A story of technological breakthroughs and strategic alliances that transform the sector

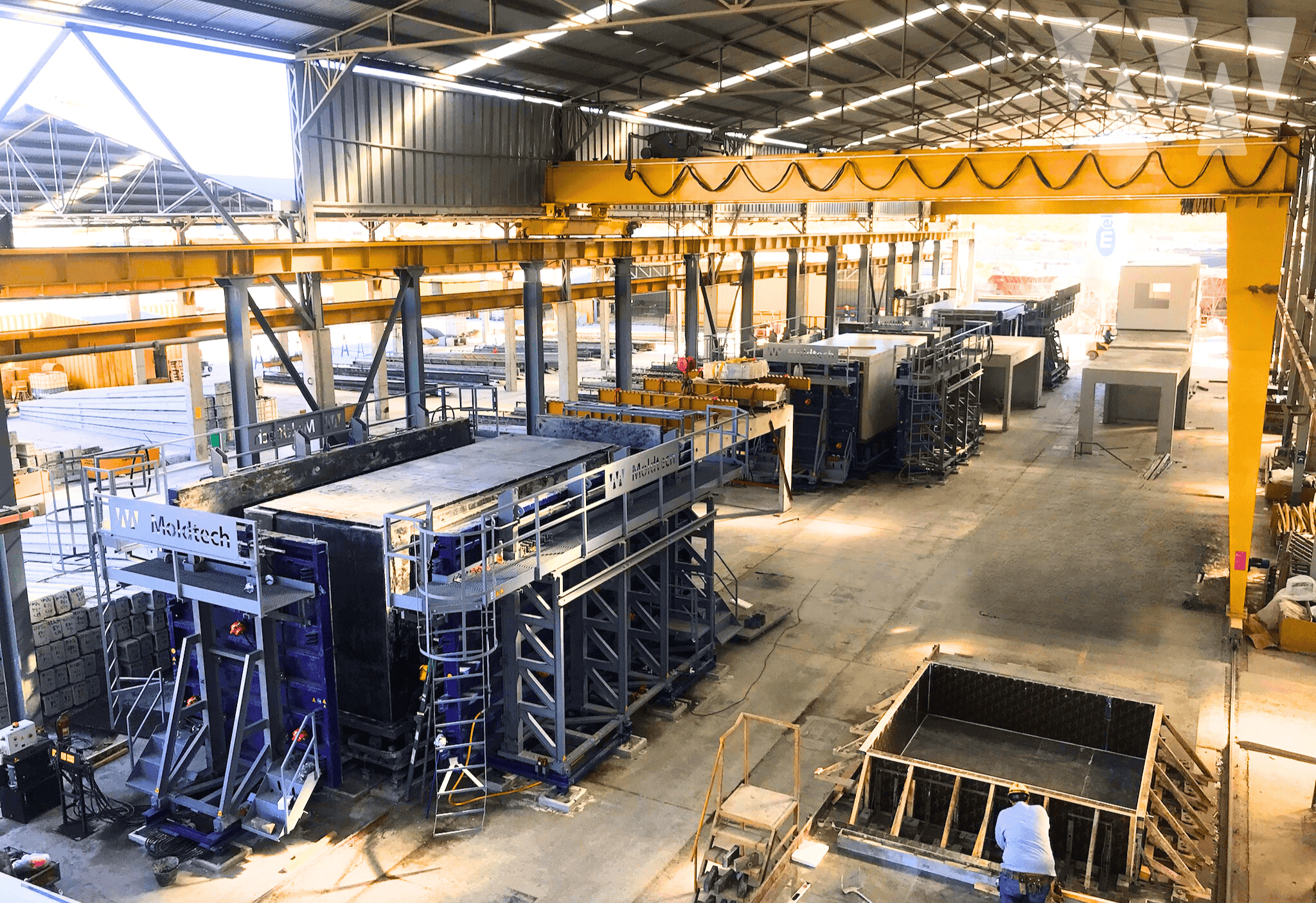

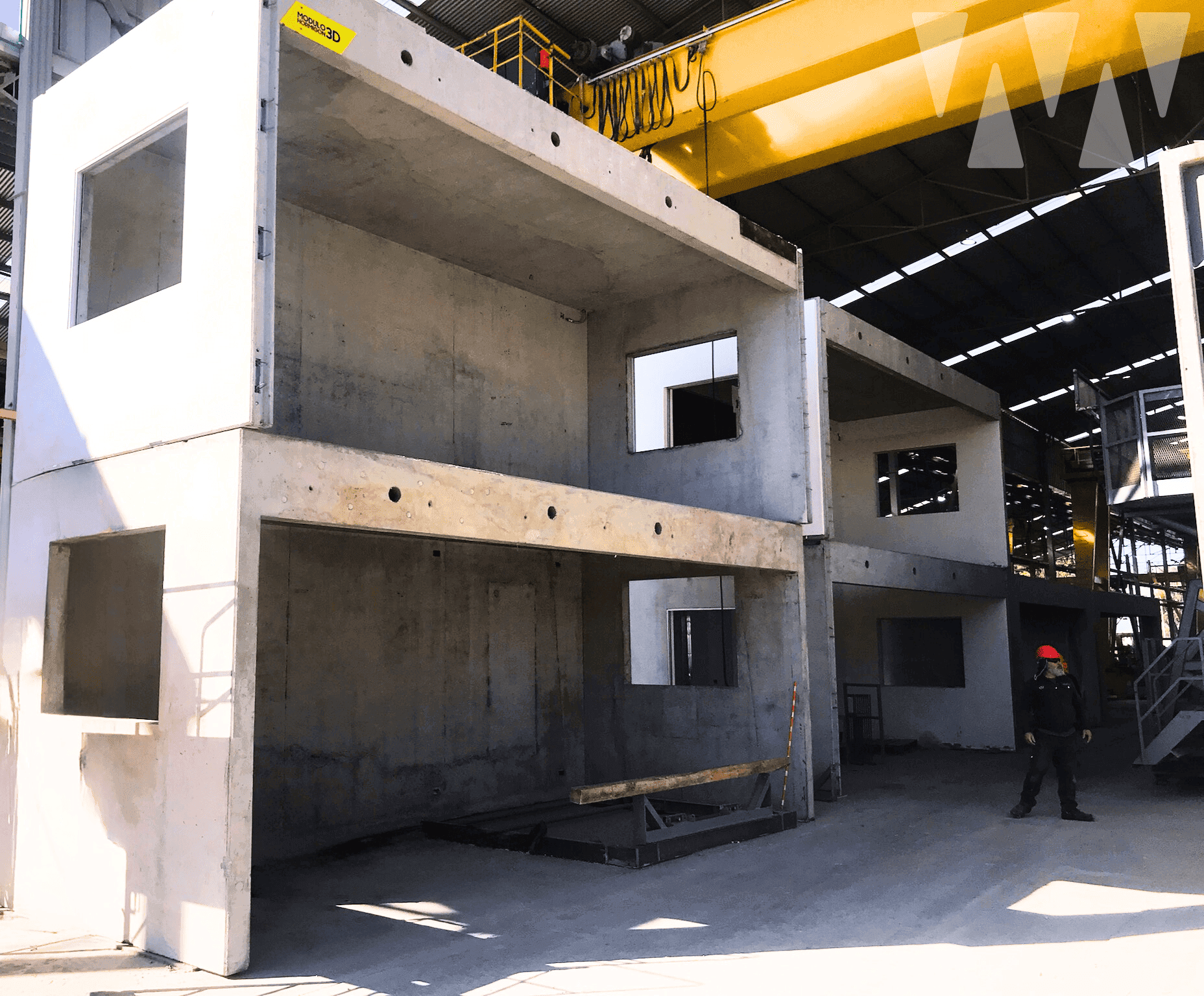

