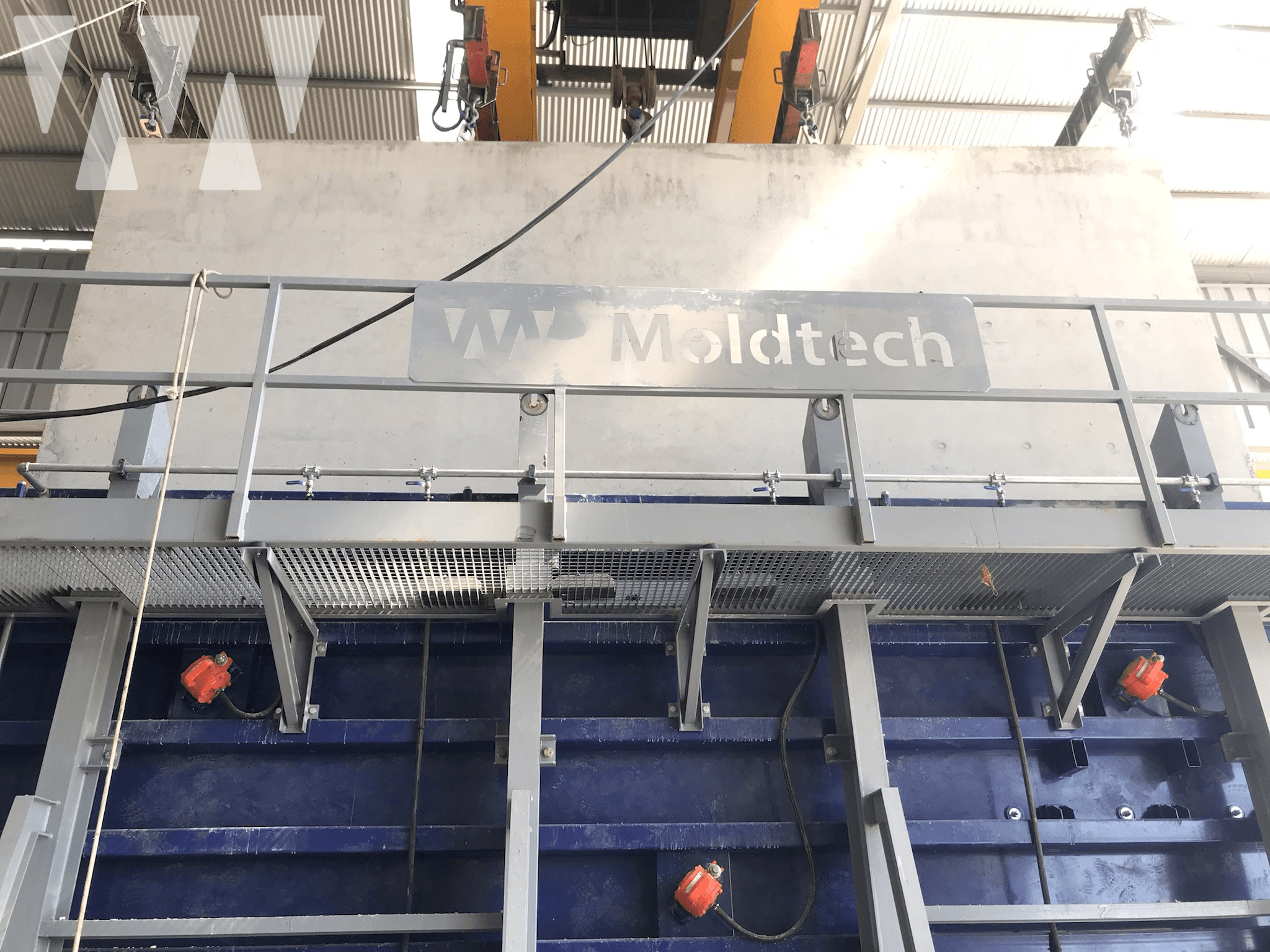

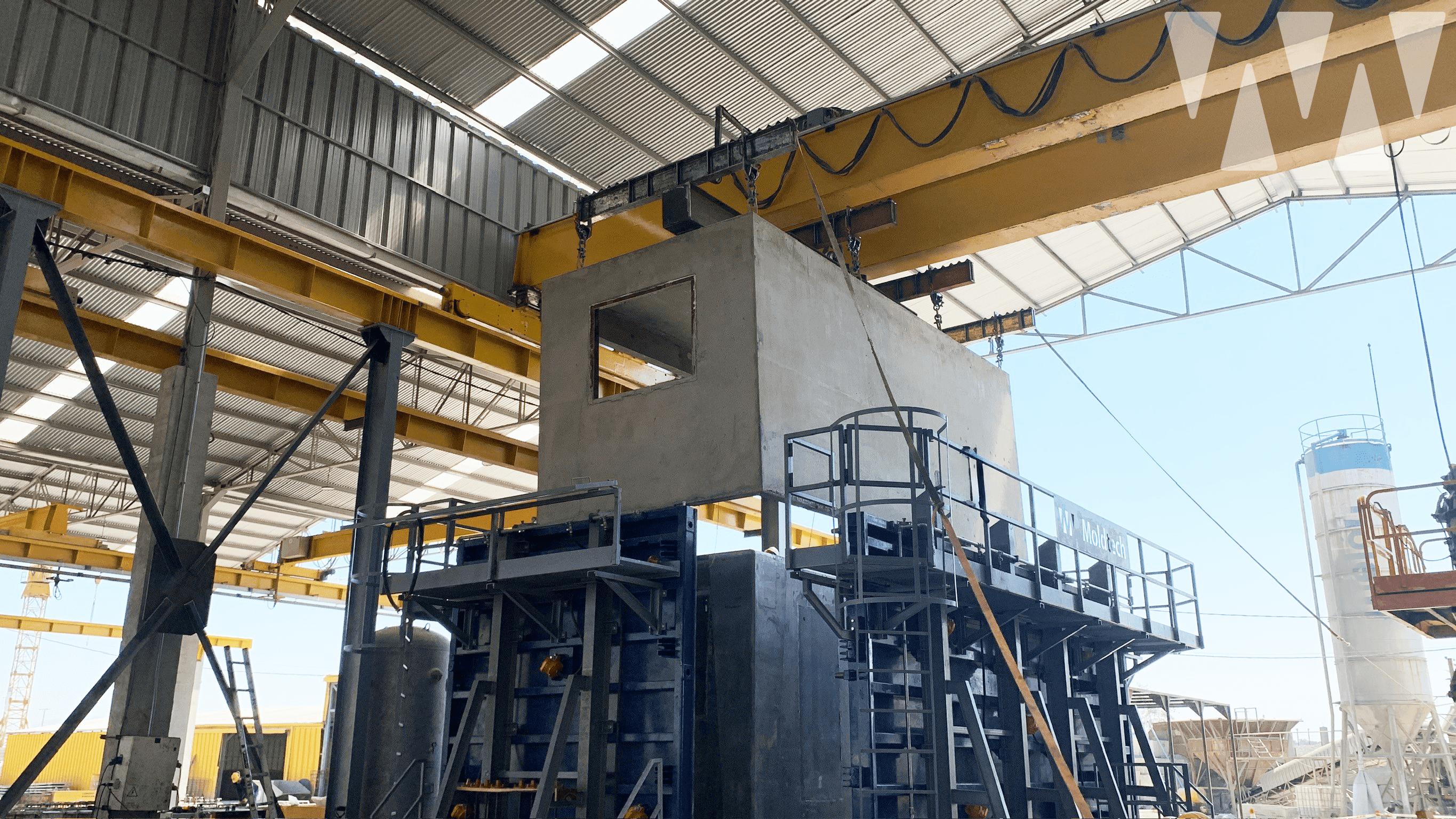

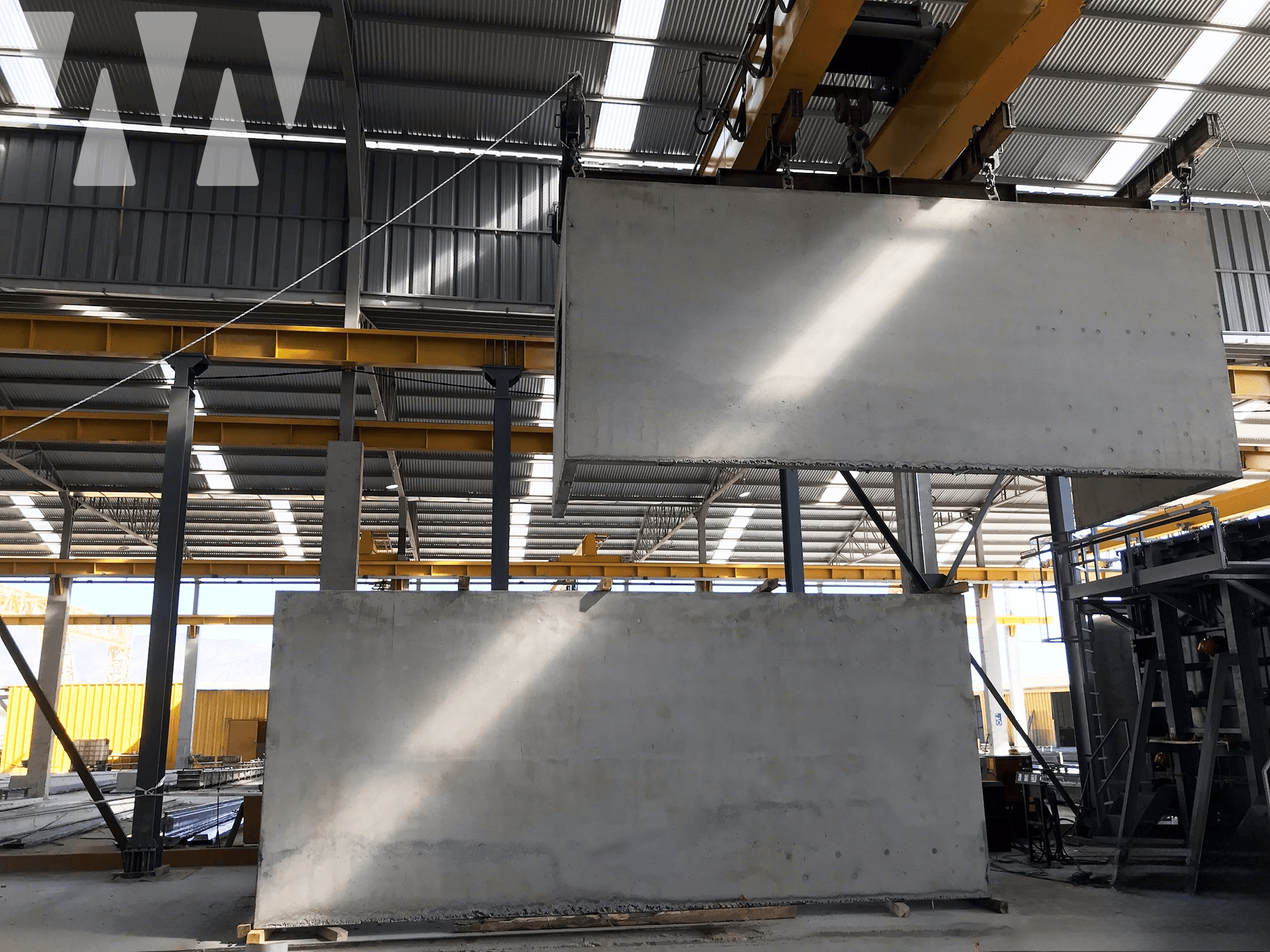

In this project, MOLDTECH has designed and supplied a modular 3D mould to cast one-piece precast 3D modules with different dimension (from 5 m length to 7 meters x 3 m), including slab and walls.

The mould is designed according to the specific dimensions and requirements provided by the customer. The main features of this mould are the following:

- Variable length of the manufactured piece between 5 and 7 meters.

- Fixed width of the manufactured module of 3 meters.

- The height of the precast module could be adjusted from 2,50 to 3 meters.

- Suitable formwork for doors, windows, and ceilings.

- Hydraulic system for the opening/closing system of the mould.

- Pneumatic vibration system.

This strategic collaboration between Moldtech and its partner in Chile is a breakthrough in the Chilean construction industry. Due to the combination of their expertise and resources, this company is taking a bold step into the future of industrialized construction, leading the way to a more efficient, sustainable, and visionary way of building. This new chapter in the construction history promises not only to transform the way of building these residential houses, but also to set the stage for a new standard of innovation in the sector.