Are you looking to maximise productivity in the manufacture of precast concrete elements?

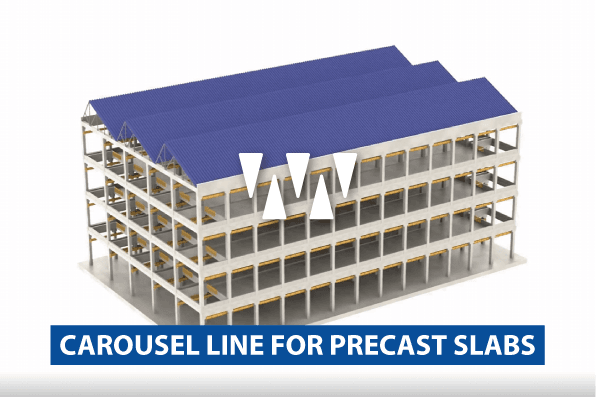

Discover this video for our fully automated rotary system for the production of precast panels, a high-performance solution that can achieve between 200 and 3,000 m² per shift.

This pallet circulation line divides the manufacturing process into independent phases, allowing for a continuous, precise and optimised flow. Each pallet moves automatically between work stations, ensuring total control, reduced downtime and increased operational efficiency.

Key working stations of the system:

- Cleaning and application of release agent

- Automatic plotting

- Placement of formwork, embedded elements and accessories

- Positioning of reinforcing bars

- Transversal movement with automated transborder

- Verification by high-precision laser projection

- Concrete pouring and vibration

- Curing in controlled curing chambers

- Hydraulic tilting for final demoulding

Thanks to its modular design, this line can be adapted to different productivity levels and customised configurations according to the needs of your precast plant. An ideal solution for precast manufacturers looking for automatic processes, reduce costs and improve the quality of the final product. Industrial manufacturing of the future, today.