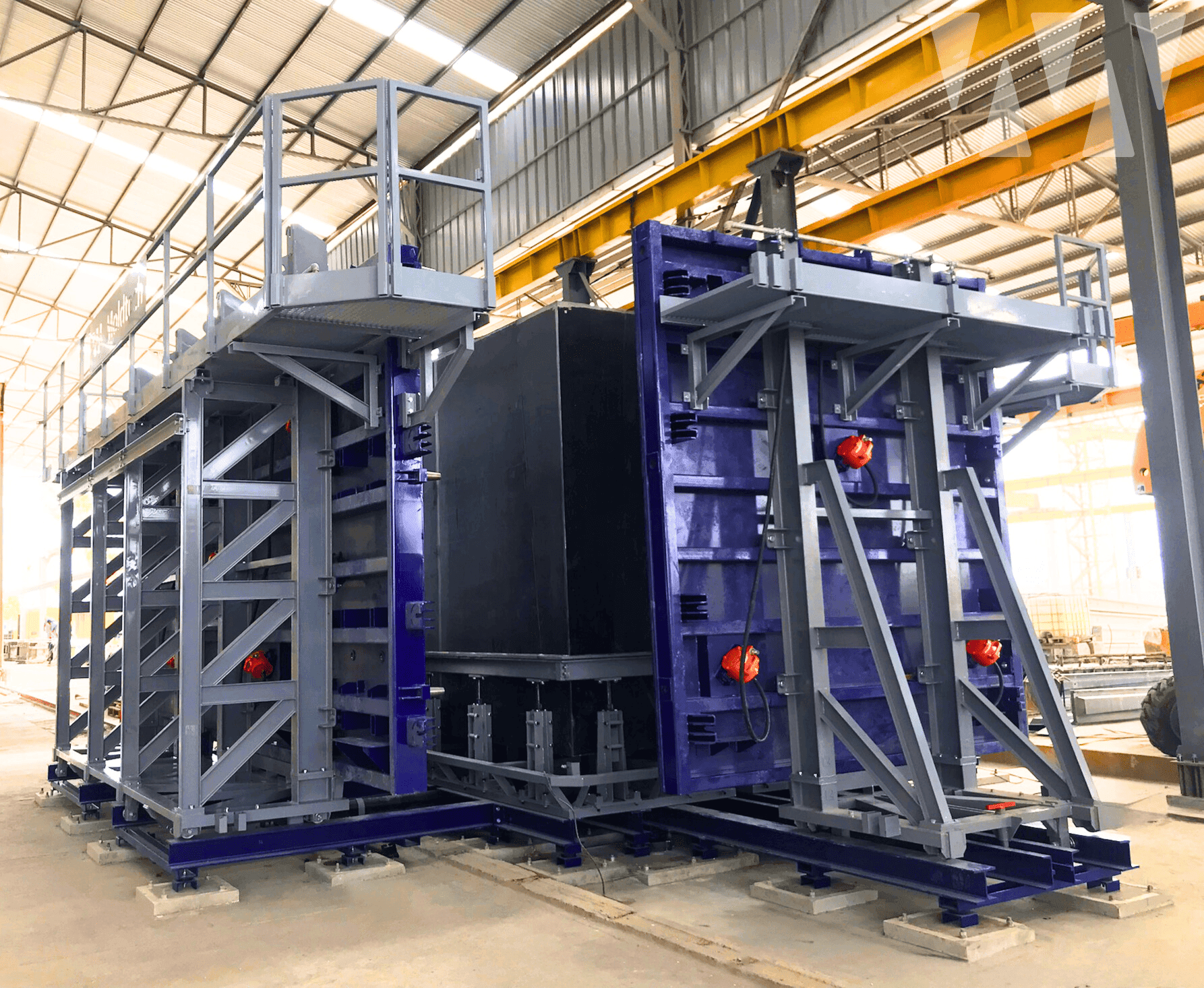

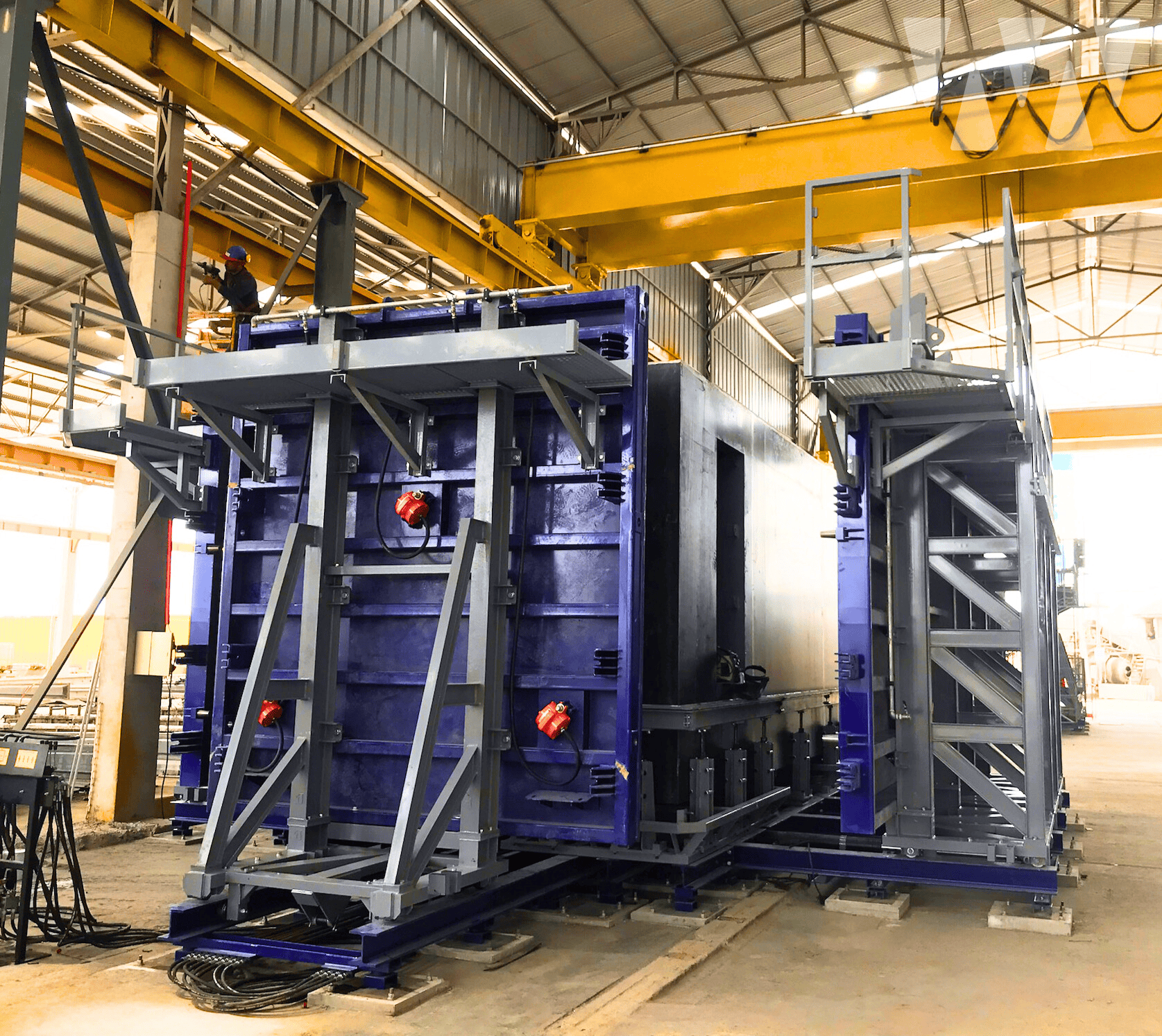

Industrialised construction has come a long way, from the first modular building systems to today’s complex solutions. Technology and Prefabrication in the 21st century, and the rise of modular systems has taken industrialised construction to a new level. The client, specialising in modular solutions, has integrated 3D moulds supplied by Moldtech, allowing complete structures to be created quickly and accurately.

