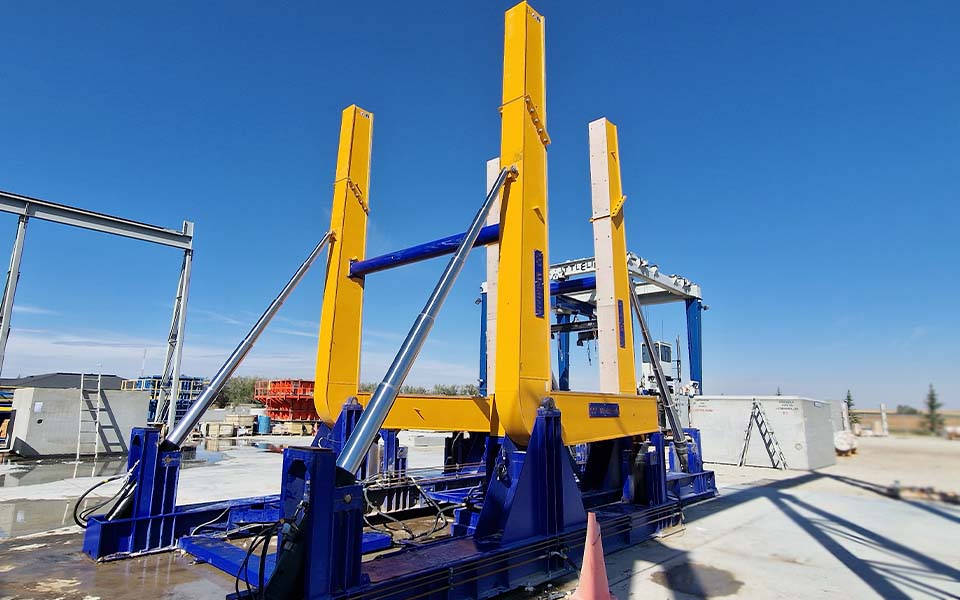

Moldtech has commissioned the 50-tonne capacity turning machine in Alberta, Canada.

The turning machine is designed to turn 180º 3D precast concrete elements, from the de-moulding position to the final position of placement on site.

This machine belongs to the auxiliary equipment category but fulfil an essential role in making certain operational tasks easier at the precast factory.

In this sense the turners can have a great impact when the casting position of the precast element is not the same as the final position the element will be placed at the job site. In the precast industry some products must be casted in an upside-down position for a variety of reasons like to obtain a better-quality finish of the casted element or because in the upside – down position the pouring process can be accomplished easier and faster.

All movements are performed by means of a hydraulic system composed of telescopic cylinders and a hydraulic power unit.

The maximum working capacity of the equipment is 50 tons. It is the most powerful turner device made at Moldtech up to today.

The maximum load capacity of the equipment has been designed considering the dimensions of the precast elements that our client needs to turn.

The machine consists of two 90° turners which, acting sequentially, allow a total rotation of 180°.

Video – Testing at Moldtech facilities