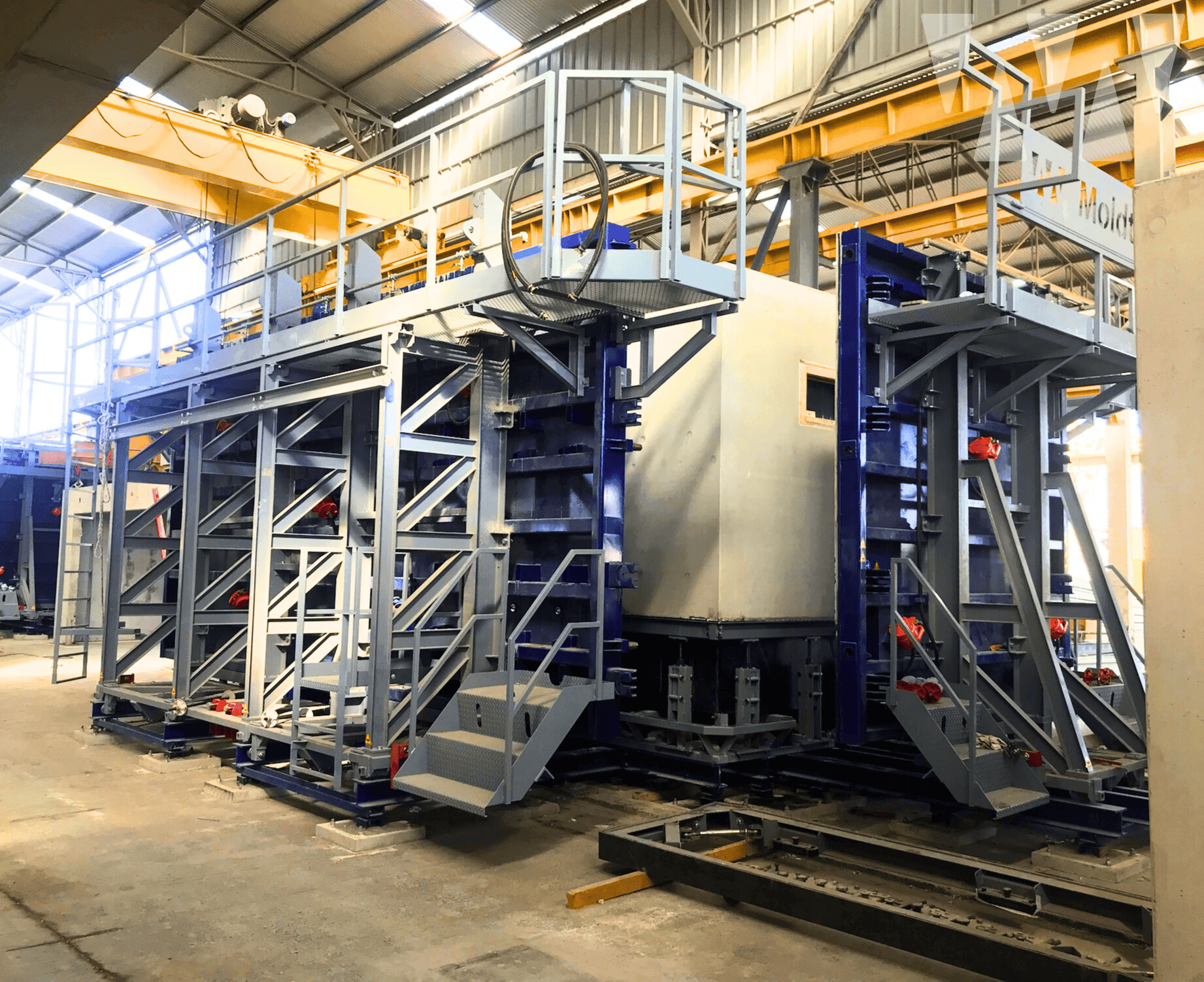

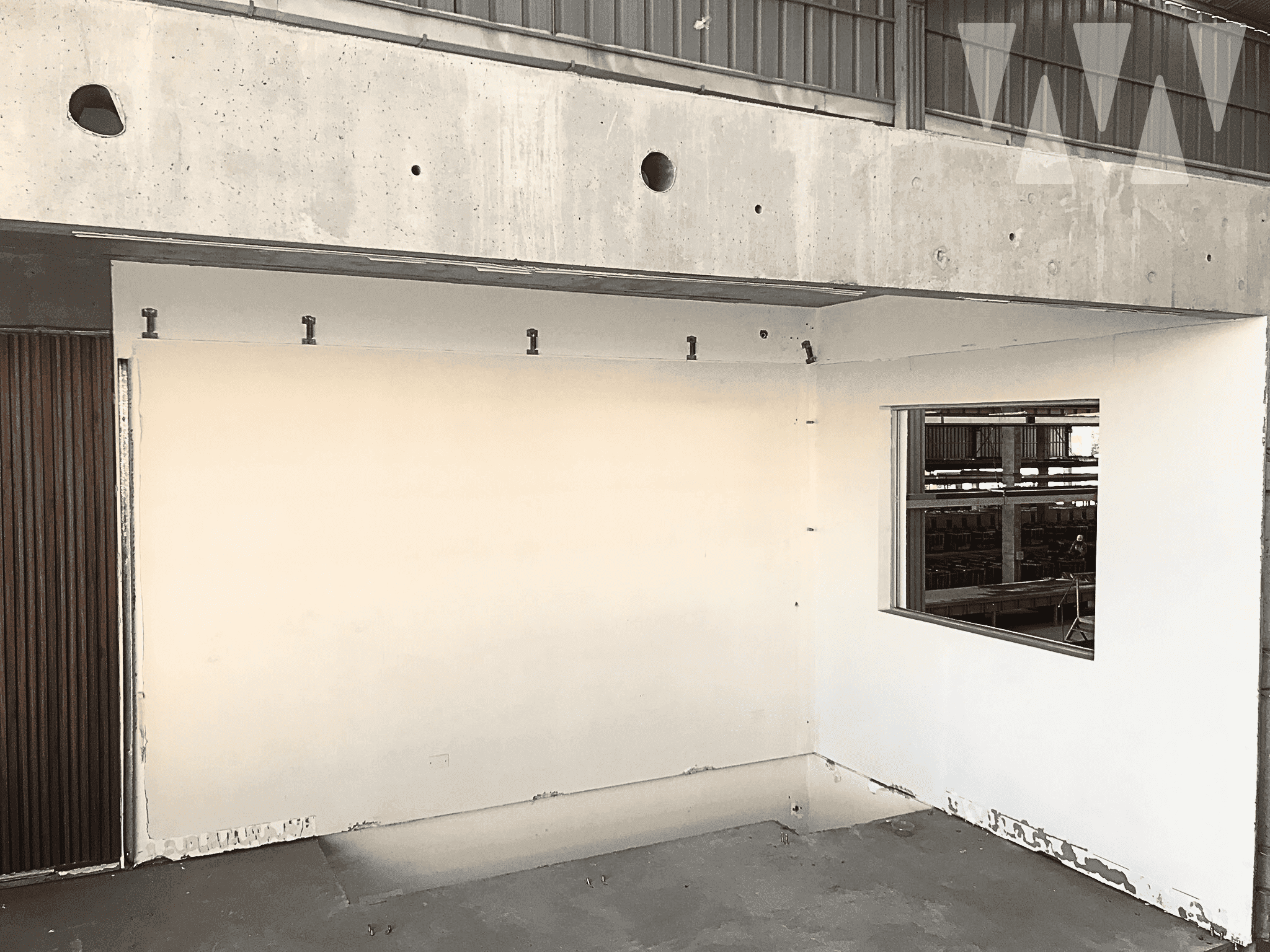

Technical Details of the 3D Mould for Modular Housing (5 to 7 x 3 m) The 3D mould for modular housing from 5 to 7 x 3 metres is designed to manufacture prefabricated housing modules of non-prestressed concrete, integrating the slab and walls in a single piece. Its design adapts to the specifications and needs provided by the client, offering a versatile and high quality solution.

Main features:

- Adaptable Dimensions:

- Length of the manufactured piece: variable between 5 and 7 metres.

- Width of the manufactured part: fixed at 3 metres.

- Height of the manufactured piece: variable between 2.50 and 3 metres.

- Elements Incorporated:

- Formwork for doors, windows and roofs, allowing customised configurations.

- Operating Systems:

- Hydraulic system for opening and closing the mould, ensuring efficiency and safety during the manufacturing and demoulding process.

- Hydraulic system for the retraction of the inner mould or “noyo”, ensuring the release of the concrete part for demoulding.

- Pneumatic vibration system to ensure optimum compaction of concrete and improve structural quality.

Commitment to the Future, and Innovation in Every Project, 3D moulds allow our client to produce modular elements with customisable configurations for residential projects. The collaboration between the client and Moldtech strengthens both companies’ commitment to developing advanced solutions for modular construction. This integrated approach redefines the industry, making the process more productive, adaptable and environmentally friendly.

Modular construction can reduce execution times by up to 50%, reducing on-site assembly times dramatically compared to panel systems, reducing the environmental impact of a construction site, reducing the financial costs of the project and increasing production capacity in annual cycles, which translates into higher business profits. In addition, the modular construction system reduces waste generated on site by up to 90%, thanks to controlled manufacturing in industrial environments. When we talk about sustainability, we talk about modular architecture.

Looking Ahead With the use of state-of-the-art technologies and strong strategic alliances, Moldtech accompanies its customers to lead the industrialised construction of the future, offering innovative solutions that surpass today’s standards.